I wouldn't be so quick assuming everyone knows what you know. Apparently not "everyone else" does when stuff like this keeps showing up. Old TCP yes, the new coilover mounts on the lower control arm with the force close to the balljoint, where it should be. No rod ends are in bending. Griggs and Ron Morris designs are the same. As for the old TCP design and similar ones, show me a car driven on the street and track regularly that have these

suspension systems. So far I've only seen them in magazines, in-progress show-off threads, car shows, and manufacturer mock-ups. The link I provided showed you a failure, and that's a sub-500lb car. Besides, I wasn't arguing either method, just showing some info. Or should he plead ignorance in the event that those threads pop out of the arms? He asked for opinions, I'm giving them.

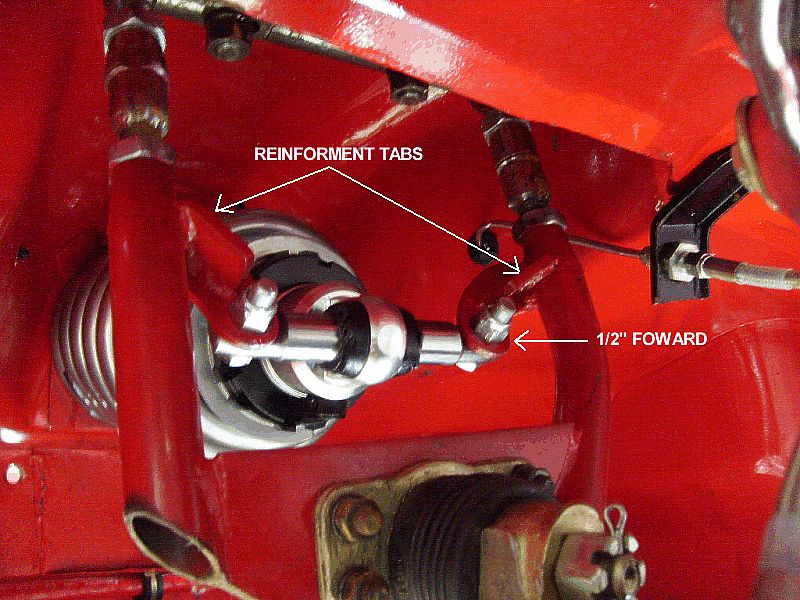

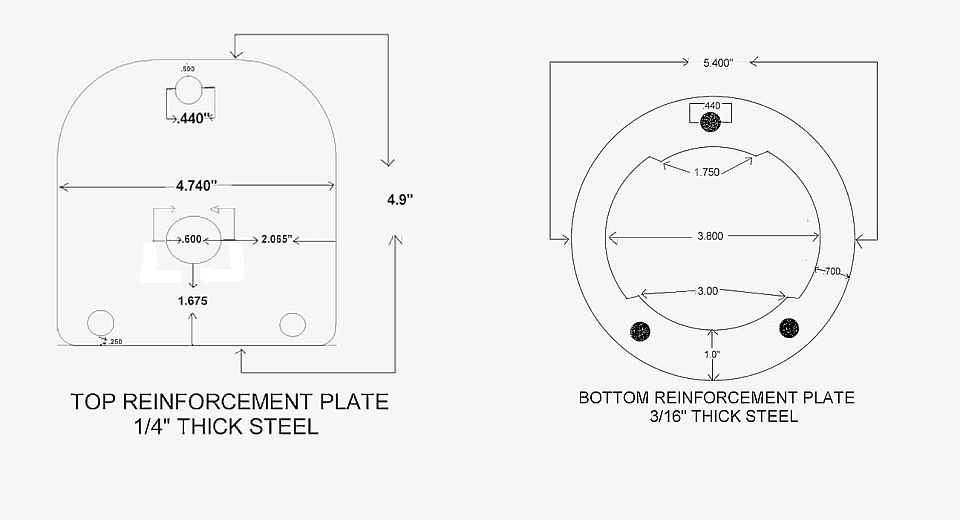

For someone being so concerned about ground clearance due to potholes, real-world road conditions and the like I don't see why you'd approve of those dinky coil over tabs holding up the car. They should go all the way across and have a hole to clear the coilover like the ball joint plate, or at the least should be straight and stout. Look at the old TCP design, that section is as thick as the arms. The ball joint plate welded in shear is not something to be ignored, either.