From SBF Tech.com joel5.0 has the best how-to's

EFI Initial Ignition Timing Calibration and Distributor Installation

This is a question that usually comes up once in awhile, and for the new Ford enthusiast the following procedure will help bumping up that timing and make sure the distributor is installed correctly.

If you have removed the distributor for any type of work, you have to make sure it is installed correctly with #1 cylinder at compression TDC. The following will help you make sure it is installed right.

Tools:

* ½" Combination wrench or the "L" shaped ½" timing wrench

* White Out or liquid paper

* Carburetor cleaner

* Clean rag and/or napkins

* Timing Light

Installing Distributor at #1 Compression:

This is the procedure I always use to make sure #1 cylinder is at compression TDC and not the exhaust cycle or 180° off.

* Remove #1 spark plug.

* Plug the spark plug hole with a piece of rag or a napkin.

* Either have an assistant short click the starter, or use a remote starter switch (a long screwdriver will also work By The Way) to short click the starter solenoid.

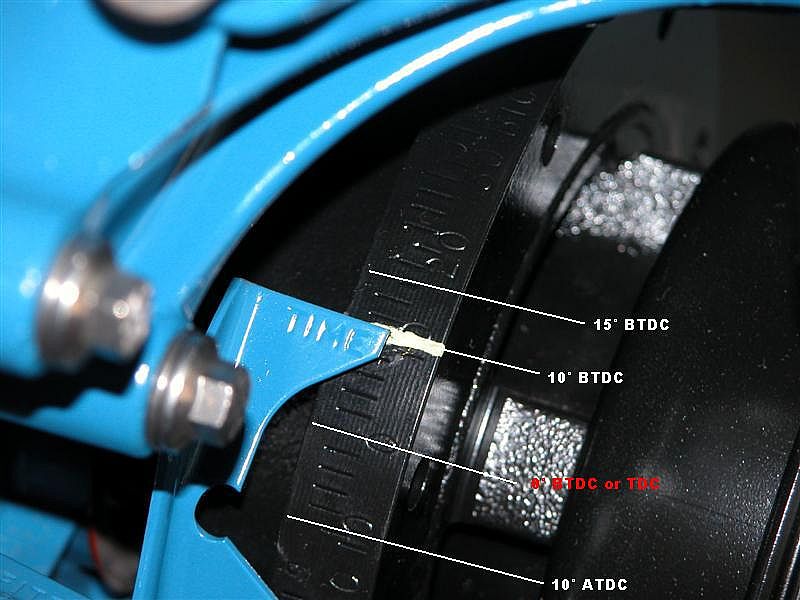

* As soon as the napkin/rag is expelled from the cylinder (sign of compression stroke), rotate the engine by hand using a 15/16" socket and handle for the crankshaft bolt, until the TDC mark is aligned with the timing marker. Even though the 10° BTDC mark shows on the pic, you should use the TDC or 0° mark.

* Now it will be a good time to clean the timing scale on the balancer with some carburetor cleaner and a rag, you should also make the necessary marks with white out or liquid paper, it will make it easier to read when you're setting the initial timing later on.

* Install/Stab distributor noting the orientation of the TFI module connector (if it applies) and the direction of the rotor. You could also use the PIP sensor magnet as a guide, as shown in the 1-tooth-off retarded example below. To correct the condition illustrated by the red line, the distributor would have to be re-indexed using the green line as the reference position point.

* The following pics show how a correctly installed distributor looks like. Notice the position to the LH side of the stator magnet (white dot) of the vanes rotor.

* The spark plug cables should be arranged in the order shown below for a 5.0L HO or 351W, if a regular 302w is the one been worked, simply use the 1-5-4-2-6-3-7-8 firing order instead.

Initial Timing Calibration:

Now you're ready to start the engine and set initial timing.

* Locate the SPOUT connector, '86-93 Mustangs have it in the TFI module harness near the connector, and '94-'95 Mustangs have it near the MAF, at the RH fenderwell as shown below.

'86 - '93 Mustangs

'94-'95 Mustangs

* Remove the SPOUT connector jumper plug and secure it.

* Start the engine and bring it to operating temperature.

* Using the timing light, set initial to the setting you would like to test, rotating the distributor CW will advance timing, and CCW will retard timing. 10° BTDC is the stock setting, but you may want to check if 12° BTDC or 14° BTDC will work for more power.

* Tighten distributor base bolt and confirm setting did not change.

* Reconnect the SPOUT jumper plug into the connector.

* Check timing change with the timing light, the reading should be between 20° - 24° BTDC = sign the computer is controlling spark advance.

* You're done....

NOTE:

In the event you misplace or loose the SPOUT connector plug, a simple jumper wire or clip will work fine. The SPOUT plug is simply a jumper used to allow the ECM to control spark advance, or disconnect the ECM from controlling spark advance; and be able to set initial spark.

Testing for Engine Ping

You may want to verify the new initial setting (if you advanced it to a higher setting) does not cause engine ping. To do so, suggest the following procedure.

* Make sure engine is at operating temperature.

* Find a long straightway for the test.

* Increase speed to 25-35 MPH and shift into 4th gear.

* Increase engine load by pressing accelerator pedal ? down at first, and at WOT making sure you DON'T downshift from 4th. gear.

* Notice if engine ping is heard from the engine, if it is, repeat the Initial Timing Calibration, and retard advance 2° from the current setting.

* Repeat this procedure until engine pinging condition is not noticed.

NOW you're done....Phew

Sounds retarded to me (the timing), but could definitely be some other things mentioned as well. Redo the distributor and try more advance. What happens if you give it throttle?

Sounds retarded to me (the timing), but could definitely be some other things mentioned as well. Redo the distributor and try more advance. What happens if you give it throttle? Sounds retarded to me (the timing), but could definitely be some other things mentioned as well. Redo the distributor and try more advance. What happens if you give it throttle?

Sounds retarded to me (the timing), but could definitely be some other things mentioned as well. Redo the distributor and try more advance. What happens if you give it throttle?