Oh, I also decided to go with a return-style fuel system, so I got a Terminator tank, Fore hat with twin Walbro 255s, and 60 lb injectors. I've already assembled the tank, but I can't assemble the rest of the fuel system until I drop the new engine in. I'll make sure to post those updates, as well.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Flghtmstr1's 700 Rwhp Build

- Thread starter Flghtmstr1

- Start date

-

Sponsors (?)

tank_567

Active Member

Oh, I also decided to go with a return-style fuel system, so I got a Terminator tank, Fore hat with twin Walbro 255s, and 60 lb injectors. I've already assembled the tank, but I can't assemble the rest of the fuel system until I drop the new engine in. I'll make sure to post those updates, as well.

I dont think those 255 are going to do the job, the fuel system is not where you want to cheap out at, please get a set of Ford GT pumps, My brother ran twin Walbro's w/ a return style system and now hes got 3 holes in his block b/c she ran lean...

Mach 1 block, stage 3 patriot heads, Edelbrock intake, stage 2 blower cams, 550rwhp+ hp 12lbs of boost pushing the pumps to the max. Now gone.

Twin 255lbph Walbro's should have easily gotten the job done. Now, if he was trying to push all that fuel through the stock tank feed line...that might have been a problem.

Thanks Tank, but those twin 255s should be sufficient for the amount of power I'll be making. As Gearbanger said, perhaps the rest of your brother's fuel system wasn't up to snuff. Those Walbro 255s are just as good as, if not better than, the Ford GT pumps. I'm using a Fore hat, AN-8 fuel line, Aeromotive 10 micron filter, Fore fuel rails, an F1 regulator, and AN-6 return line, so I'm confident I'll have enough fuel to get the job done. I do thank you for the warning, though, and I'll monitor fuel pressure carefully. If, for some reason, the Walbro 255s aren't enough, I'll drop in two of those new Aeromotive Stealth 340s.

superstang01

Active Member

JymboSlice

Member

- Dec 9, 2008

- 385

- 0

- 17

where are you going to mount your regulator at? I'm trying to find a suitable location for mine.

and to tank.. the return style system with twin walbros are good up to 850 rwhp.....the stock lines are good till about 500 or so i think.

and to tank.. the return style system with twin walbros are good up to 850 rwhp.....the stock lines are good till about 500 or so i think.

where are you going to mount your regulator at? I'm trying to find a suitable location for mine.

I'm not sure yet. I'll probably either mount it directly on the driver's side fuel rail, on the driver's side strut tower, or on the firewall if there's room. I'm going to wait until the new engine is in to see what makes the most sense.

Car is going to be putting down some great numbers once it is finished. I hate build threads since I get excited to see the finished product haha..I know it takes time

I know what you mean; I'll be sure to post updates as soon as they happen. It took a long time for Modular Head Shop to ship my heads (~7 months) so that's why there weren't any updates for so long. Now that everything is in order, I'm confident I'll have it together by the end of the summer.

Update:

Today, I finally had a chance to pull the old engine. I disconnected a zillion wires, removed the power steering pump and A/C compressor (didn't have to disconnect any lines, just moved everything out of the way), attached the engine hoist, and unbolted the engine mounts from the k member:

Tork Tech's bracket really came in handy as a lifting point:

The other end of the chain got attached to one of the transmission bellhousing bolt holes:

Almost free:

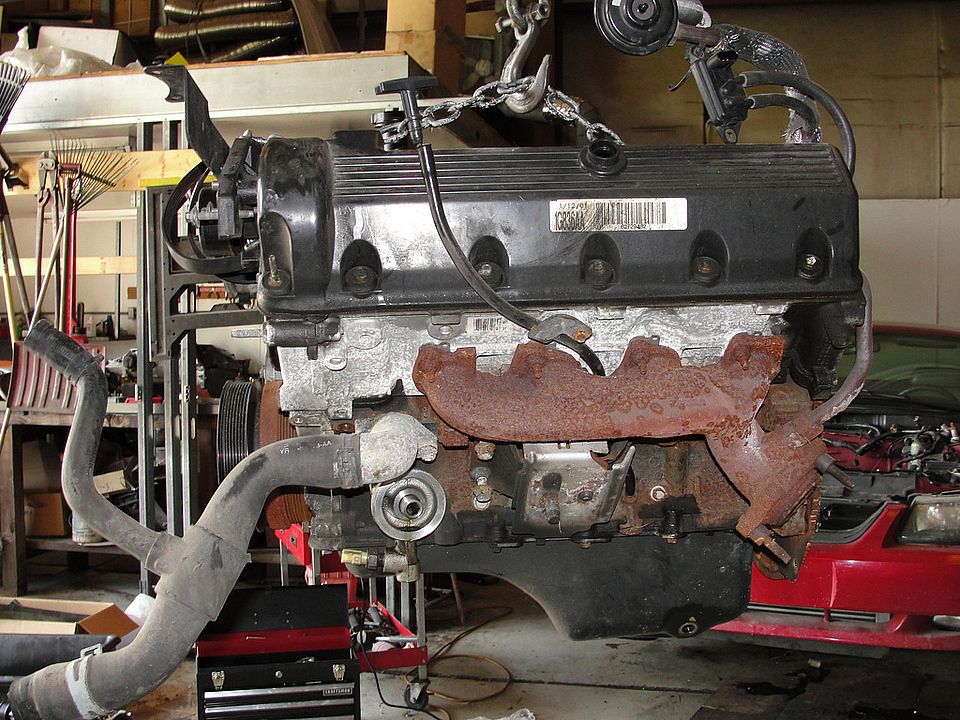

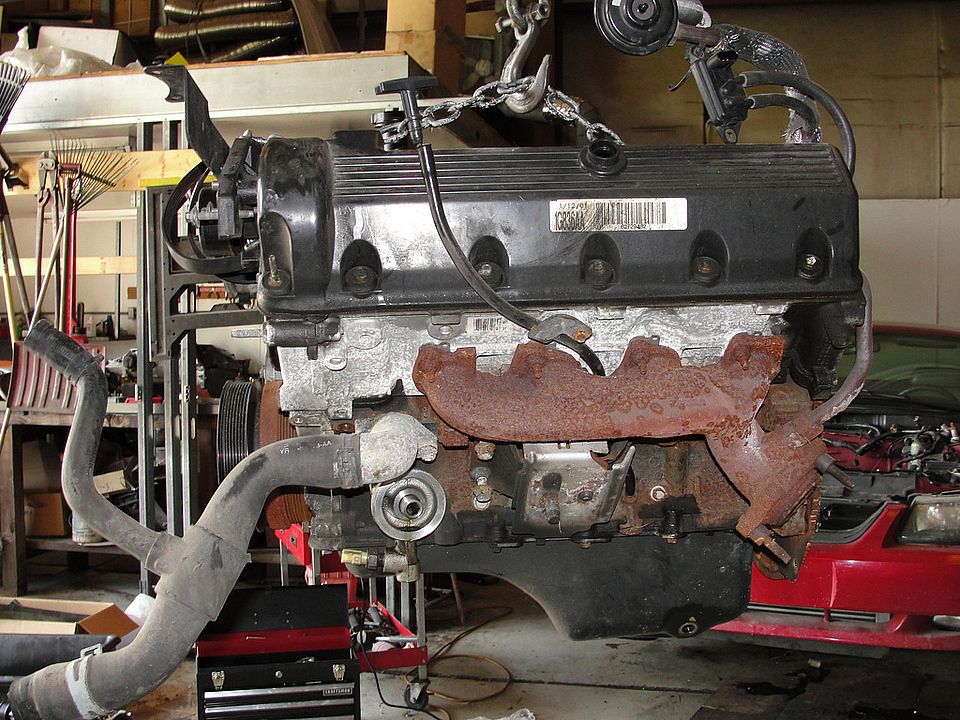

And here it is, dangling precariously above the ground:

Now I know you all know what a 4.6L 2v looks like, but I took these pictures anyway. Anybody want it?

The empty engine bay:

And that's it for now. I'm going to scavenge what I need from the old engine, finish putting the new one together, and drop it in. Ultimately, I'm waiting for Tork Tech to ship me back my re-machined intake manifold and all of the TVS 2300 goodies. I'll update this thread when there's something to report.

Today, I finally had a chance to pull the old engine. I disconnected a zillion wires, removed the power steering pump and A/C compressor (didn't have to disconnect any lines, just moved everything out of the way), attached the engine hoist, and unbolted the engine mounts from the k member:

Tork Tech's bracket really came in handy as a lifting point:

The other end of the chain got attached to one of the transmission bellhousing bolt holes:

Almost free:

And here it is, dangling precariously above the ground:

Now I know you all know what a 4.6L 2v looks like, but I took these pictures anyway. Anybody want it?

The empty engine bay:

And that's it for now. I'm going to scavenge what I need from the old engine, finish putting the new one together, and drop it in. Ultimately, I'm waiting for Tork Tech to ship me back my re-machined intake manifold and all of the TVS 2300 goodies. I'll update this thread when there's something to report.

Hey guys, I thought I'd give you all an update. First and foremost: I got an email from Charles at Tork Tech that my TVS 2300 is shipping out tomorrow (Monday)! He said that they're revamping their web site, and that they intend to offer the TVS 2300 as their top-of-the-line product, so others will be able to duplicate what I'm doing if they're so inclined.

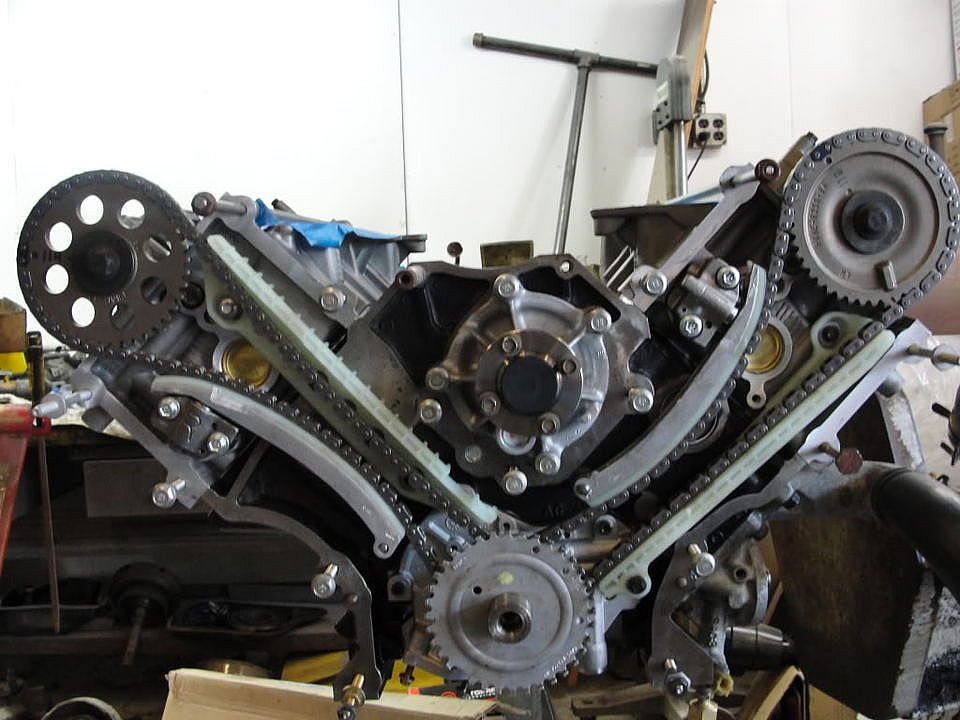

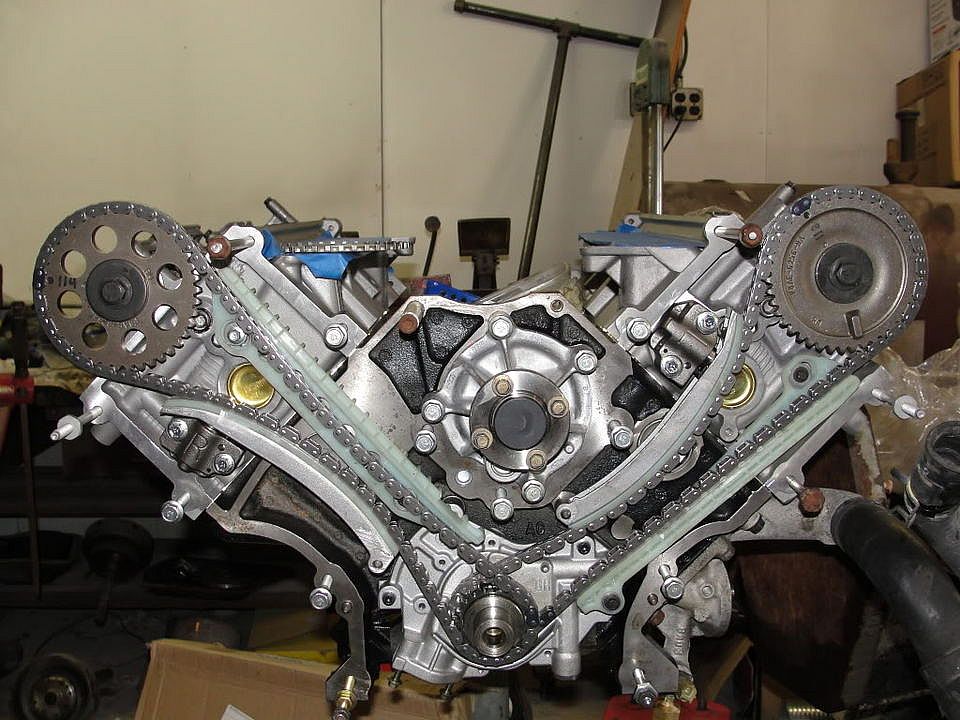

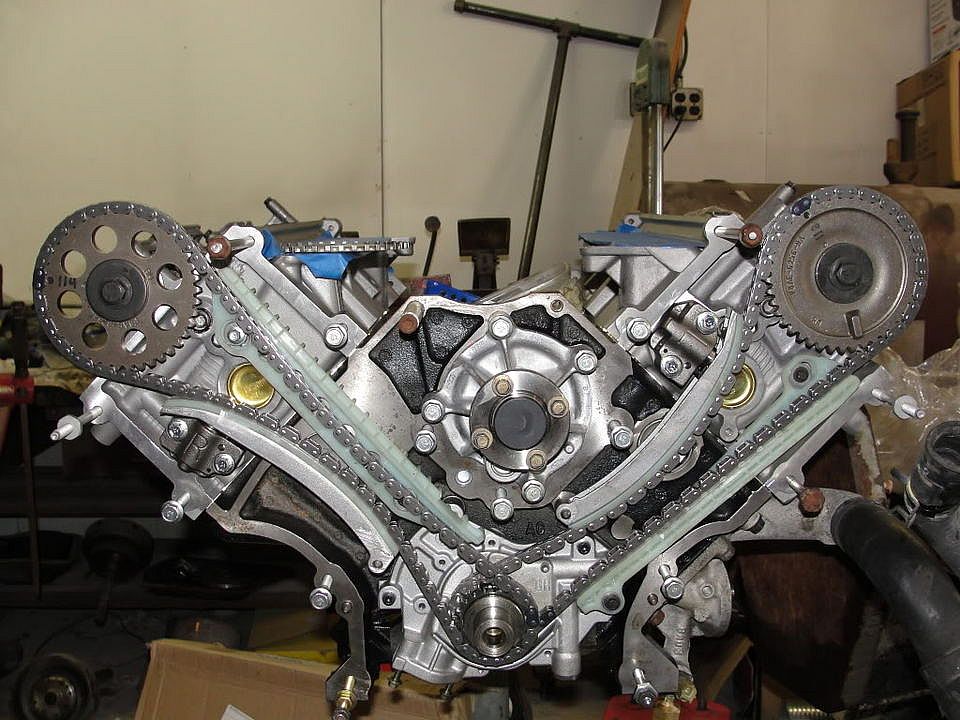

Last week, I attempted to weld the Trick Flow crank sprockets together so I could time the engine and button it up. Alas, my skills with a stick welder are lacking, and the rod itself was much too large to be able to weld cleanly between the sprockets. To make a long story short, I ruined them beyond repair, so I had to buy a new set from Summit (the originals came free with my heads from MHS). Once I received the new set, I took them to a local welder to get it done right. He tried his best with a thin wire MIG, but he wasn't successful either. Fortunately, he didn't ruin the new sprockets, but I needed to find a better solution. Since MHS and Trickflow both warn that the crank keyway can be sheared off if the sprockets aren't secured to each other, and welding seemed to have failed, I decided to attach them with a roll pin. I was avoiding doing so because I knew that the gears were hardened steel and I assumed it would take forever to drill them out. Alas, I was right. Once I finally got them pinned together, I put the rest of the timing stuff together:

Here's the passenger's side cam sprocket:

And here's the driver's side:

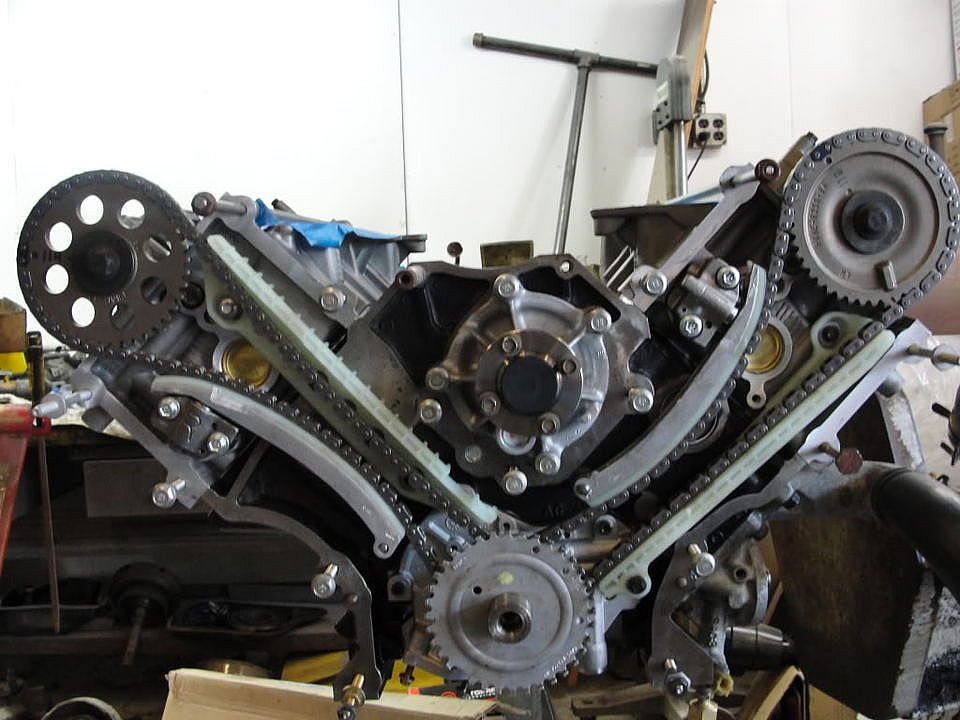

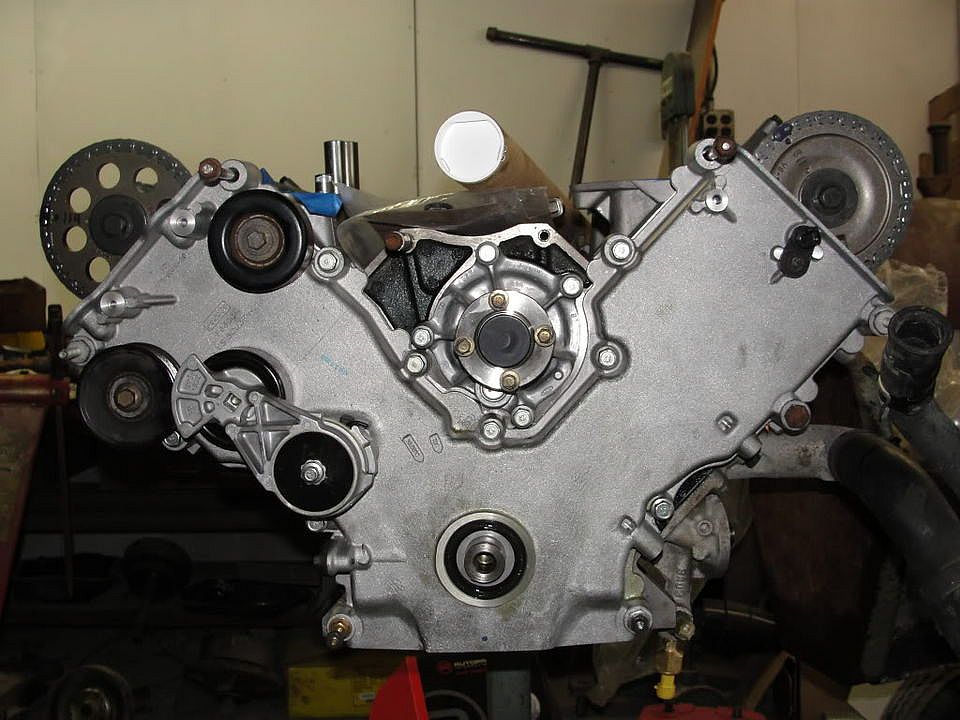

Notice the blue end links. When Nick assembled my heads and cams, he found that the driver's side cam was ground to a 118 centerline, and the passenger's side 114 degrees. Since they were supposed to be on a 110 centerline, I advanced the driver's side 8 degrees and the passenger's side 4 degrees:

Here's the engine fully timed and ready to be finished up:

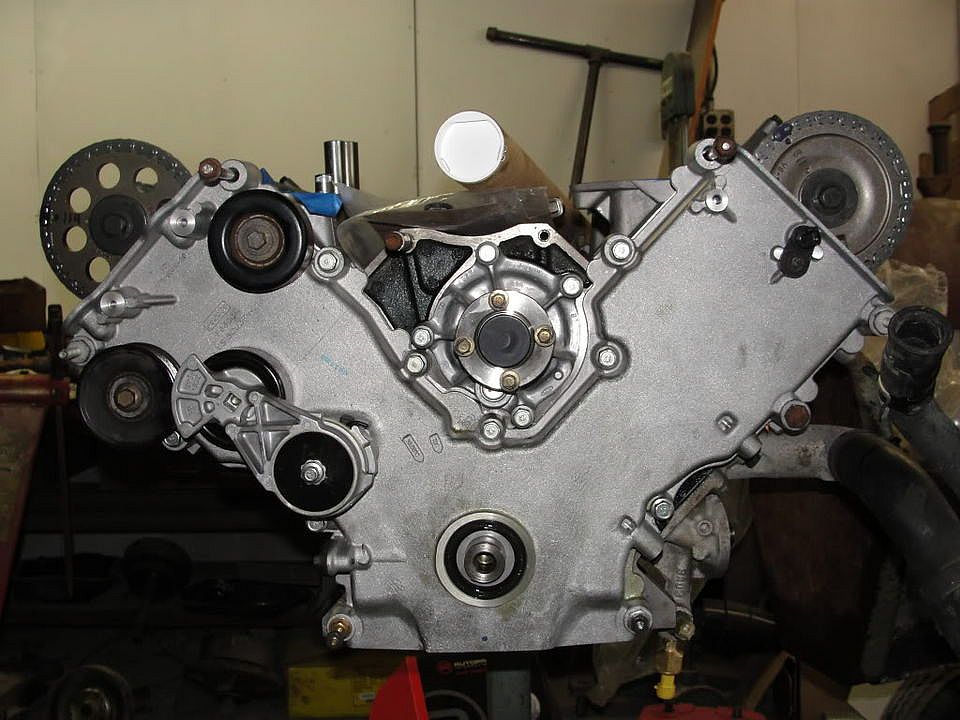

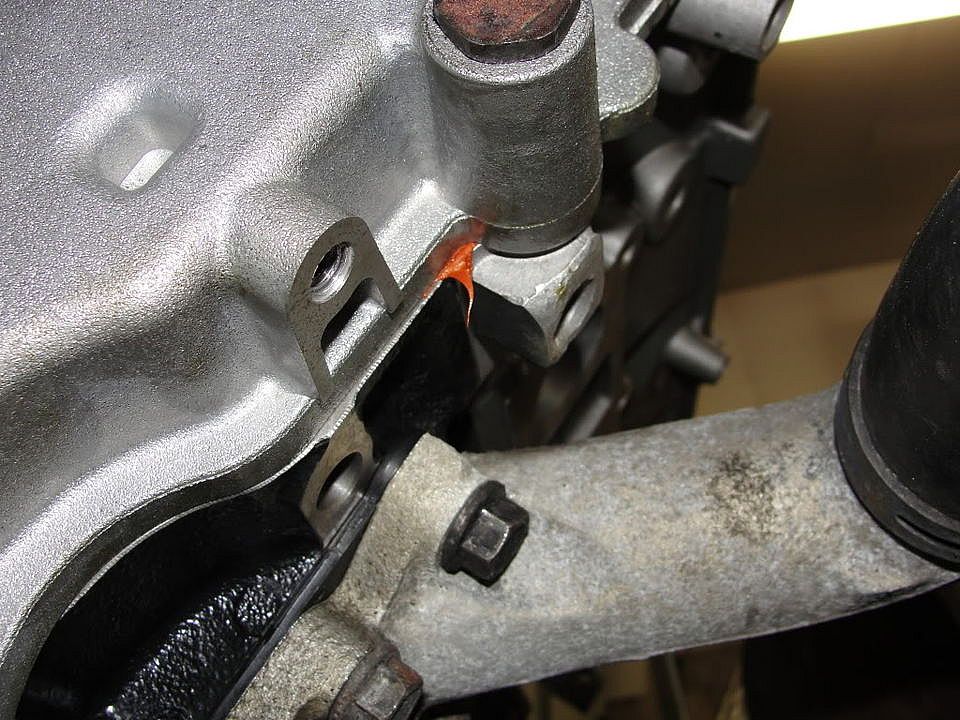

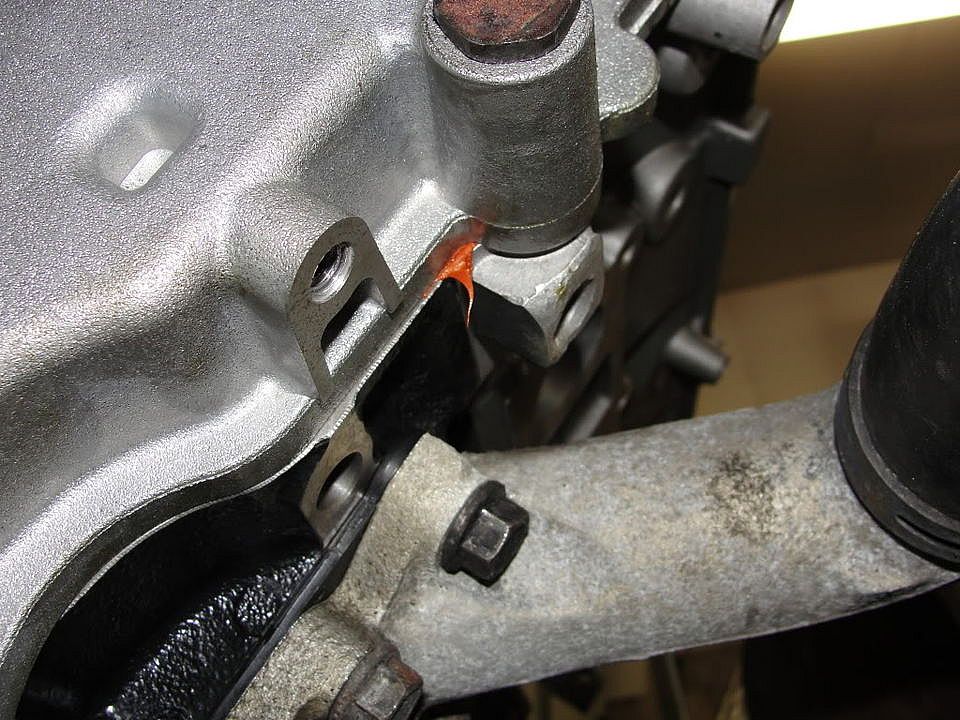

Next, it was time to put the front cover on. I pressed in the new front seal, and put a dab of RTV on the cracks between the heads and block, and on the top of the heads where the valve covers would sit:

Once the front cover was on, I installed the valve covers:

Next, I installed the rear main cover and seal. Unfortunately, I forgot to take pictures of this step, but it wasn't that interesting anyway. I wirebrushed the mating surfaces of the cover (I reused the factory one), drove in the dowels that locate it in the block, pressed in the new rear main seal, ran a bead of RTV around the rear cover, and attached it to the engine using the old bolts. I had to take the engine off the stand for this step. After I was done, I put the engine back on the stand, flipped it upside down, and installed the MMR windage tray, 4v oil sump tube, and MMR oil pan. I also installed new Ford motor mounts. I reused the heat shields from the old ones after cleaning them up with some brake cleaner and a wire wheel. Also, I installed a real oil pressure sender to be used with my Speedhut gauges.

Here's the completed engine (upside down):

Now, all I'm waiting for is the transmission. Once that's done, I'll drop everything in at once, slap the blower on, do the fuel system, and get it tuned. I'll post back again when I have more updates!

Last week, I attempted to weld the Trick Flow crank sprockets together so I could time the engine and button it up. Alas, my skills with a stick welder are lacking, and the rod itself was much too large to be able to weld cleanly between the sprockets. To make a long story short, I ruined them beyond repair, so I had to buy a new set from Summit (the originals came free with my heads from MHS). Once I received the new set, I took them to a local welder to get it done right. He tried his best with a thin wire MIG, but he wasn't successful either. Fortunately, he didn't ruin the new sprockets, but I needed to find a better solution. Since MHS and Trickflow both warn that the crank keyway can be sheared off if the sprockets aren't secured to each other, and welding seemed to have failed, I decided to attach them with a roll pin. I was avoiding doing so because I knew that the gears were hardened steel and I assumed it would take forever to drill them out. Alas, I was right. Once I finally got them pinned together, I put the rest of the timing stuff together:

Here's the passenger's side cam sprocket:

And here's the driver's side:

Notice the blue end links. When Nick assembled my heads and cams, he found that the driver's side cam was ground to a 118 centerline, and the passenger's side 114 degrees. Since they were supposed to be on a 110 centerline, I advanced the driver's side 8 degrees and the passenger's side 4 degrees:

Here's the engine fully timed and ready to be finished up:

Next, it was time to put the front cover on. I pressed in the new front seal, and put a dab of RTV on the cracks between the heads and block, and on the top of the heads where the valve covers would sit:

Once the front cover was on, I installed the valve covers:

Next, I installed the rear main cover and seal. Unfortunately, I forgot to take pictures of this step, but it wasn't that interesting anyway. I wirebrushed the mating surfaces of the cover (I reused the factory one), drove in the dowels that locate it in the block, pressed in the new rear main seal, ran a bead of RTV around the rear cover, and attached it to the engine using the old bolts. I had to take the engine off the stand for this step. After I was done, I put the engine back on the stand, flipped it upside down, and installed the MMR windage tray, 4v oil sump tube, and MMR oil pan. I also installed new Ford motor mounts. I reused the heat shields from the old ones after cleaning them up with some brake cleaner and a wire wheel. Also, I installed a real oil pressure sender to be used with my Speedhut gauges.

Here's the completed engine (upside down):

Now, all I'm waiting for is the transmission. Once that's done, I'll drop everything in at once, slap the blower on, do the fuel system, and get it tuned. I'll post back again when I have more updates!

Looking awesome! 700 to the tires and a built auto will go mid 9's! Should be fun!

I don't know what it will make lol. Nobody has tried a combo like this before, so it's a bit of a crapshoot. I'm shooting for low 10s / high 9s; anything more than that is gravy. More importantly, I intend for this setup to be enjoyable to drive on the street and capable of serving as a daily driver. I might do a low-boost "street" tune and a high-boost "race" setup to achieve this, if I find the full-boost setup is too wild. I don't think many people daily drive 700 rwhp cars, and I'm sure there's a reason for that.

PAN1K

Member

Sounds lilke a lot of fun! Keep the updates coming. Can't wait to see a video of the first trip down the strip!

Full boost setup should be fine. Just keep your foot out of it or modulate the throttle. I dd 700rwhp in a 3100 pound car just fine. Soon to be 850rwhp, with a 6 speed. 700rwhp DD is very common here.

I think a lot will depend on how streetable your auto and cams are. The amount of boost won't have any impact under normal driving.

I think a lot will depend on how streetable your auto and cams are. The amount of boost won't have any impact under normal driving.

trombonedemon

Well-Known Member

Excellent build. I have a 97 that I am adding a TT kit to. Do I need the 99+ timing cover? I heard that I do because of the belt lay out is different and the belt tensioner is in the way on a 97? Cannot wait to see your kit completed

I don't know anything about the timing covers, unfortunately. I have a 2001, so the timing cover is already the "newer" one, and I used that on the new engine as well. I do remember Charles at TT mentioning something about a belt tensioner being in the way, but I never had a problem installing the kit the first time around.

Flight, what internals are you running?

I'm running MMR's 1000S 5.3L stroker shortblock, with a forged Kellog crank, Manley H-beam rods, Manley 28cc dished pistons w/ Teflon coated skirts, and all ARP hardware.

Why do you ask, are you planning something similar?

trombonedemon

Well-Known Member

I don't know anything about the timing covers, unfortunately. I have a 2001, so the timing cover is already the "newer" one, and I used that on the new engine as well. I do remember Charles at TT mentioning something about a belt tensioner being in the way, but I never had a problem installing the kit the first time around.

I'm running MMR's 1000S 5.3L stroker shortblock, with a forged Kellog crank, Manley H-beam rods, Manley 28cc dished pistons w/ Teflon coated skirts, and all ARP hardware.

Why do you ask, are you planning something similar?

Uhhhhh, nope. But that bit of info. is really good for your thread, plus the info is good must in case some-one wants to donate to my wallet fund and I'm getting that rebuild itch.

Just dropped 3500 for a stock rebuild cause of a mistake of mind

, sooooo forged rebuild is out of the question.

, sooooo forged rebuild is out of the question.I'm into hearing people doing really well, kind of makes my day!

Similar threads

- Replies

- 1

- Views

- 175

- Replies

- 2

- Views

- 345

- Replies

- 13

- Views

- 2K

- Replies

- 12

- Views

- 698