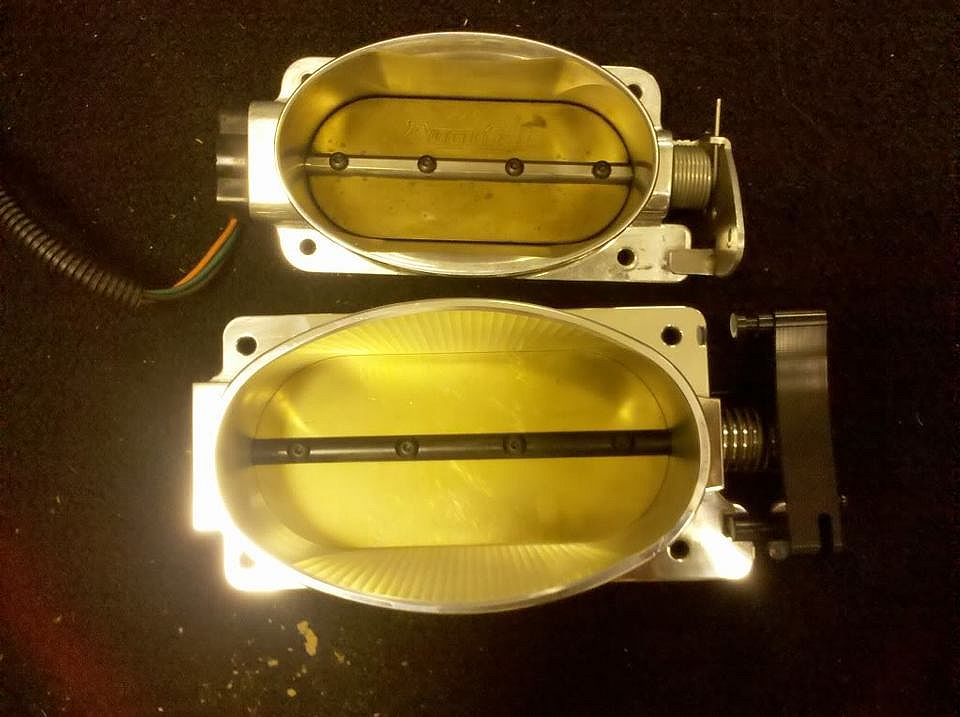

This has been a mind bender for some time and I can't quite talk myself into into if this will work and not create and unmetered air issue. The reason behind moving the bypass location would be to circulate from the cool side of the system staving off the KB heat monster. Look at the picture in scenario one this is how I currently have my bypass setup where the outlet is on the hot side and directs hot air back to the inlet. This circulation is before the meter which I'm not sure maters on a KB closed system???

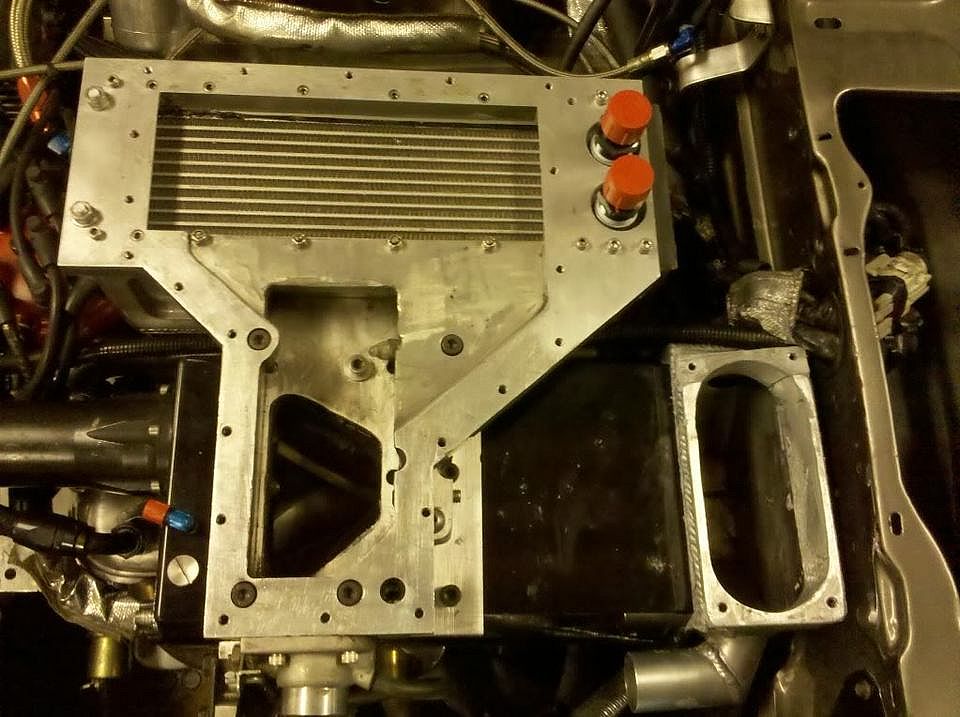

Scenario two below is how I would like to run my byass with the outlet from the cool side circulating back to the inlet. I believe that even though the air is already metered it is still withing the vac loop which is all forward of throttle body and is not lost. Does this seem to make sense or am I seeing this wrong.