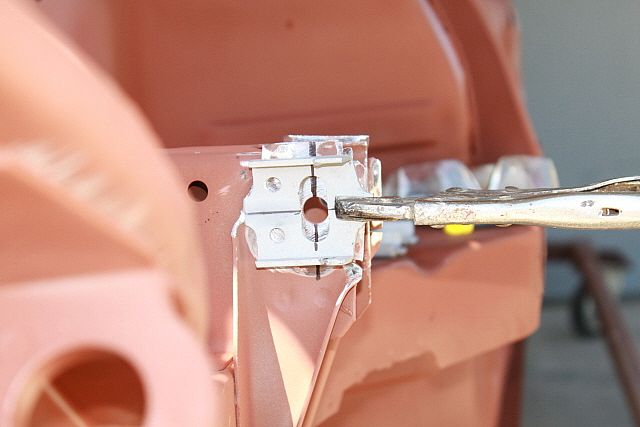

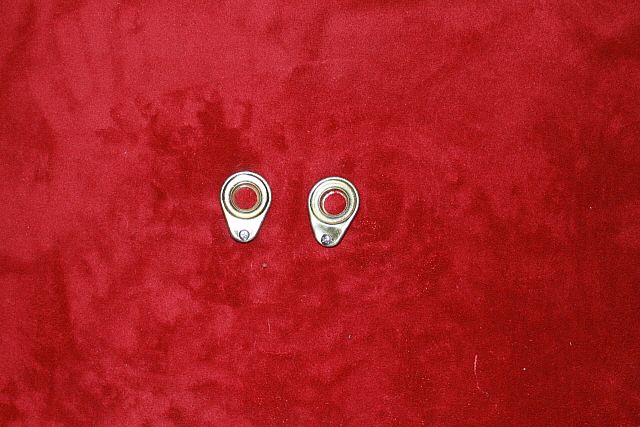

i lowerd the upper a arms ,1 inch down and 1/8 inch back. it requires a little hammering on the inside as well ,just to flatten some flanging around the holes. tomarrow i am going to work on the lower control arm mount. going to make it adjustable using the brackets off an old 68 front end . no more shims to adjust the front end. the radius rods will be changed with modified 67 rods so every thing will now be adjustable. i know ,a kit is available for the lower control mount but uncle Jim aint made of money!

for some reason i find myself typing words backwords,missing keys and hitting wrong keys and not catching it untill its posted. i am learning all by my self and i guess i am doing alright? however,( sence) in horse sence is not spelled incorrect .there was already a horse sense on stangnet and there was already a

for some reason i find myself typing words backwords,missing keys and hitting wrong keys and not catching it untill its posted. i am learning all by my self and i guess i am doing alright? however,( sence) in horse sence is not spelled incorrect .there was already a horse sense on stangnet and there was already a

we got up at 5 in the morning ,drove for an hour one way, and not one ford part there worth looking at. we were looking fore an instrument cluster for a 66 mustang,going to change over to full guage set up.there was enough chevy junk to build 3 chevy motors ,just in the first row. its the same old chevy junk every time we go. not even new junk ,just the same old junk.what happend to all the ford parts?is every one holding on to them or are they gone?

we got up at 5 in the morning ,drove for an hour one way, and not one ford part there worth looking at. we were looking fore an instrument cluster for a 66 mustang,going to change over to full guage set up.there was enough chevy junk to build 3 chevy motors ,just in the first row. its the same old chevy junk every time we go. not even new junk ,just the same old junk.what happend to all the ford parts?is every one holding on to them or are they gone?

I hope work picks back up for you soon and that you don't have to "drop your pants" too often.

I hope work picks back up for you soon and that you don't have to "drop your pants" too often.