You sir did what i ended up not having time for lol and the only thing i despise about my tuck is i can still see loom between the trans tunnel and back of the intake i mean most people wont notice but i do everytime lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Want To Blow 5 Years And $50k On A Foxbody? Step By Step Instructions Inside!

- Thread starter RacEoHolic330

- Start date

-

Sponsors (?)

TrophyHead

15 Year Member

Optima batteries are not a true sealed design. They do have a vent on them. Just do not want you to buy a optima thinking they are sealed.

Keep up the awesome work!

Keep up the awesome work!

Thanks man. Good point about the optima. Spill-proof would have been a more accurate word. That, and the fact that they have glass mat cells that should typically not need to vent under normal charging.

Last edited:

If you go Optima, I prefer the Yellow top deep cycle batteries. My friend uses one and can leave his electric assesories on for hours and never worry about a dead battery. Even the nitrous bottle heater has yet to keep this thing from starting. Wiring is tedious. I remember 3 straight days of just wiring when I did my car and that was everything from scratch!

A yellow top would be great. I found a local deal on a red top that I couldn't pass up though. Wiring is definitely tedious. I'm enjoying it though. The cursing will begin when I heat everything up and nothing works

I bought a nifty TFI relocation kit from McCully racing. The stock TFI location is a known problem on our cars, and the heat from the turbo isn't going to help anything. The kit relocates the TFI outside the engine bay via a shielded harness. It also comes with a modified SN95 heat sink. All you need to do is remove your TFI module, plug in the harness to the three pins on the distributor, and then run the harness to your remotely-mounted TFI. The only thing I didn't like about the kit is the idea of having three spade connectors sticking out of the distributor. It doesn't look right, and I worry about them vibrating loose. I decided to modify the insides of an aftermarket TFI to basically turn it into nothing but a connector.

Here's the unmodified inside

I cut out the pieces that connect the terminals to the board. Somewhat hard to see.

Soldered in jumpers

Nobody will ever know

Here's the whole kit with a Motocraft TFI module. The second picture shows the spade connectors that would have gone directly into the distributor. These will be cut off and spliced into a TFI harness plug. This plug will then plug right into the dummy TFI.

It will look like a normal setup when it's all installed.

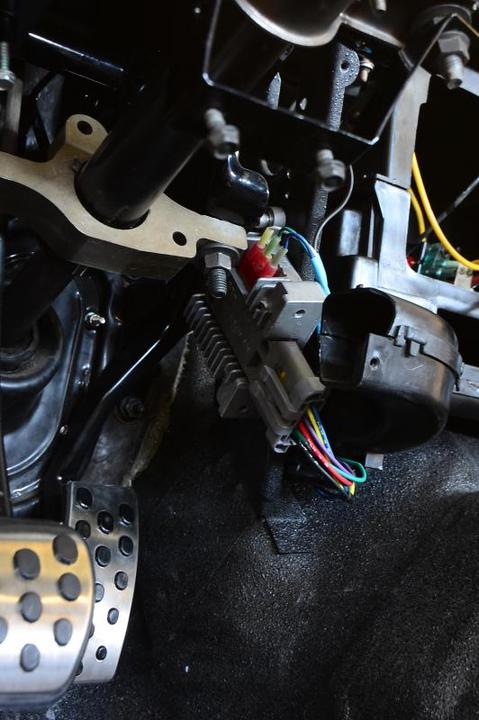

I'm installing the TFI module and heat sink near the throttle pedal. There is a support post for the dash that I bolted it to. That will give me an easy spot to get to it if I ever need to replace it. I can also access the spout connector from there.

I bought a nifty TFI relocation kit from McCully racing. The stock TFI location is a known problem on our cars, and the heat from the turbo isn't going to help anything. The kit relocates the TFI outside the engine bay via a shielded harness. It also comes with a modified SN95 heat sink. All you need to do is remove your TFI module, plug in the harness to the three pins on the distributor, and then run the harness to your remotely-mounted TFI. The only thing I didn't like about the kit is the idea of having three spade connectors sticking out of the distributor. It doesn't look right, and I worry about them vibrating loose. I decided to modify the insides of an aftermarket TFI to basically turn it into nothing but a connector.

Here's the unmodified inside

I cut out the pieces that connect the terminals to the board. Somewhat hard to see.

Soldered in jumpers

Nobody will ever know

Here's the whole kit with a Motocraft TFI module. The second picture shows the spade connectors that would have gone directly into the distributor. These will be cut off and spliced into a TFI harness plug. This plug will then plug right into the dummy TFI.

It will look like a normal setup when it's all installed.

I'm installing the TFI module and heat sink near the throttle pedal. There is a support post for the dash that I bolted it to. That will give me an easy spot to get to it if I ever need to replace it. I can also access the spout connector from there.

Last edited:

The engine is completely wired. I'm in the process of bundling up the harness and getting it into some wire loom. Some wires are too long and need to be trimmed and re-terminated. The only thing that I may need to change is how the fuel pump is wired. The panel only has a 15A fuse, but the Fuelab pump requires a 12GA relayed circuit and a 25A fuse. I have an e-mail into the company that made the panel to get their opinion on how it's best to wire the pump. I'm thinking another relay will be necessary. More pictures will be up tomorrow. Next will be running the feed and ground from the battery to the front of the car.

What are you using to wrap the wires/harness in? Please tell me its NOT that oil magnet convoluted stuff.

The engine is completely wired. I'm in the process of bundling up the harness and getting it into some wire loom. Some wires are too long and need to be trimmed and re-terminated. The only thing that I may need to change is how the fuel pump is wired. The panel only has a 15A fuse, but the Fuelab pump requires a 12GA relayed circuit and a 25A fuse. I have an e-mail into the company that made the panel to get their opinion on how it's best to wire the pump. I'm thinking another relay will be necessary. More pictures will be up tomorrow. Next will be running the feed and ground from the battery to the front of the car.

Isn't the 25 amp fuse, installed in-line of the fuel pump? If so, the relay itself would be the only fused through the panel and it doesn't require much juice at all.

What are you using to wrap the wires/harness in? Please tell me its NOT that oil magnet convoluted stuff.

I'm not using the corrugated plastic split loom, if that's what you're referring to. I'm using a braided mesh loom.

Isn't the 25 amp fuse, installed in-line of the fuel pump? If so, the relay itself would be the only fused through the panel and it doesn't require much juice at all.

The fusing is always done directly off the 12V source feed to the relay, not off the feed wire directly to the pump. Here's the schematic for the Fuelab pump.

What I can do to make this work is use what is now the output to the pump (stock color is pink/black) as the signal wire (blue wire above) to a new 30A relay. I can pull a fused 12V source off the battery and run it to the relay. I believe I need to keep the stock relay one way or another because of the way it's wired into the ECM. Unless the panel manufacturer has a more efficient way to do things, this will work. This is how any aftermarket in-line pump is wired in. The only difference for me is that I won't be powering an in-tank pump as well off the stock relay, so it's a little redundant to have a relay powering a relay.

I'm also going to run a wire from the pump feed up to the dash so I can have a 'pump on' indicator light. The last thing I want is not knowing if I lost voltage to the pump.

Last edited:

Well I read all 57 pgs and I must say your attention to detail is insane. What did you use on the shock towers to protect them from getting tore up from the CC plate adjusting? Cant wait to see this thing done and what your going to do to the interior!!!

Thanks a lot man. The tape on the strut towers is slick tape. It's an Ultra High Molecular Weight Polyethylene tape. Rick at RNH recommended it to use. It's pretty cool stuff.

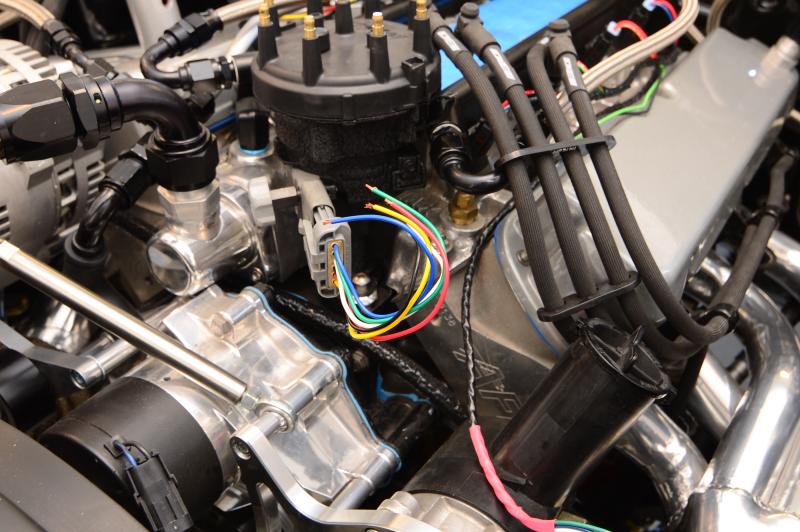

I finished up the modifications to the TFI wiring. Modified the plug and spliced the harness in.

Most of the tape I'm using on the car, especially in the engine bay, is self-fusing silicone tape. I'm using some high quality electrical tape here and there as well, but I like the silicone tape because it doesn't make the wires all sticky if you need to cut the tape off for some reason. Once this stuff is wrapped over itself, it's not going anywhere.

Here's the location where I mounted the TFI.

I managed to start putting the engine bay wires in loom.

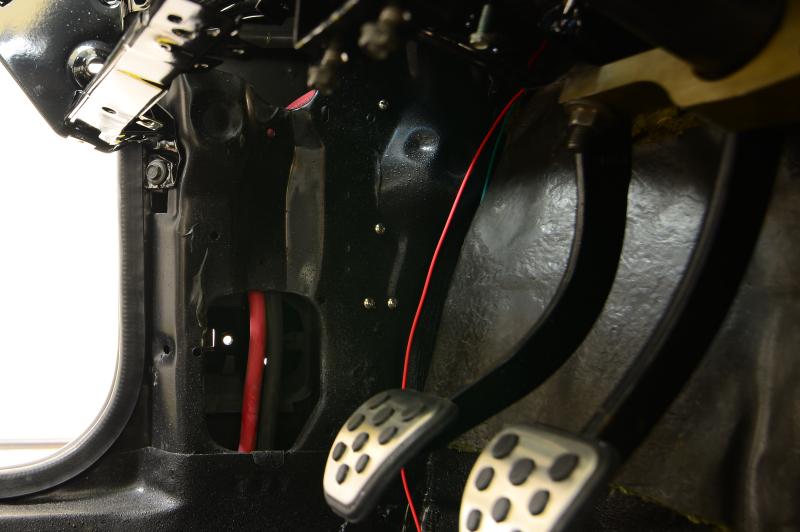

Cleaned up the wiring along the floor. This will all get 1" loom. Somewhat oversized so the wires can lay out a little flatter under the carpet.

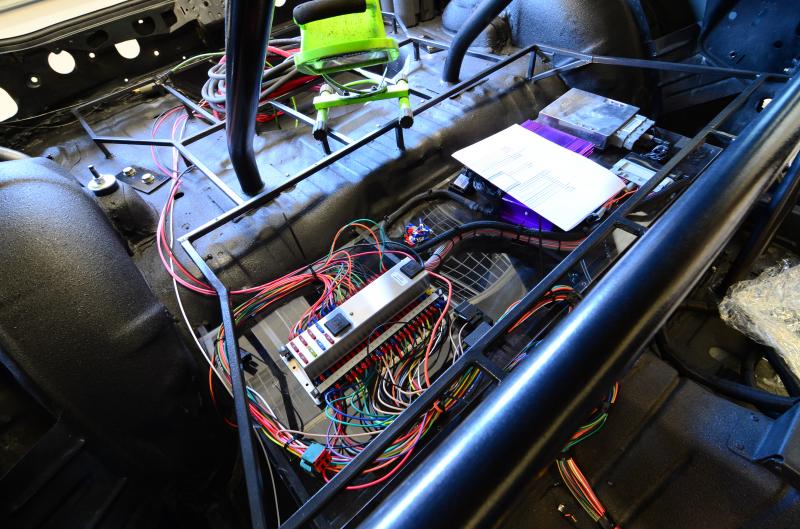

Didn't get a chance to clean up the wires at the panel. Still a mess.

BAP sensor location, as well as the route for the MAF sensor and O2 sensors.

I finished up the modifications to the TFI wiring. Modified the plug and spliced the harness in.

Most of the tape I'm using on the car, especially in the engine bay, is self-fusing silicone tape. I'm using some high quality electrical tape here and there as well, but I like the silicone tape because it doesn't make the wires all sticky if you need to cut the tape off for some reason. Once this stuff is wrapped over itself, it's not going anywhere.

Here's the location where I mounted the TFI.

I managed to start putting the engine bay wires in loom.

Cleaned up the wiring along the floor. This will all get 1" loom. Somewhat oversized so the wires can lay out a little flatter under the carpet.

Didn't get a chance to clean up the wires at the panel. Still a mess.

BAP sensor location, as well as the route for the MAF sensor and O2 sensors.

The fusing is always done directly off the 12V source feed to the relay, not off the feed wire directly to the pump. Here's the schematic for the Fuelab pump.

What I can do to make this work is use what is now the output to the pump (stock color is pink/black) as the signal wire (blue wire above) to a new 30A relay. I can pull a fused 12V source off the battery and run it to the relay. I believe I need to keep the stock relay one way or another because of the way it's wired into the ECM. Unless the panel manufacturer has a more efficient way to do things, this will work. This is how any aftermarket in-line pump is wired in. The only difference for me is that I won't be powering an in-tank pump as well off the stock relay, so it's a little redundant to have a relay powering a relay.

I'm also going to run a wire from the pump feed up to the dash so I can have a 'pump on' indicator light. The last thing I want is not knowing if I lost voltage to the pump.

Kill two birds with one stone and put a circuit breaker in the dash instead of using a fuse through the panel:

http://www.partman.com/boat-systems...rs/breaker-30-amp-push-button-reset-only.html

Who wants a light staring them in the face when the pump is working correctly?

Got the Mcleod hydraulic clutch kit installed. Everything went in pretty easily. It took a bit of time to get the whole thing bled, but I eventually got good pedal feel. It definitely makes the Spec stage 3 feel a little bit easier on the leg.

I also cleaned up the wiring around the panel. Looks a little nicer now.

I have all this wiring done, but no power yet. Decided now is a good time to get the battery cables routed so I can start testing voltage on everything I'm installing. I wanted to route the cables away from everything so I drilled some holes and fished the cables through the rockers . Out of sight and out of mind.

I'm going to bolt an insulated post above the line lock solenoid. The battery cable will terminate there and then I can use that post to distribute power to the rest of the car. The ground cable will go to the block and a bolt I welded to the frame rail. Still LOTS more wiring to look forward to.

I also cleaned up the wiring around the panel. Looks a little nicer now.

I have all this wiring done, but no power yet. Decided now is a good time to get the battery cables routed so I can start testing voltage on everything I'm installing. I wanted to route the cables away from everything so I drilled some holes and fished the cables through the rockers . Out of sight and out of mind.

I'm going to bolt an insulated post above the line lock solenoid. The battery cable will terminate there and then I can use that post to distribute power to the rest of the car. The ground cable will go to the block and a bolt I welded to the frame rail. Still LOTS more wiring to look forward to.

In case I haven't sucked up enough, I just want to say that it's your car, (and it's build ethic) that I will emulate this time with mine. Running that big assed -0 gauge through the rocker is another one of those "why didn't I think of that" kind of things. Thanks for giving me another idea to steal.

One question though,........what keeps you from running a rocker molding screw right into that cable?

One question though,........what keeps you from running a rocker molding screw right into that cable?

Last edited:

Thanks Mike. Suck up all you want! And the battery cables are #1/0, for the record

I actually didn't even think about the molding screws, but that rocker channel is so deep that the screws won't come anywhere near the cable. The cables are laying on the bottom of the rocker, and there is probably 3" of clearance to the top. I'll double check the screws when I attach that molding to make sure they aren't excessively long anyway.

I had thought about running all the ECU wires through the passenger side rocker, but the idea of fishing 50 wires (one at a time) through that small space was not very appealing to me. The harness will flatten out under the carpet anyway.

I actually didn't even think about the molding screws, but that rocker channel is so deep that the screws won't come anywhere near the cable. The cables are laying on the bottom of the rocker, and there is probably 3" of clearance to the top. I'll double check the screws when I attach that molding to make sure they aren't excessively long anyway.

I had thought about running all the ECU wires through the passenger side rocker, but the idea of fishing 50 wires (one at a time) through that small space was not very appealing to me. The harness will flatten out under the carpet anyway.

I have always Always ALWAYS wanted to checkout that hydro clutch setup.

Curse youz!

Adopt me?

Curse youz!

Adopt me?

I got one word for you..............Thanks Mike. Suck up all you want! And the battery cables are #1/0, for the record

I actually didn't even think about the molding screws, but that rocker channel is so deep that the screws won't come anywhere near the cable. The cables are laying on the bottom of the rocker, and there is probably 3" of clearance to the top. I'll double check the screws when I attach that molding to make sure they aren't excessively long anyway.

I had thought about running all the ECU wires through the passenger side rocker, but the idea of fishing 50 wires (one at a time) through that small space was not very appealing to me. The harness will flatten out under the carpet anyway.

JJJJJTTTTTTT!!!!!!

Similar threads

- Replies

- 32

- Views

- 40K

Progress Thread

'67 Mustang 351C > C4 trans > Clueless 21 year old

- Replies

- 5

- Views

- 2K

- Replies

- 3

- Views

- 10K

- Replies

- 1

- Views

- 7K

- Replies

- 2

- Views

- 3K