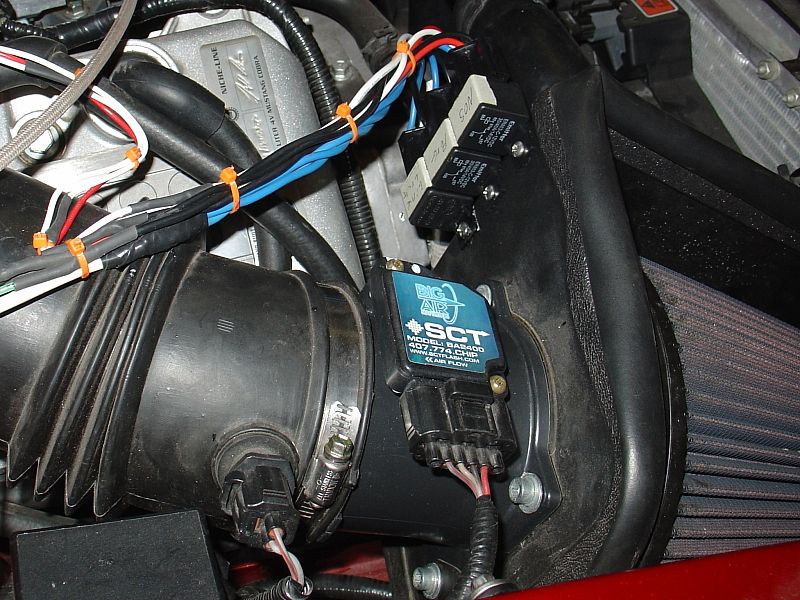

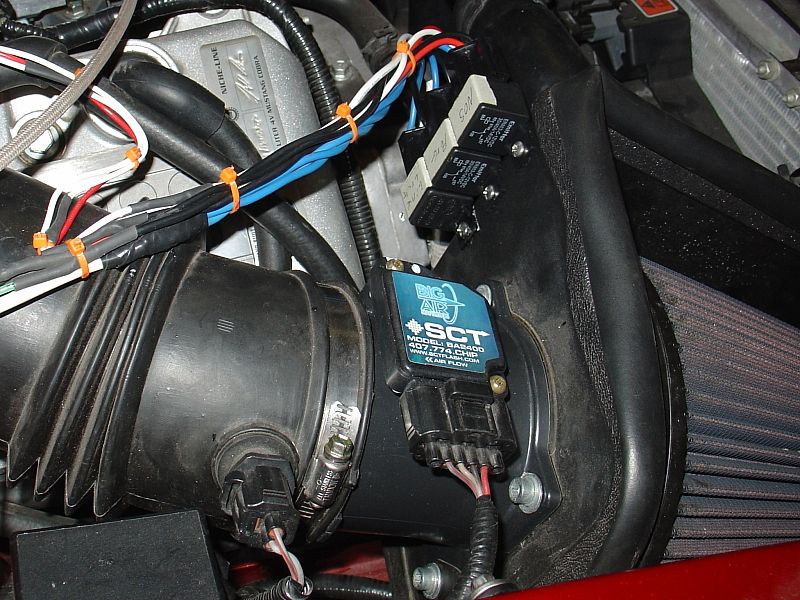

I had to fire up the SCT software for the first time in over a year and grab SCT base files for the Big Air 2400 MAF and the siemens 60lbers and figure out which end of the flasher I was supposed to use but somehow I loaded a tune for the new setup and the crossed my fingers.

Managed to find a milk carton to sit on, slide my foot by the still dangling wires for the radio delete gauges to press in the clutch. Dash gauges and bezel pods lit up, Stock boost gauge overlay to 16 lbs is all I will ever need with my whimpy setup, and it looks stock.

Not only did Lou at Laurel Mt. Mustang give me a good deal on the corner pod bezel, like he always does but he also painted the sucker to a PERFECT match. Thanks Lou! Unbelievable!

Yup, I had to cycle the FP 4 or 5 times, the tank was out of the car 3 times since it started last (but the gas gauge works again SOB!) and I don't have a pprv anymore but after stumbling a bit and one short stab to fill the rails the beast came alive and ran scary smooth.

Black smoke, yeah but it ran. New relayed wiring to the pumps, new black braided garden hose unkinked fuel super highway, 30 micron filter, PPRV trashed and upgraded submersible line, CPR rails with braided equalizer, modded FPDM, BAP on hyperdrive, 60lbers and a BA2400 all with the manners, at least from the first listen, of the stock parts they replaced.

No pipes on it right now, waiting on DSS driveshaft lengthening and the anti-roll setup to chop up that beautiful StainlessWorks 3" exhaust to convert from IRS to over the axle so it is not time to finish tuning it but I really needed hear it run for the first time in 6 mos and straight headers was 100% tool time and therapeutic to the soul.. urg urg

Snapped a couple more pics, wiring is still on top until it is complete and then we will tuck it in with loam covering everything.

Here is where the window switch is for easy track access, no glove box for me, not interested in stealth or showcar neatness, I want utility.

Needed a NOS arming WOT switch.

Here is how the Plenum jet installed, nice and neat, easy to change jets!

Here is the relay block for under the hood, everything added is relay triggered, once again a little overkill, but not required. The IC pump is now manually controlled with a dash switch thru a relay.

Here is mjchip’s upgraded FPDM and the solder splices.

These relays control the BAP and the bottle temp control system.

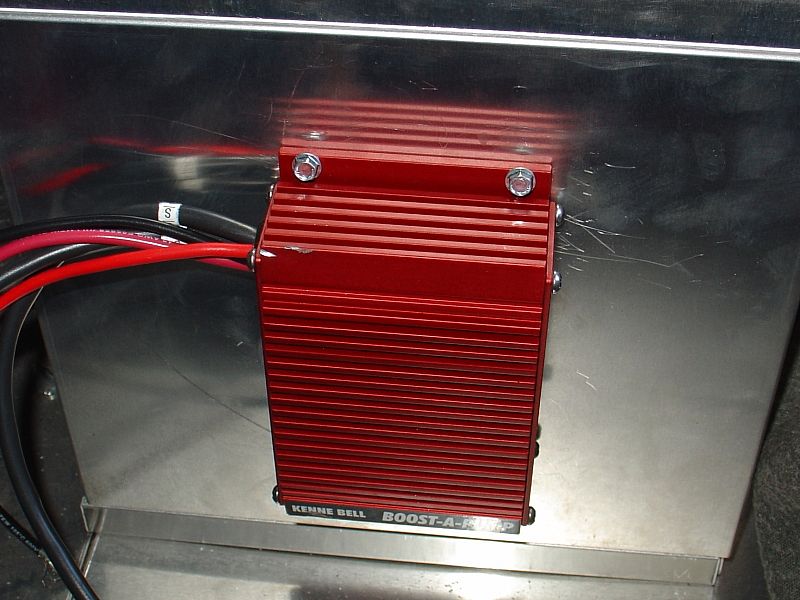

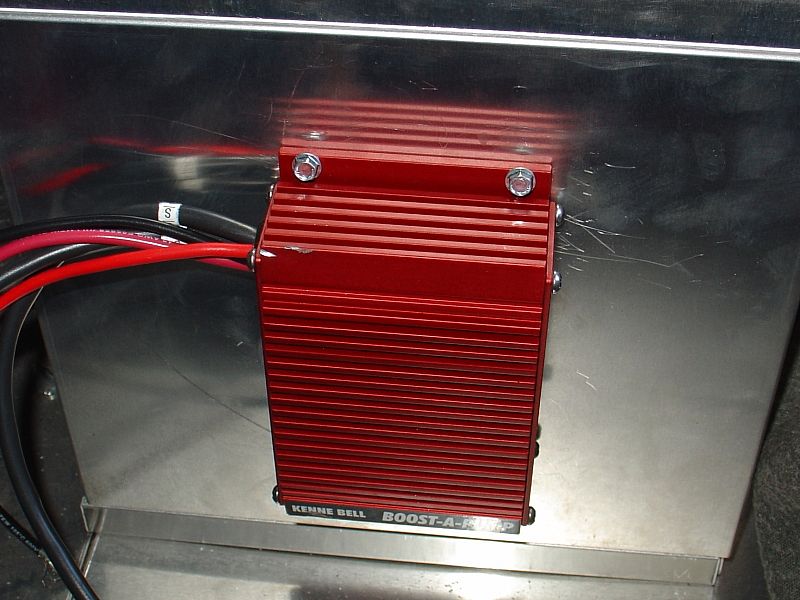

This is where I mounted the BAP, this is a bit older pic, the Hobbs and boost sensor wires have been snipped and jumpered.

Since power is drawn from the back to shorten wire runs, needed a fuse block!

So much for wintertime fun, back to the salt mines...

Managed to find a milk carton to sit on, slide my foot by the still dangling wires for the radio delete gauges to press in the clutch. Dash gauges and bezel pods lit up, Stock boost gauge overlay to 16 lbs is all I will ever need with my whimpy setup, and it looks stock.

Not only did Lou at Laurel Mt. Mustang give me a good deal on the corner pod bezel, like he always does but he also painted the sucker to a PERFECT match. Thanks Lou! Unbelievable!

Yup, I had to cycle the FP 4 or 5 times, the tank was out of the car 3 times since it started last (but the gas gauge works again SOB!) and I don't have a pprv anymore but after stumbling a bit and one short stab to fill the rails the beast came alive and ran scary smooth.

Black smoke, yeah but it ran. New relayed wiring to the pumps, new black braided garden hose unkinked fuel super highway, 30 micron filter, PPRV trashed and upgraded submersible line, CPR rails with braided equalizer, modded FPDM, BAP on hyperdrive, 60lbers and a BA2400 all with the manners, at least from the first listen, of the stock parts they replaced.

No pipes on it right now, waiting on DSS driveshaft lengthening and the anti-roll setup to chop up that beautiful StainlessWorks 3" exhaust to convert from IRS to over the axle so it is not time to finish tuning it but I really needed hear it run for the first time in 6 mos and straight headers was 100% tool time and therapeutic to the soul.. urg urg

Snapped a couple more pics, wiring is still on top until it is complete and then we will tuck it in with loam covering everything.

Here is where the window switch is for easy track access, no glove box for me, not interested in stealth or showcar neatness, I want utility.

Needed a NOS arming WOT switch.

Here is how the Plenum jet installed, nice and neat, easy to change jets!

Here is the relay block for under the hood, everything added is relay triggered, once again a little overkill, but not required. The IC pump is now manually controlled with a dash switch thru a relay.

Here is mjchip’s upgraded FPDM and the solder splices.

These relays control the BAP and the bottle temp control system.

This is where I mounted the BAP, this is a bit older pic, the Hobbs and boost sensor wires have been snipped and jumpered.

Since power is drawn from the back to shorten wire runs, needed a fuse block!

So much for wintertime fun, back to the salt mines...

Attachments

-

2007-0131_snake-dashpods-800.jpg315.8 KB · Views: 85

2007-0131_snake-dashpods-800.jpg315.8 KB · Views: 85 -

2007-0131_snake-NXwindow-800.jpg367.9 KB · Views: 89

2007-0131_snake-NXwindow-800.jpg367.9 KB · Views: 89 -

2007-0131_snake-WOTswitch-800.jpg420.8 KB · Views: 106

2007-0131_snake-WOTswitch-800.jpg420.8 KB · Views: 106 -

2007-0131_snake-jet-800.jpg414.3 KB · Views: 77

2007-0131_snake-jet-800.jpg414.3 KB · Views: 77 -

2007-0131_snake-relays-800.jpg420.5 KB · Views: 95

2007-0131_snake-relays-800.jpg420.5 KB · Views: 95 -

2007-0131_snake-FPDM-800.jpg400.6 KB · Views: 93

2007-0131_snake-FPDM-800.jpg400.6 KB · Views: 93 -

2007-0131_snake-BOXrelays-800.jpg388 KB · Views: 91

2007-0131_snake-BOXrelays-800.jpg388 KB · Views: 91 -

2006-0807-cobra-BAP-800.jpg331.8 KB · Views: 84

2006-0807-cobra-BAP-800.jpg331.8 KB · Views: 84 -

2007-0131_snake-fuseblock-800.jpg380.6 KB · Views: 85

2007-0131_snake-fuseblock-800.jpg380.6 KB · Views: 85

I'm just suprised that the stock pumps are capable of providing enough fuel. I understand the larger diameter fuel lines allow for less restriction in the fuel flow, and the beefier wiring delivers more amperage to the pumps. Just amazes me that the stock pumps can be driven hard enough to supply the thirst a 700HP twin screw demands!

I'm just suprised that the stock pumps are capable of providing enough fuel. I understand the larger diameter fuel lines allow for less restriction in the fuel flow, and the beefier wiring delivers more amperage to the pumps. Just amazes me that the stock pumps can be driven hard enough to supply the thirst a 700HP twin screw demands!