You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New TCP Catalog/Products

- Thread starter hivewax

- Start date

-

Sponsors (?)

Route666

Active Member

Route666

Active Member

i just got their new catalog in the mail... much better than their previous catalogs. lots of new stuff. and, i'm kind of bummed out that my TCP LCA's don't have the new pivot socket and grease-zerk fitting. anyone else get that feeling when buying performance parts?

Good thing you're not into computers and gaming! You upgrade your PC and it will already have been superseded.

Also TCP have hood pins and door latches! Looks like they're really expanding their product range.

gsxrken

Member

Yes, I just received one too. I was careful- I don't think any drool actually made it on to the pages themselves. The catalog is very well done and they do appear to be adding some top-quality items to their lineup... Wilwood, Strange, Ring Brothers hinges and those hood pins. Clever.

ChadiMac22

New Member

- Nov 11, 2007

- 2

- 0

- 0

Yes, I was glad to see that they expanded their product line but very disappointed in the price increases. Specifically, their manual rack and pinion saw a $200 price jump from $1200 to $1400.

Additionally, their front coilover system increased by nearly $300 ($2200 to $2485). Granted, they are now selling this unit with double adjustable shocks, the extra $300 still bums me out.

At first, I was definitely going to use all TCP products from bumper to bumper, but all that may be changing. TCP's price increase have caused me to be a bit more open minded when designing my suspension. I must say, in spite of the price increases, they offer an outstanding product line.

Just my .02

Additionally, their front coilover system increased by nearly $300 ($2200 to $2485). Granted, they are now selling this unit with double adjustable shocks, the extra $300 still bums me out.

At first, I was definitely going to use all TCP products from bumper to bumper, but all that may be changing. TCP's price increase have caused me to be a bit more open minded when designing my suspension. I must say, in spite of the price increases, they offer an outstanding product line.

Just my .02

freddiecougar

New Member

- Nov 28, 2007

- 50

- 0

- 0

I understand that price increases come as a shock, but we really had no choice. Material costs have skyrocketed, as have nearly every cost associated with manufacturing, from labor, to maintenance, etc. There has not been a TCP price increase for a LOOOOONG time, but it had to happen. We manufacture nearly everything in-house, (with the obvious exceptions of WW, Strange, etc.) so the cost increases hit us directly, there is no way to "filter" them out.

If you look at our systems in comparison to the others, apples for apples, our pricing is right in line.

As for the new catalog, Lino did an outstanding job. It is much easier to use, and does a better job of explaining everything we have, and what it does.

Tim

If you look at our systems in comparison to the others, apples for apples, our pricing is right in line.

As for the new catalog, Lino did an outstanding job. It is much easier to use, and does a better job of explaining everything we have, and what it does.

Tim

Yes, I was glad to see that they expanded their product line but very disappointed in the price increases. Specifically, their manual rack and pinion saw a $200 price jump from $1200 to $1400.

Additionally, their front coilover system increased by nearly $300 ($2200 to $2485). Granted, they are now selling this unit with double adjustable shocks, the extra $300 still bums me out.

At first, I was definitely going to use all TCP products from bumper to bumper, but all that may be changing. TCP's price increase have caused me to be a bit more open minded when designing my suspension. I must say, in spite of the price increases, they offer an outstanding product line.

Just my .02

mrmustangman357

Member

- Feb 11, 2007

- 763

- 3

- 18

maybe you should subcontract some of your machining work. having other shops build to your prints saves alot of cost and would make you more competitive

Psydwaze

Founding Member

With all due respect, we ARE the outsourced machine shop. Aside from castings and forgings there isn't too much that we can't manufacture in house.

http://www.cachassisworks.com/cac_tour_1.html

Our shop tour really needs to be updated, because we actually have a lot more equipment than what is shown in the pictures.

This is an example of one of our pallatech machine fixture loading systems. It's a dual-level, 12-fixture, elevator and track loading system that can accommodate 48 individual fixture faces. This particular one handles fixtures for our largest horizontal machining center, which holds about 140 tools.

We also have a variety of fully automated machining centers, laser cutting machines, press brakes, robotic welders, tubing benders, etc.

http://www.cachassisworks.com/cac_tour_1.html

Our shop tour really needs to be updated, because we actually have a lot more equipment than what is shown in the pictures.

This is an example of one of our pallatech machine fixture loading systems. It's a dual-level, 12-fixture, elevator and track loading system that can accommodate 48 individual fixture faces. This particular one handles fixtures for our largest horizontal machining center, which holds about 140 tools.

We also have a variety of fully automated machining centers, laser cutting machines, press brakes, robotic welders, tubing benders, etc.

Route666

Active Member

For what's in the components (materials, processing, and engineering) they're pretty reasonably priced in my opinion. These aren't standard replacement parts. I guess a lot of price misconception comes from not knowing the full depth of any process. As a programmer for a laser cutter, and delving into 3d work and machining as well, I can see where expense comes into these components.

I priced up 20k for all new brakes, steering, suspension, diff, etc. Basically everything between the wheels and the body of the car, everything between the front wheels and your steering wheel and everything between the rear wheels and the driveshaft plus subframes, engine bay bracing and misc hood hinges, pins, etc. To me, for the application, that's a fairly good deal. Expensive, yes, but worthwhile for what you get.

I priced up 20k for all new brakes, steering, suspension, diff, etc. Basically everything between the wheels and the body of the car, everything between the front wheels and your steering wheel and everything between the rear wheels and the driveshaft plus subframes, engine bay bracing and misc hood hinges, pins, etc. To me, for the application, that's a fairly good deal. Expensive, yes, but worthwhile for what you get.

Route666

Active Member

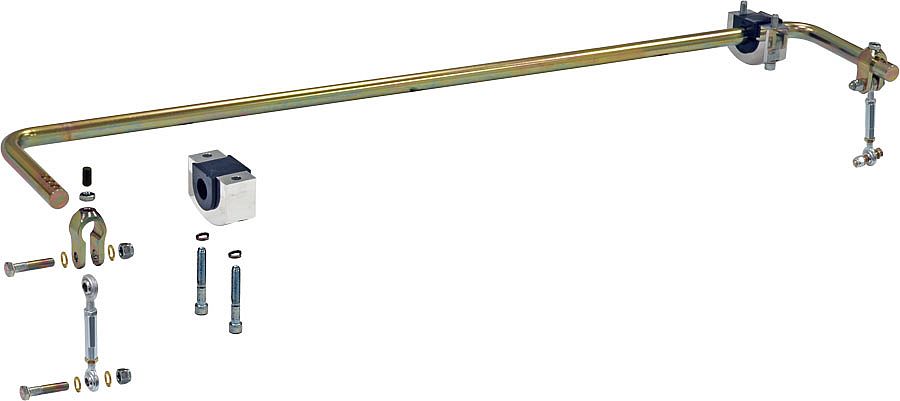

Oh and Lino - I like the incorporation of the Shelby drop into the upper arm mount - makes me wonder why it hasn't been done earlier. Also - are you going to develop a rear sway bar for the rear pushrod suspension system. I heard a while back one was in the making but still nothing.

mrmustangman357

Member

- Feb 11, 2007

- 763

- 3

- 18

because that billet barstock is expensive material, especially done on a cnc mill

I saw the tcp upper control arms with two heim joints. I don't like that design because when you lengthen one side, it would bind

I saw the tcp upper control arms with two heim joints. I don't like that design because when you lengthen one side, it would bind

I don't know what that is but I want it.This is an example of one of our pallatech machine fixture loading systems. It's a dual-level, 12-fixture, elevator and track loading system that can accommodate 48 individual fixture faces. This particular one handles fixtures for our largest horizontal machining center, which holds about 140 tools.

Psydwaze

Founding Member

... are you going to develop a rear sway bar for the rear pushrod suspension system...

We've been extremely busy with multiple projects in each of the three product lines, so the rear pushrod anti-roll bar hasn't exactly been a front-burner item. However, it is on our to do list. I'm pushing for something similar to the sliding-link adjustable anti-roll bar we have for the g-Bar system. Since we already make usable or similar components, it should cut down on our time to get it into production once we get started.

Attachments

Route666

Active Member

We've been extremely busy with multiple projects in each of the three product lines, so the rear pushrod anti-roll bar hasn't exactly been a front-burner item. However, it is on our to do list. I'm pushing for something similar to the sliding-link adjustable anti-roll bar we have for the g-Bar system. Since we already make usable or similar components, it should cut down on our time to get it into production once we get started.

Ok Cool, thanks.

One more question - with the coilover setup (looking at the front) what reason do the coilovers have to be mounted the way they are? I don't know much about shocks, so maybe it is something to do with valving, or stopping debris getting to the piston rod, or something, but if they were the other way up it would reduce unsprung mass - unless the internals of the shock (connected to the piston rod) are heavy.

Psydwaze

Founding Member

... with the coilover setup (looking at the front) what reason do the coilovers have to be mounted the way they are? ...if they were the other way up it would reduce unsprung mass ...

The VariShock body and most of the valve mechanism is machined from aluminum, compared to the steel piston and jam nut at the opposite end. The difference in weight between the two ends isn't as large as you might think. The shock can be mounted inverted without any issues for a minor improvement in unsprung weight, but you'll lose the convience of having easy access to the adjusting knobs.

bnickel

Founding Member

The VariShock body and most of the valve mechanism is machined from aluminum, compared to the steel piston and jam nut at the opposite end. The difference in weight between the two ends isn't as large as you might think. The shock can be mounted inverted without any issues for a minor improvement in unsprung weight, but you'll lose the convience of having easy access to the adjusting knobs.

hye Lino, i sent you a PM regarding another product, did you get it. just curious

KiwiGT

Member

Has anybody gone from an 'Opentracker' rollerised type suspension system to TCP and can advise whether there is a significant handling improvement ?

My 66 GT has boxed LCA's and UCA's, rollerised spring perches and LCA, shelby drop, 600lb springs, revalved koni's, bump steer kit, rollerised shelby quick steer kit, rollerised strut rods ,1 1/4" sway bar at the front with standard 66 GT manual steering box . Also G/w subframe connectors. Rear has 150lb leaf springs, Koni's, underide bars with rod ends, heavy shackles and delrin bushes. All of this stuff is from Cobra Automotive.

My car had the stock A code 225 hp engine and I used to think my car handled reasonably well. I've just installed a 450hp crate engine and now (predictably) find I've got more hp than handling and want to go to the next stage in the never ending quest for upgrading.

I like the TCP approach because they seem to offer integrated solutions, and seem to undertake a research and development approach prior to releasing stuff onto the market.

Can anbody advise whether there will be any significant gains in handling if I replace my current systems with TCP products in the front and rear suspension along with their power steering rack ?

My 66 GT has boxed LCA's and UCA's, rollerised spring perches and LCA, shelby drop, 600lb springs, revalved koni's, bump steer kit, rollerised shelby quick steer kit, rollerised strut rods ,1 1/4" sway bar at the front with standard 66 GT manual steering box . Also G/w subframe connectors. Rear has 150lb leaf springs, Koni's, underide bars with rod ends, heavy shackles and delrin bushes. All of this stuff is from Cobra Automotive.

My car had the stock A code 225 hp engine and I used to think my car handled reasonably well. I've just installed a 450hp crate engine and now (predictably) find I've got more hp than handling and want to go to the next stage in the never ending quest for upgrading.

I like the TCP approach because they seem to offer integrated solutions, and seem to undertake a research and development approach prior to releasing stuff onto the market.

Can anbody advise whether there will be any significant gains in handling if I replace my current systems with TCP products in the front and rear suspension along with their power steering rack ?

reenmachine

Dirt-Old 20+Year Member

Has anybody gone from an 'Opentracker' rollerised type suspension system to TCP and can advise whether there is a significant handling improvement ?

My 66 GT has boxed LCA's and UCA's, rollerised spring perches and LCA, shelby drop, 600lb springs, revalved koni's, bump steer kit, rollerised shelby quick steer kit, rollerised strut rods ,1 1/4" sway bar at the front with standard 66 GT manual steering box . Also G/w subframe connectors. Rear has 150lb leaf springs, Koni's, underide bars with rod ends, heavy shackles and delrin bushes. All of this stuff is from Cobra Automotive.

My car had the stock A code 225 hp engine and I used to think my car handled reasonably well. I've just installed a 450hp crate engine and now (predictably) find I've got more hp than handling and want to go to the next stage in the never ending quest for upgrading.

I like the TCP approach because they seem to offer integrated solutions, and seem to undertake a research and development approach prior to releasing stuff onto the market.

Can anbody advise whether there will be any significant gains in handling if I replace my current systems with TCP products in the front and rear suspension along with their power steering rack ?

You've gone so far with the front suspension that the difference up there won't be drastic, but it would be nice to gain the adjustability. Probably not worth chucking all of those high-end parts.

IMO, you'd get a lot out of the rack & pinion. More positive feel with better feedback and precision.

Any of the TCP rear setups will locate your rear axle far better than the leafs will (yielding more predictable handling), and I'd wager that you'll gain back ride quality at the same time. You'll also be able to hook that 450 hp up in a straight line.

KiwiGT

Member

You've gone so far with the front suspension that the difference up there won't be drastic, but it would be nice to gain the adjustability. Probably not worth chucking all of those high-end parts.

IMO, you'd get a lot out of the rack & pinion. More positive feel with better feedback and precision.

Any of the TCP rear setups will locate your rear axle far better than the leafs will (yielding more predictable handling), and I'd wager that you'll gain back ride quality at the same time. You'll also be able to hook that 450 hp up in a straight line.

Thanks Reen. Thats pretty much in line with my thinking. The rear end isn't as good handling as the front ..but it didn't seem to matter as much with only 225hp and C4

.....450hp and manual gearbox necessitates improvement at the rear..

.....450hp and manual gearbox necessitates improvement at the rear.. I bought my car off your dad at KAR, it was a good purchasing experience.

Similar threads

- Replies

- 0

- Views

- 167

- Replies

- 65

- Views

- 4K

- Replies

- 110

- Views

- 9K

- Replies

- 3

- Views

- 1K

Progress Thread

2004 Comp Orange GT

- Replies

- 9

- Views

- 2K