cbarr300

Member

exactly!

if you can isolate the parts...then it makes diagnosing things a lot easier.

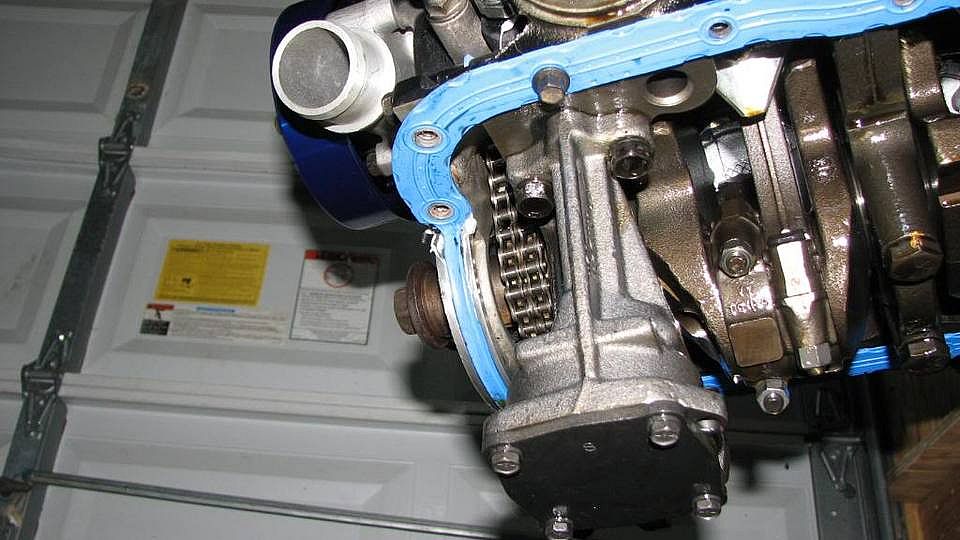

I would check your oil pump shaft.

There's a clip on the shaft..and if the dizzy shaft hits that it won't go down anymore. I had a buddy that had a similar issue with the dizzy not going all the way down. He just took the dizzy and hit it on there kinda hard...and it sorta pushed that clip down so the dizzy ended up sitting flush.

I wouldn't recommend doing that....cuz it's not really the proper way...but it did work and is still working fine 50,000 miles later. Btw, the shaft he used was an ARP piece.

if you can isolate the parts...then it makes diagnosing things a lot easier.

I would check your oil pump shaft.

There's a clip on the shaft..and if the dizzy shaft hits that it won't go down anymore. I had a buddy that had a similar issue with the dizzy not going all the way down. He just took the dizzy and hit it on there kinda hard...and it sorta pushed that clip down so the dizzy ended up sitting flush.

I wouldn't recommend doing that....cuz it's not really the proper way...but it did work and is still working fine 50,000 miles later. Btw, the shaft he used was an ARP piece.

). Since you noted that it only happens with the distributor is installed, I'd say that isolates it as being the culprit. I know the ARP hardened oil pump shafts can be a little on the long side and require removing a little material off the bottom of the distributor shaft, so possibly the Melling shafts share this problem, as well? The only thing I could really suggest is maybe shoot a PM or email to

). Since you noted that it only happens with the distributor is installed, I'd say that isolates it as being the culprit. I know the ARP hardened oil pump shafts can be a little on the long side and require removing a little material off the bottom of the distributor shaft, so possibly the Melling shafts share this problem, as well? The only thing I could really suggest is maybe shoot a PM or email to