Hey guys, back again.... Thanks for the guys who helped with my hydraulic clutch issues!! Now its driveable, but the motor is noisy as hell coming from the valve covers. Here is what I have done to the motor, on open chamber 4V heads.

Now its driveable, but the motor is noisy as hell coming from the valve covers. Here is what I have done to the motor, on open chamber 4V heads.

- CompCams Magnum series .530 list cam

- Brand new lifters and double roller timing chain

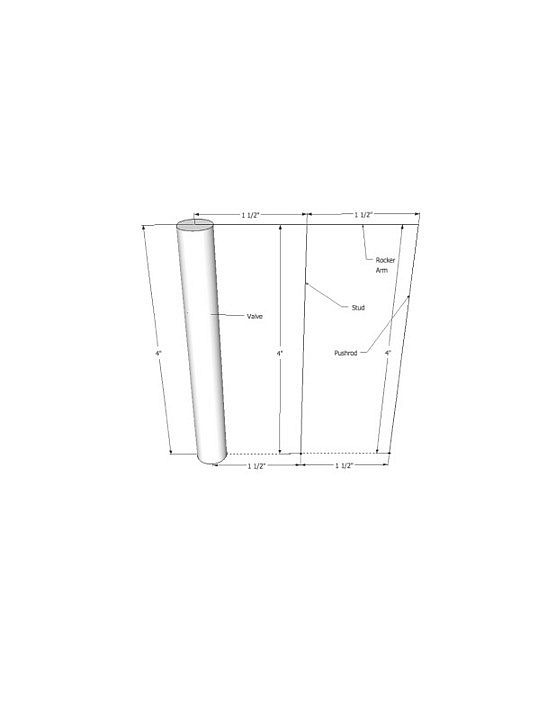

-new pushrods and Crane Cams adjustable stud conversion kit

- new YBB stainless roller rockers

- Doube valve springs (spring pressure checked by machine shop, ok for set-up)

My buddy from the machine shop came over and we did the valve lash per-instructions. Fired it up and broke the cam in. It was still noisy so we gave it another 1/2 turn adjustment. It still sounds like there is not enough pre-load on the lifters. What would be my next step? I'm afraid to adjust them while the motor is running, I dont want to wipe my cam out from putting excessive pre-load...

I dont want to wipe my cam out from putting excessive pre-load...

Now its driveable, but the motor is noisy as hell coming from the valve covers. Here is what I have done to the motor, on open chamber 4V heads.

Now its driveable, but the motor is noisy as hell coming from the valve covers. Here is what I have done to the motor, on open chamber 4V heads.- CompCams Magnum series .530 list cam

- Brand new lifters and double roller timing chain

-new pushrods and Crane Cams adjustable stud conversion kit

- new YBB stainless roller rockers

- Doube valve springs (spring pressure checked by machine shop, ok for set-up)

My buddy from the machine shop came over and we did the valve lash per-instructions. Fired it up and broke the cam in. It was still noisy so we gave it another 1/2 turn adjustment. It still sounds like there is not enough pre-load on the lifters. What would be my next step? I'm afraid to adjust them while the motor is running,

I dont want to wipe my cam out from putting excessive pre-load...

I dont want to wipe my cam out from putting excessive pre-load...