Hey guys i just got another coupe car from a friend of mine that said his brother just freshened up the bottom end in. He said his brother put rod and main bearings in it and rings and a new oil pump. For the first week or so of driving it the oil pressure was right on, cold at start up would be about 65- 75 -80ish pounds and more if you twisted it up, and would fall at idle when hot to 30 -40 pounds, pretty normal in my book, so i noticed the other night driving it to a friends house in 5th gear on the highway at about 2000rpms that there was only about 25psi of oil pressure!! I changed the oil and went to a 15w40 and put a fl1a filter on it in hopes of maybe a faulty oil filter but no better, i tried another gauge and same thing, so now on a cold start it slowly builds to 20psi at idle if you pull out and run the rpms up to say 4500 it will ring off 100psi no problem but once its warm and idleing now it drops to 8-10 psi what could have happened so suddenly for the loss of pressure, any ideas guys? i suppose i will pull the motor and check it out, i first thought maybe a blown out oil galley plug and still could be i suppose but would it even build that much pressure with the rpms? Everything i've read seems to suggest that when that happens people are losing all pressure? Sorry about the long post but i didnt know how else exactly to tell the story

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mystery oil pressure problem

- Thread starter 1989fiveohman

- Start date

-

Sponsors (?)

gearheadboy

15 Year Member

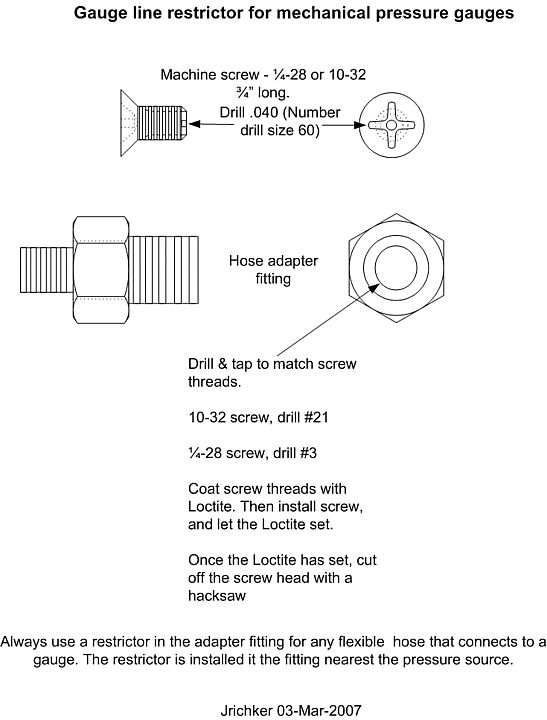

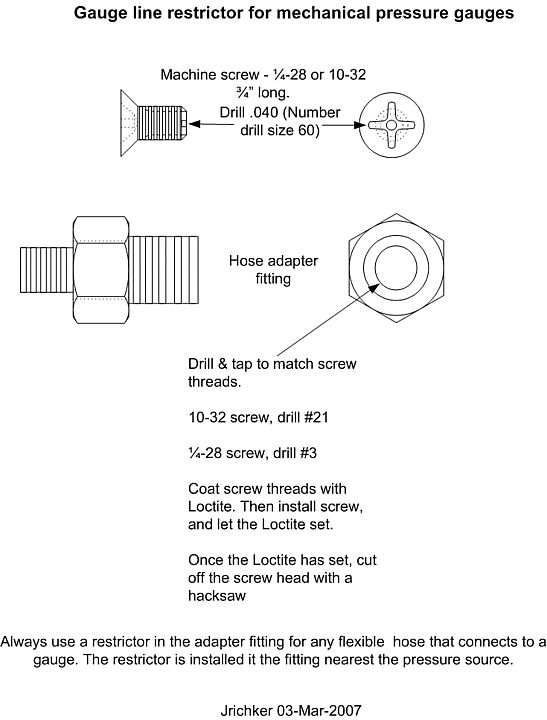

Mechanical oil pressure gauge installation..

1.) Remove old pressure sender. It is located down by the oil filter and has 1 wire on a push on screw connector.

2.) Install ¼” pipe tee fitting with a short ¼” nipple on the place where you removed the oil pressure sender.

3.) Install the original oil pressure sender back in one of the tee ports.

4.) Install the gauge line restrictor in the remaining port of the tee.

5.) Connect the flex tubing or hydraulic hose to the gauge restrictor. Be sure to route the tubing or hose away from the exhaust manifolds. Be sure to either use hydraulic hose or oil and heat resistant flex tubing for the pressure line. Do not use copper tubing for the connection to the gauge restrictor or engine. Over a period of time, the vibration will work harden the tubing and cause it to crack and fail.

6.) If the gauge is going to mount under the hood, connect it to the end of the hose or flex tubing. Use some Tie-wraps to secure the gauge and its plumbing to the wiring harness on the driver’s side inner fender.

7.) If the gauge is going to mount in the passenger compartment you get to find a place to run the tubing through the firewall. I suggest that you pick your spot from the inside since that is the area with the most difficult access. Do not run the tubing through the exact same hole as the steering shaft. It will tangle up with the steering shaft and cause major problems.

8.) Install the gauge inside the car in the location of your choosing. Connect the pressure line to the gauge and secure it out of the way of moving parts with Tie-wraps.

9.) Be sure to ground the gauge lighting wire to clean, shiny bare metal. Connect the other wire from the gauge lighting to a light blue/red wire on the radio wiring harness. There are 2 connectors in the radio wiring harness, but only one of them has the light blue/red wire you need for gauge illumination. Solder the gauge lighting wire to the light blue/red wire on the radio harness and cover the soldered joint with heat shrink.

How to solder like a pro - Ford Fuel Injection » How To Solder Like a Pro a must read for any automotive wiring job.

Be sure to use a gauge restrictor fitting in the pressure line going to the gauge. The restrictor will prevent all of the engine's oil supply from ending up on the pavement before you can stop it if the gauge line fails. I had a gauge line rupture, and the restrictor fitting saved my engine from serious damage.

1.) Remove old pressure sender. It is located down by the oil filter and has 1 wire on a push on screw connector.

2.) Install ¼” pipe tee fitting with a short ¼” nipple on the place where you removed the oil pressure sender.

3.) Install the original oil pressure sender back in one of the tee ports.

4.) Install the gauge line restrictor in the remaining port of the tee.

5.) Connect the flex tubing or hydraulic hose to the gauge restrictor. Be sure to route the tubing or hose away from the exhaust manifolds. Be sure to either use hydraulic hose or oil and heat resistant flex tubing for the pressure line. Do not use copper tubing for the connection to the gauge restrictor or engine. Over a period of time, the vibration will work harden the tubing and cause it to crack and fail.

6.) If the gauge is going to mount under the hood, connect it to the end of the hose or flex tubing. Use some Tie-wraps to secure the gauge and its plumbing to the wiring harness on the driver’s side inner fender.

7.) If the gauge is going to mount in the passenger compartment you get to find a place to run the tubing through the firewall. I suggest that you pick your spot from the inside since that is the area with the most difficult access. Do not run the tubing through the exact same hole as the steering shaft. It will tangle up with the steering shaft and cause major problems.

8.) Install the gauge inside the car in the location of your choosing. Connect the pressure line to the gauge and secure it out of the way of moving parts with Tie-wraps.

9.) Be sure to ground the gauge lighting wire to clean, shiny bare metal. Connect the other wire from the gauge lighting to a light blue/red wire on the radio wiring harness. There are 2 connectors in the radio wiring harness, but only one of them has the light blue/red wire you need for gauge illumination. Solder the gauge lighting wire to the light blue/red wire on the radio harness and cover the soldered joint with heat shrink.

How to solder like a pro - Ford Fuel Injection » How To Solder Like a Pro a must read for any automotive wiring job.

Be sure to use a gauge restrictor fitting in the pressure line going to the gauge. The restrictor will prevent all of the engine's oil supply from ending up on the pavement before you can stop it if the gauge line fails. I had a gauge line rupture, and the restrictor fitting saved my engine from serious damage.

Attachments

I'm assuming he already has a mechanical gauge because how would he know what pressure he had before?

With that said, the numbers seem to be both ends of the spectrum, hot idle at 40psi is pretty high, below 10 is pretty low.

You burning any oil?

With that said, the numbers seem to be both ends of the spectrum, hot idle at 40psi is pretty high, below 10 is pretty low.

You burning any oil?

well an update for tonight, i pulled the dizzy out and stuck a 1/4 socket on the pump driveshaft and you spin the driveshaft counter clockwise and there is no resistance at all, i can see the one oil galley plug is still intact right next to the distributor gear, but i cant see the other but i'm leaning more toward the pump going out or possible the bolts could be coming loose that attach the pump to the block or the bolts coming loose that attach the pickup to the pump, either way i'm not gonna run the engine anymore and pulling the motor in the near future to find out exactly whats went wrong. p.s i have a mechanical gauge in the car, an auto meter phantom gauge, and the other gauge was summit racing mechanical gauge and they both read exactly the same

87stanglx302

New Member

- Dec 18, 2012

- 2

- 0

- 1

i just bought a 87 lx 5.0 it has a sunpro oil pressure gauge on it. when the car is cold after sitting all night it will have 40 psi of oil pressure as it warms up the pressure will drop to 0 but no noise from the motor and it has been like this for a month going down the road it will run about 18 psi of oil pressure i can't figure it out at all could someone help if they have also had this problem

Sounds like bad bearings from my experience.i just bought a 87 lx 5.0 it has a sunpro oil pressure gauge on it. when the car is cold after sitting all night it will have 40 psi of oil pressure as it warms up the pressure will drop to 0 but no noise from the motor and it has been like this for a month going down the road it will run about 18 psi of oil pressure i can't figure it out at all could someone help if they have also had this problem

If that's the case, get yourself prepared to buy an explorer engine to replace yours.

87stanglx302

New Member

- Dec 18, 2012

- 2

- 0

- 1

thats kinda what i was afraid u thinking there is any chance i could rebearing the bottom end and put a new oil pump in and save the motor

thats kinda what i was afraid u thinking there is any chance i could rebearing the bottom end and put a new oil pump in and save the motor

It's not worth the trouble.

Explorer engines are $500, sometimes less.

been there done that. explorer short block with under 100k miles ran me 80 bux. Factor in the cost of a master gasket kit, new head bolts, and intake bolts and I was up and running for about $300 or so.Sounds like bad bearings from my experience.

If that's the case, get yourself prepared to buy an explorer engine to replace yours.

If the car is a toy run it until it blows. I drove mine for over a year and a half with bad oil pressure. Would drop to zero when I floored it and it would rattle like a bitch while blowing smoke out the tails. It was still running when I pulled it.

blacksheep-1

Member

- Oct 21, 2006

- 322

- 4

- 18

I just had a motor that wiped out the bottom end, it had 60 psi pressure I revved it up and it went to about 75 then the oil pump relief valve kicked in and it dropped to around 40...then went down more and more until about 10 psi then zero at idle. There was some crap that went through the oil pump and hung the oil pressure relief valve open so when the engine went back to idle,...no pressure. Just a thought, you can probably jack the engine up and lower the pan to change the pump.

you can probably jack the engine up and lower the pan to change the pump.

That plan almost never works.

In my time as a 5.0 owner (almost 20 years now) with a friend that owns a shop specializing in mustangs, i've not ever seen or known anyone that changed just the pump and had it make a difference.

It's a risky plan that is a serious PITA. Pulling the pump with the engine in the car is not for a novice, in fact it's easier for most people to pull the engine.

I pulled the pan with the engine in the car this last summer and that was just to replace a leaky gasket. I will never do it again. far easier to drop pull the engine.

65ShelbyClone

Founding Member

Bad bearings often manifest as oil pressure that drops as RPM increases and often leave silver in the oil pan. Pulling the pan probably isn't a bad idea at this point anyway...

Yup, it's a lesson you only need to learn once.I pulled the pan with the engine in the car this last summer and that was just to replace a leaky gasket. I will never do it again. far easier to drop pull the engine.

well guess what , i pulled the motor and put it on the stand and turned it upside down to take the oilpan off and i heard something make a clink noise inside so i pulled the pan off and instead of a oil galley plug laying there it was a craftsman 1/4 in drive 12 point socket laying there, with a very slight flat spot on the 12 point end of it! so i pulled the oil pump and screen off of it and a few little tiny pieces of i suppose the block where the socket must have struck it, was laying in the pump. i took the cover off the pump to see inside it and seen the bypass valve was stuck, so that solves the mystery! i looked and looked for any damage to the block where the socket may have struck a piston skirt or something but i cant see any visible damage that really stands out, so i cleaned it out with some spay lube and compressed air really good and just gonna put a new pump in it and see what it does

sounds like someone was trying to spin the driveshaft with it and dropped it down the hole and left it rather than try to drop the pan.

Similar threads

- Replies

- 27

- Views

- 2K

- Replies

- 10

- Views

- 979

- Replies

- 22

- Views

- 1K

- Replies

- 1

- Views

- 1K

- Replies

- 28

- Views

- 3K