Trying to figure out the cause of feedback/interference that is coming through radio. It's a whining noise that increases with RPM. The noise has been present for about a year but its starting drive me nuts. Any ideas?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical Radio Interference

- Thread starter Clayton302

- Start date

-

Sponsors (?)

- Mar 30, 2005

- 4,749

- 95

- 134

trinity_gt

10 Year Member

Factory, I believe the previous owner had it out. I checked the install its clean. Ground Loop? I relocated the battery to the truck but ran the wires to the factory locations and the noise was there before anyways. All electronics work great.

Could give this a try?You need a noise suppression choke coil on the power supply line, try radio shack.

- Mar 30, 2005

- 4,749

- 95

- 134

Before you buy anything might wait to see what else trinity has to say since it is stock and he has a lot of knowledge. My guess is that the battery relocate allowed more noise and you need a choke coil though.

trinity_gt

10 Year Member

Thanks KT.

OP, relocating the battery but running "the wires to the factory locations" can still generate and/or aggravate electrical noise especially if the battery ground lead was one of those run back to the original location. Was the battery grounded to the chassis near the battery in the back or was its lead run alongside the positive lead all the way to the front?

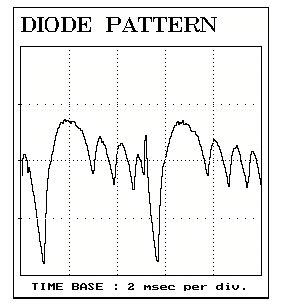

As for the original noise, one thing that immediately comes to mind is the quality of the alternator output. A bad diode in the rectifier bridge or an open stator winding can generate a hell of a "ripple" in the output voltage of the alternator producing an electrical noise that will vary with engine RPM. If you can, have the alternator checked for what's called "AC ripple".

OP, relocating the battery but running "the wires to the factory locations" can still generate and/or aggravate electrical noise especially if the battery ground lead was one of those run back to the original location. Was the battery grounded to the chassis near the battery in the back or was its lead run alongside the positive lead all the way to the front?

As for the original noise, one thing that immediately comes to mind is the quality of the alternator output. A bad diode in the rectifier bridge or an open stator winding can generate a hell of a "ripple" in the output voltage of the alternator producing an electrical noise that will vary with engine RPM. If you can, have the alternator checked for what's called "AC ripple".

I originally ran the ground straight to the chassis out back but started having issues with odd codes. I then took a high quality, 600V, 2/0 AWG, welding cable and ran it straight to the motor on the opposite side of the power cable which is ran inside the car and the ground is ran outside. I did this to eliminate any ground loop issues and all the electronics seem to work better/correct and the codes are gone, my tuner suggested this.

I will check the alt for AC ripple with my volt meter. If you have limit spec for this that would be helpful, if not I'm sure I can find something. The noise did slightly increase with the original relocation, ground configuration and there was no change once I reconfigured the ground. If it is alt related I could see this causing the increase in noise because the battery cable in now closer to the wiring harness for the inside power wires.

One thing worth noting is the harmonic balancer was increased in size by 15%. The reason I mention this is because the alt is now over driven 15% at any given RPM. With the factory balancer the noise was always there but only at higher RPMs. The whining noise is now audible a lower RPMs.

Unfortunately I did the battery relocation, harmonic balancer, cobra tank, and HE coolant tank at the same time so can't say for sure which caused the increase but I'm pretty sure the fuel tank and coolant tank are out of the equation

Thanks gents for the help thus far

I will check the alt for AC ripple with my volt meter. If you have limit spec for this that would be helpful, if not I'm sure I can find something. The noise did slightly increase with the original relocation, ground configuration and there was no change once I reconfigured the ground. If it is alt related I could see this causing the increase in noise because the battery cable in now closer to the wiring harness for the inside power wires.

One thing worth noting is the harmonic balancer was increased in size by 15%. The reason I mention this is because the alt is now over driven 15% at any given RPM. With the factory balancer the noise was always there but only at higher RPMs. The whining noise is now audible a lower RPMs.

Unfortunately I did the battery relocation, harmonic balancer, cobra tank, and HE coolant tank at the same time so can't say for sure which caused the increase but I'm pretty sure the fuel tank and coolant tank are out of the equation

Thanks gents for the help thus far

trinity_gt

10 Year Member

I originally ran the ground straight to the chassis out back but started having issues with odd codes. I then took a high quality, 600V, 2/0 AWG, welding cable and ran it straight to the motor on the opposite side of the power cable which is ran inside the car and the ground is ran outside. I did this to eliminate any ground loop issues and all the electronics seem to work better/correct and the codes are gone, my tuner suggested this.

The heavy cable will help with returning starter currents to the battery but you'll still want to tie the chassis to the battery using, say, an 8- or 10-AWG to provide a low-inductance ground return from the chassis.

I will check the alt for AC ripple with my volt meter. If you have limit spec for this that would be helpful, if not I'm sure I can find something.

I think anything approaching 0.5V (500mV) would be cause for concern.

As well, if you can, use a scope to measure the ripple because many DVMs may not be able to accurately measure non-sinusoid ripple. The issue is that most meters with an "AC" setting are designed to measure a true sinusoidal waveform and will report incorrect numbers for what amounts to 0.5V of peak to peak noise on a 14V DC offset.

A bad diode might produce a waveform like this:

One thing worth noting is the harmonic balancer was increased in size by 15%. The reason I mention this is because the alt is now over driven 15% at any given RPM. With the factory balancer the noise was always there but only at higher RPMs. The whining noise is now audible a lower RPMs.

Overspeeding the alternator can toss the windings in the field (i.e. the rotor) but shouldn't affect the rectifier bridge.

Attachments

I did just that.The heavy cable will help with returning starter currents to the battery but you'll still want to tie the chassis to the battery using, say, an 8- or 10-AWG to provide a low-inductance ground return from the chassis.

I have a good scope at work so I will use it.As well, if you can, use a scope to measure the ripple because many DVMs may not be able to accurately measure non-sinusoid ripple. The issue is that most meters with an "AC" setting are designed to measure a true sinusoidal waveform and will report incorrect numbers for what amounts to 0.5V of peak to peak noise on a 14V DC offset.

Thanks Man!

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 26

- Views

- 2K

- Replies

- 7

- Views

- 2K

- Replies

- 1

- Views

- 1K