That is a common issue. Basically the longer length of the intake creates a delay between what the VAM says and the change actually taking place. So the computer sees a certain amount of air coming in, tries to modify the fuel and idle, and overshoots, by the time it measures the change, the conditions have changed again.

The initial solution is to increase the base idle speed. Long term, if you can upgrade from the stock computer to speed density (PIMP, Megasquirt) or can do a MAF swap (Lighting MAF and Quarterhorse) the issue can be overcome and corrected.

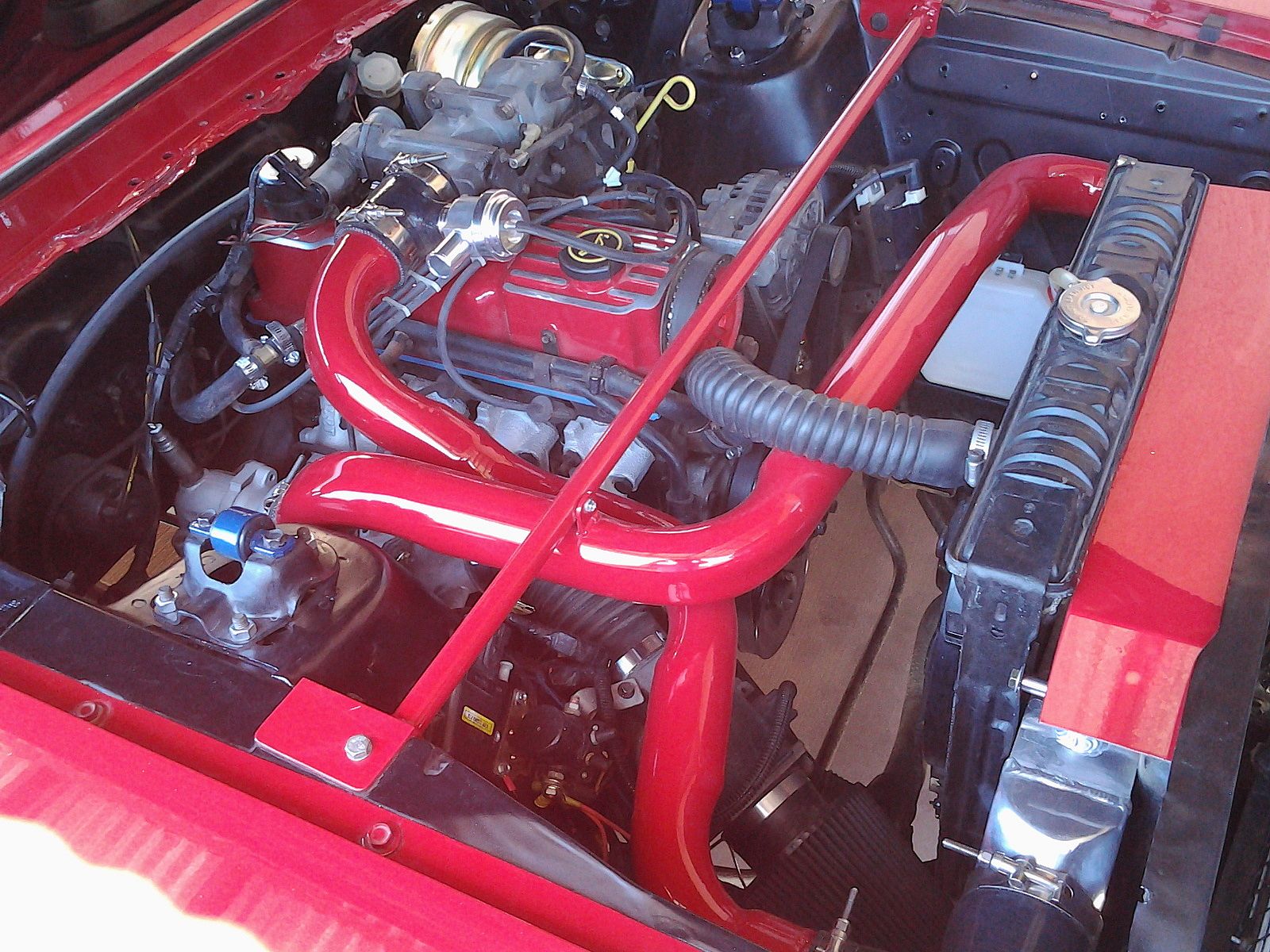

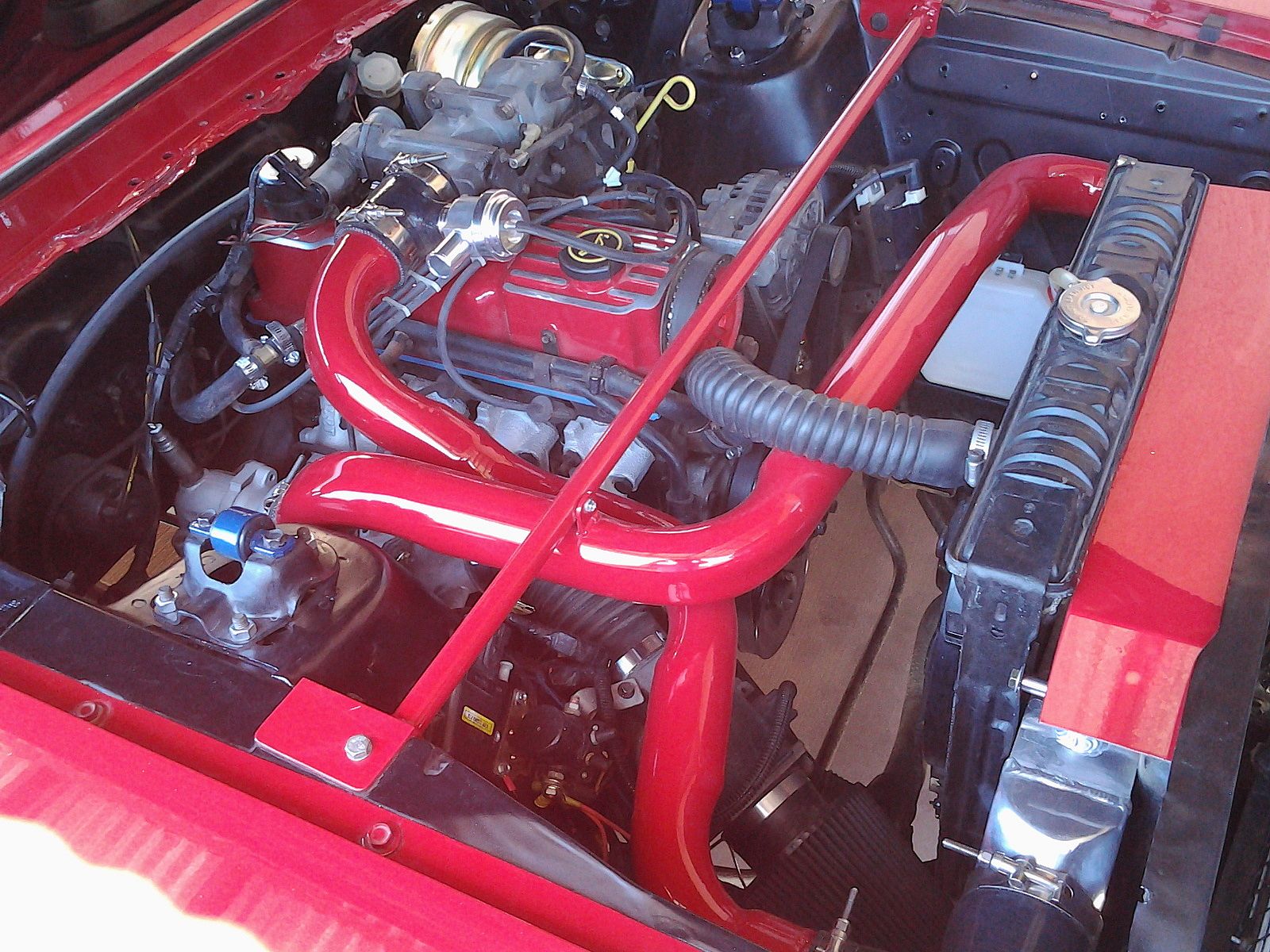

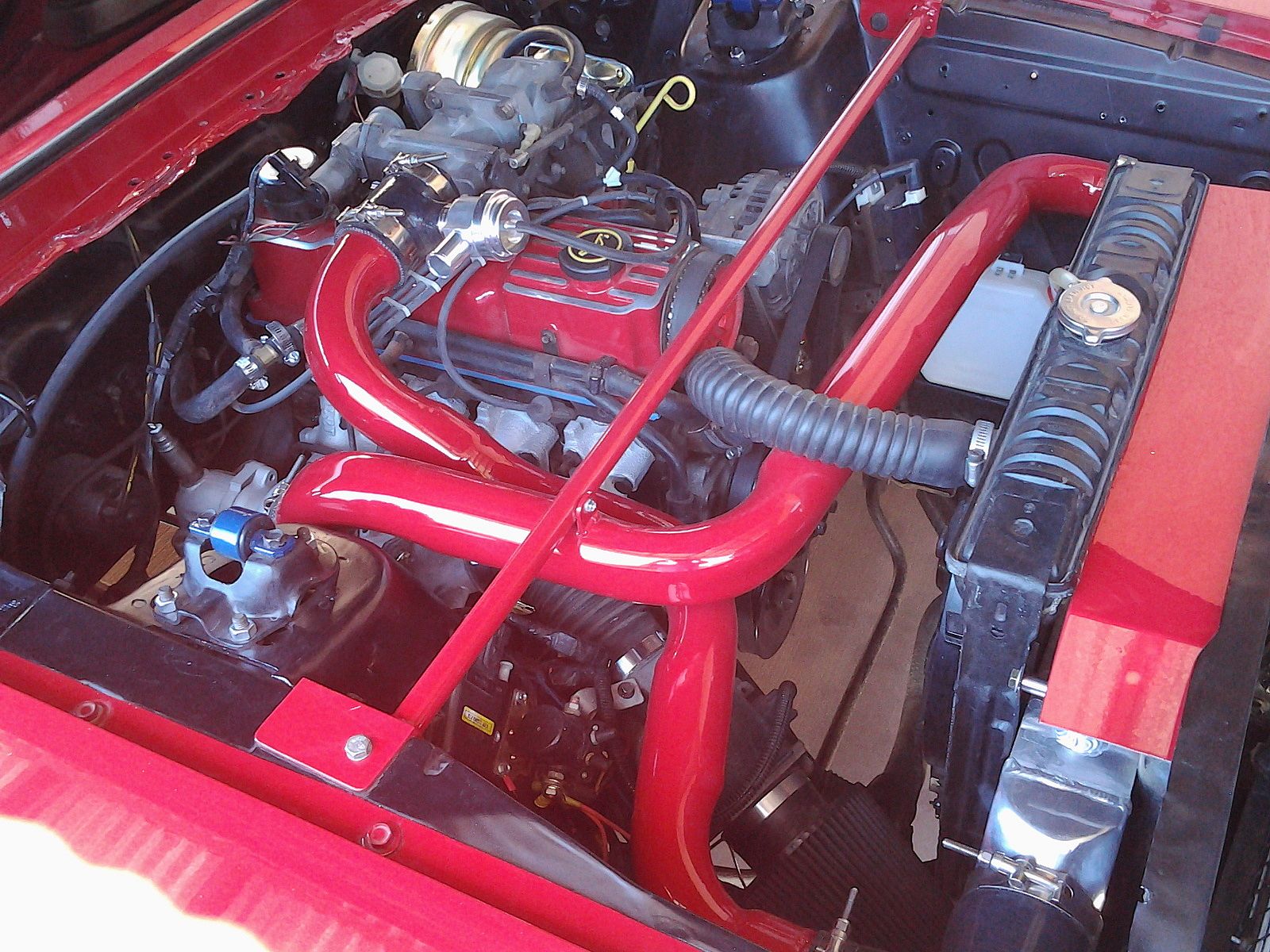

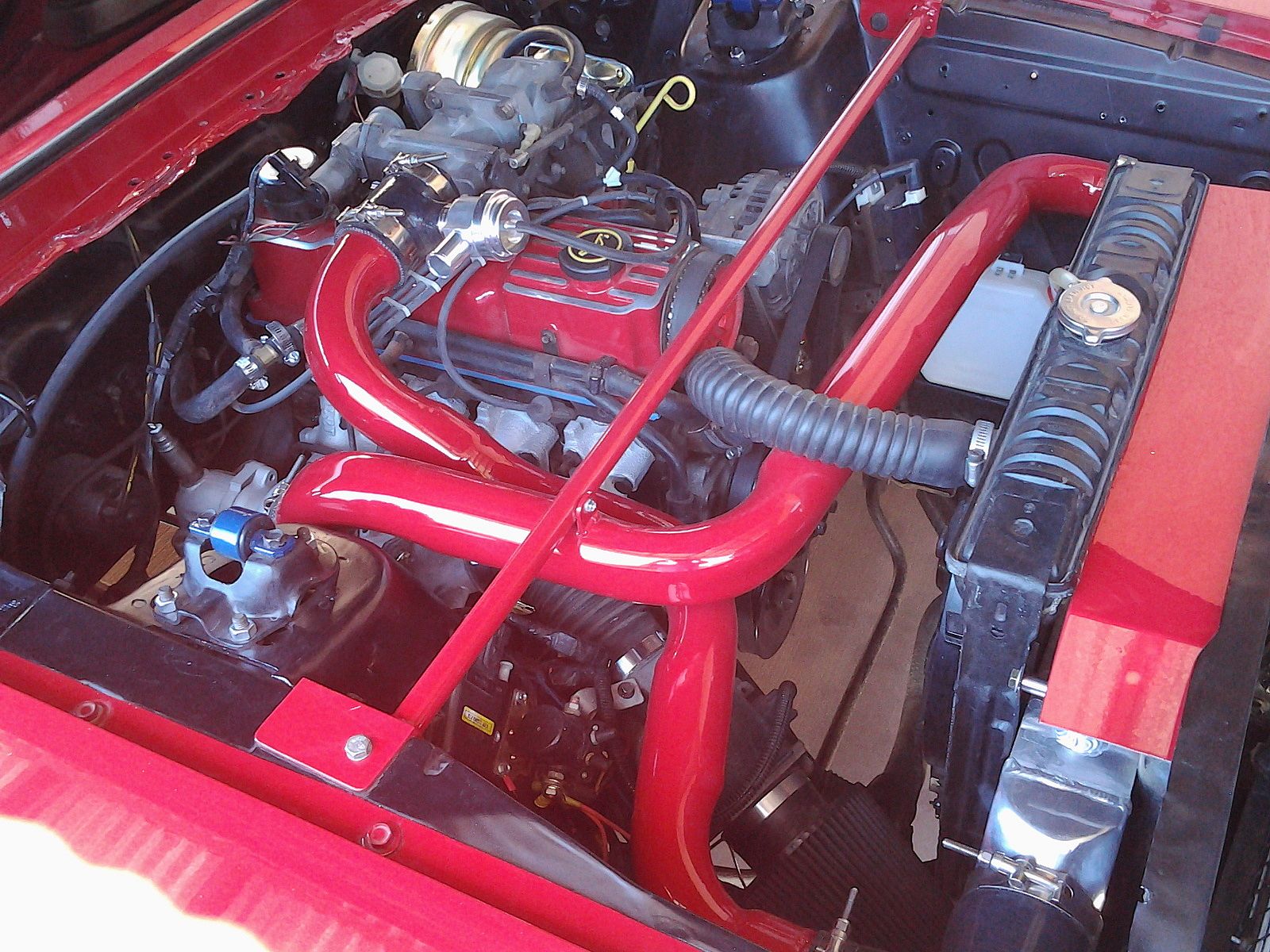

Myself I would not have opted for a FMIC built from exhaust tubing. Every elbow costs flow, and increases pressure. This means your turbo works harder to produce any given amount of boost. On a N/A car in an exhaust system the effects are less noticeable, but on turbo applications, I use all mandrel bends everywhere.

You need to enclose the filter so that it is only pulling air from outside the engine compartment. Otherwise you are taking hot air (which is less dense than cold air), compressing it, which makes it hotter, then trying to cool it, and then trying to produce maximum power with it, but the computer has no choice but to pull timing to prevent knocking. A lot of this will mess with the VAM calculations.