You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Installing The Manual Trans

- Thread starter gnx547

- Start date

-

Sponsors (?)

larrym1961

5 Year Member

MFE92 is right, never draw your trans in by the bolts. I have heard and read that it helps to have someone push the clutch pedal in while installing the transmission. Makes it go in a lot easier.

Another trick my Step Father taught me years ago was to file off or chamfer the sharp edges of the clutch plate splines to help the trans slide into the clutch easier also.

Another trick my Step Father taught me years ago was to file off or chamfer the sharp edges of the clutch plate splines to help the trans slide into the clutch easier also.

Last edited:

modulistic

Active Member

- Nov 26, 2002

- 383

- 30

- 29

Did you get the alignment tool? Its almost necessary sometimes. Also, it helps to have someone move the tailshaft with the trans in gear to help line up the splines. Double check the angle you are trying to install the trans, too.

Dave2000GT

Active Member

How far from all the way in?

If like 1/4 in then get someone to push in the clutch. If like 1" or more then its the splines, rotate the trans axially, get it to line up just keep rotating/pushing. Doesnt really matter if in gear or not.

If like 1/4 in then get someone to push in the clutch. If like 1" or more then its the splines, rotate the trans axially, get it to line up just keep rotating/pushing. Doesnt really matter if in gear or not.

Dave2000GT

Active Member

Also if it STILL wont go.. Then talk to me. I had a rare/messed up situation where the trans wouldn't go that no one could figure out..

Dave2000GT

Active Member

Well if its over an inch it the spline line up. It shouldnt take force, just adjust angle, restab. Easiest if you're doing it by hand, benchpress style, using a jack really limits the movement you may need.There is about an inch or more. I don't want to force and wiggle it so hard where I can damage the pressure plate fingers. But I'm putting moderate force on it. What did you find out the problem was with your trans that wouldn't go in?

My issue was the last 1/4". Car drove OK prior, but clutch starting to slip and made some bearing noise. So i pulled it, replaced clutch, pilot and throwout. Wouldnt go back in. Turns out it had the 94/95 input shaft, on my fox. Previous owner/mechanic had forced it in somehow, damaging pilot bearing but it did work. Took awhile to figure out as it was the last thing id expect from a previously 'working' setup. Replaced input shaft and i was good after that.

Since you have already removed the transmission, start at step 17...

The clutch is toast. Get out your wallet and tools...

Transmission and Clutch replacement 79-95 V8 Mustangs

Before you get started, buy a Chilton or Haynes shop manual. You will need it for the bolt torques and patterns.

1.) Jack up the car front and rear, use jack stands to be safe. I use some very tall jackstands that I bought for my wife’s SUV to get enough clearance. To get the trans out when using a transmission jack, you will need 22”-25” clearance.

2.) Put a 2x4 wood block under the engine oil pan to support the engine. Jack it up slightly. This prevents damage to the motor mounts when the transmission mount is removed. The oil pan is plenty strong for this purpose. Disconnect the negative battery cable. You will need a couple of extensions and a ½” swivel socket to remove the top starter mount bolt, which is accessed from the front and under the headers. Leave the starter wiring connected unless you plan to change the starter at this time.

3.) Label all the wiring for the transmission before disconnecting it. Disconnect the O2 sensor cables at their connectors. Disconnect the speedo cable by pulling it straight out of the VSS sensor, or by removing the bolt that holds the VSS sensor in place. If you remove the VSS sensor, zip bag & tag it along with the bolt that secures in place.

4.) Remove the drive shaft, the rear bolts are 12 MM. You will need a high quality 12 point wrench for this: do not skimp or you risk rounding off the bolt heads. A helper to step on the brake to keep the drive shaft from turning will be helpful. Use your foot to apply pressure to the wrench to loosen the bolts. Note the yellow markings in the drive shaft and write down their alignment.

5.) Put a catch pan under the rear of the transmission to catch the fluid when you slide the yoke out of the transmission. I recommend that you drain the transmission at this time. There is a pair of pipe plug filler ports on the side of the transmission. Use the lower plug to drain the fluid.

6.) Inside the car, remove the shifter boot and then remove the shifter handle

7.) Remove the H pipe & rear trans cross member. The chassis to cross member bolts are metric, you need a 15 MM & 17 MM socket or wrench. Note the direction and size of the humps on the cross member and write it down. Inspect the rear transmission mount and replace if damaged.

8.) Remove the transmission. You will need a long extension & a universal joint with a ¾” socket. A transmission jack or a helper is almost a must have unless you can bench press 75-100 pounds with ease.

Steps 9-21 are for rear main engine oil seal, clutch removal and replacement.

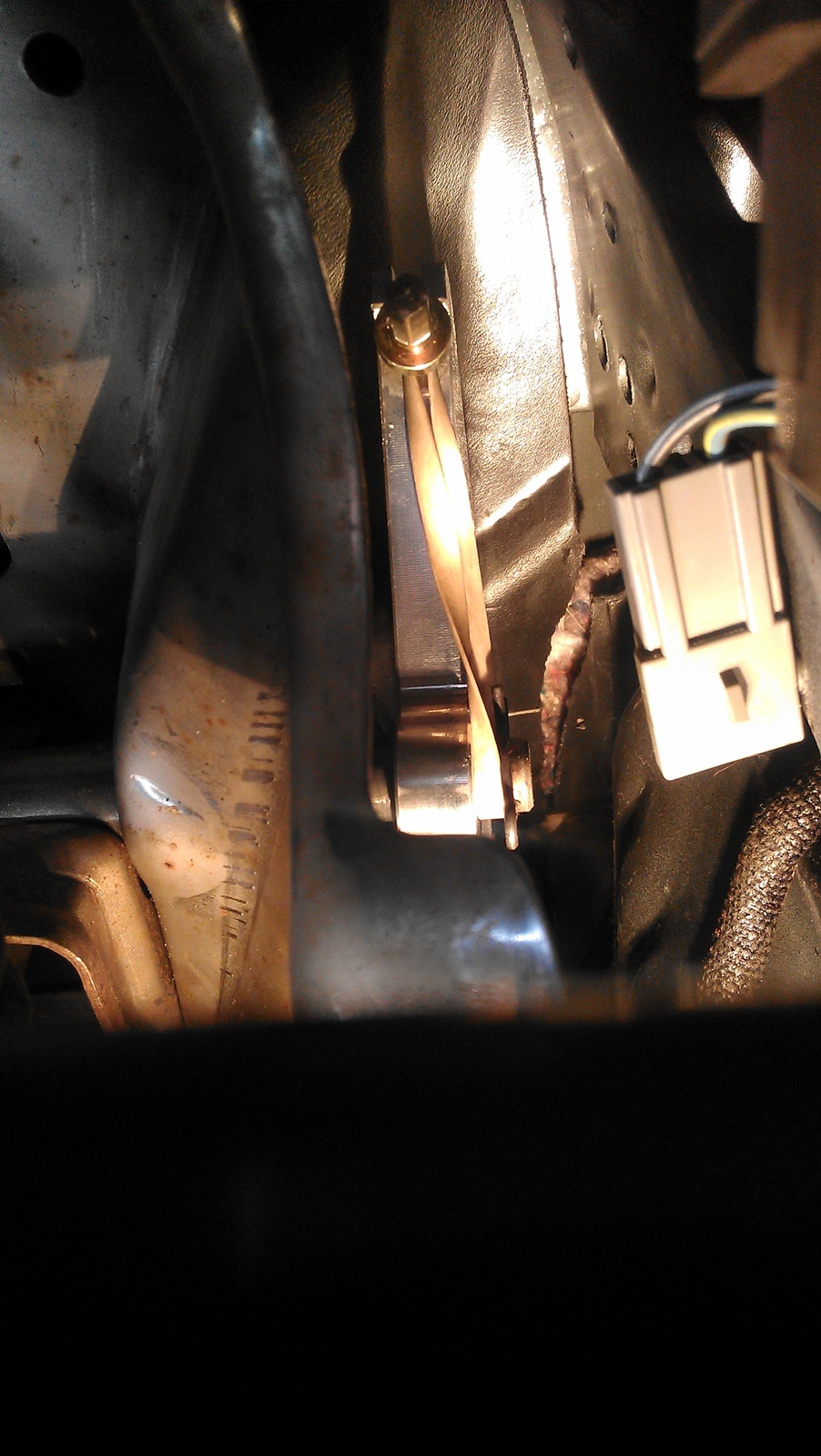

9.) Remove the clutch cable cover and pry the throwout bearing arm forward enough to slide the cable off.

10.Remove the bell housing using the long extension & a universal joint socket. Note how the throwout bearing rides it the throwout bearing arm, and which end faces the clutch pressure plate. Write it down or make a drawing if necessary.

11.) Remove the bolts securing the pressure plate to flywheel. Be sure to label & zip bag them separately from the rest of the parts. Work in a star pattern to reduce stress on the pressure plate mounting tabs.

12.) Remove the flywheel mount bolts, as you will need to either replace or re-surface the flywheel. Be sure to label & zip bag them separately from the rest of the parts. Tap the locator dowels out of the flywheel with a 1/4" pin punch. Zip bag them together with the flywheel bolts.

13.) Inspect the transmission input shaft where the throwout bearing rides. Replace it if worn or damaged.

14.) Inspect the throwout bearing, throwout bearing arm and ball pivot stud for wear or damage.

15.) Inspect the rear oil seal for leakage and replace if required. A pair of drywall screws carefully screwed into the metal part of the seal will enable you to pull it out. Use some acetone & swabs to clean out the place where the old seal fit. Coat the outer metal shell with silicone gasket maker prior to installing it. Use a seal driver or the old seal to drive the new seal in place.

16.) Remove & replace the pilot bearing. A puller borrowed or rented is helpful here. A wood block will be used to drive it home.

--->17.) Install the flywheel, noting that the bolts are an odd pattern, and it only lines up one way so that all the bolts go in easily. Torque to specs according to the shop manual. Install the locator dowels at this time.

18.) Install the clutch disk with the hub springs facing the rear of the car. Use a pilot tool available for $3-$4 from the auto parts store to line it up.

19. Install the pressure plate, be sure to use the pilot tool prior to tightening the pressure plate bolts. Torque to specs according to the shop manual. Remove the pilot tool when you are finished torqueing the bolts.

20.) Install the throwout bearing on the throwout bearing arm, noting the direction of the bearing and it mounting in the arm.

21.) Install the bell housing. Torque to specs according to the shop manual.

22.) Reinstall the clutch cable by prying on the throwout bearing arm. Replacement of the stock cable or quadrant is recommended if you haven’t already done so. With adjustable cables, both nuts go on the back side of the throwout bearing arm.

End of clutch replacement steps

23.) Install the transmission, have the transmission jack or helper at hand to lift it into place. Watch out that the stub of the shifter does not tear the shifter boot. Some transmission mount bolts with the heads cut off can be used to help support the transmission as you slide it home. It may be necessary to press the clutch pedal to get the transmission to slide the last ½” or so. Remove the guide studs if you used them & torque to specs according to the shop manual.

24.) Reinstall the rear crossmember & transmission mount. Torque to specs according to the shop manual.

25.) Reinstall the wiring and speedo cable or VSS sensor if you removed it.

26.) Reinstall the drive shaft, slide the yoke in place. Align the rear yellow markings and install the bolts. A helper to step on the brake to keep the drive shaft from turning will be helpful. Use your foot to apply pressure to the wrench to tighten the bolts.

27.) Remove the jack from under the engine oil pan.

28.) Refill the transmission with the proper fluid. T5’s use Dextron ATF, Tremec 3550’s use GM Synchromesh. There is a pair of pipe plug filler ports on the side of the transmission. Use the top plug as the filler port.

29.) Adjust the clutch cable according the manufacturer’s instructions if you have an adjustable cable & quadrant. Set the emergency brake and use the drag it provides in order to determine where the clutch starts to engage. You should have 1 -1 ½” free play from the top. The cable will not have any slack and will have some preload on it when properly adjusted.

30.) Re-install the H pipe and remaining items.

31.) When you have visually checked all the bolts, fittings and other parts are present and not interfering with each other, then take the car down off the jack stands.

32.) Be prepared to put the car back up on the jack stands to adjust the clutch and tighten up any loose items found after the test drive…

If you have a T5, you may be able to remove the trans & re-install it if you can bench press the 75 lbs that it weighs. If 75 lbs is too heavy, don't hurt yourself, get a trans jack. If your car has a Tremec 3550 or TKO, you will need a helper or trans jack because it weighs 100 + lbs. I built a trans jack from 2x2 angle iron, some swivel casters, 2x4's, 2x6's and a cheap floor jack. PM me if you are interested & I will send you the photos (8 MB) with the write up.

While you are at it, replace the stock cable & quadrant if it is still present. My choice for clutch & quadrant for street use:

Ford Racing M-7560-A302N - Ford Racing Clutch Kits - Overview - SummitRacing.com Ford Racing M-7560-A302N king cobra clutch kit $215-$259

Ford Racing M-6375-B302 - Ford Racing Flywheels - Overview - SummitRacing.com flywheel, cast iron $92

New items – the King Cobra clutch kit may not be in stock, so here’s the replacement:

http://www.summitracing.com/parts/F...ilter=1&query=Part+Type|Throwout+BearingsFord Racing clutch kit #FMS-M-7560-E302, $25, no throwout bearing included with the kit.

http://www.summitracing.com/parts/FMS-M-7548-A/ Ford Racing throwout bearing FMS-M-7548-A $52.

The quadrant needs to be replaced if you use any type of aftermarket cable or adjuster. My preference is a Ford Racing quadrant, adjustable cable and Steeda firewall adjuster. The adjustable Ford Racing cable is just a good as the stock OEM cable. It allows a greater range of adjustment than a stock cable with a aftermarket quadrant and firewall adjuster. Combined with the Steeda adjuster, it lets you set the initial cable preload and then fine tune the clutch engagement point to your liking without getting under the car.

Using a stock OEM cable and a single hook quadrant may result in not having any free pedal travel before the clutch starts to disengage. I found this out the hard way.

See Summit Racing - High Performance Car and Truck Parts l 800-230-3030 for the following parts.

Ford Racing M-7553-B302 - Ford Racing V-8 Mustang Adjustable Clutch Linkage Kits - Overview - SummitRacing.com Cable and quadrant assembly $90

Steeda Autosports 555-7021 - Steeda Autosports Firewall Cable Adjusters - Overview - SummitRacing.com Steeda firewall adjuster. $40

Fix for the quadrant end of the cable popping out of the quadrant when installing a replacement cable courtesy of Grabbin' Asphalt

The clutch is toast. Get out your wallet and tools...

Transmission and Clutch replacement 79-95 V8 Mustangs

Before you get started, buy a Chilton or Haynes shop manual. You will need it for the bolt torques and patterns.

1.) Jack up the car front and rear, use jack stands to be safe. I use some very tall jackstands that I bought for my wife’s SUV to get enough clearance. To get the trans out when using a transmission jack, you will need 22”-25” clearance.

2.) Put a 2x4 wood block under the engine oil pan to support the engine. Jack it up slightly. This prevents damage to the motor mounts when the transmission mount is removed. The oil pan is plenty strong for this purpose. Disconnect the negative battery cable. You will need a couple of extensions and a ½” swivel socket to remove the top starter mount bolt, which is accessed from the front and under the headers. Leave the starter wiring connected unless you plan to change the starter at this time.

3.) Label all the wiring for the transmission before disconnecting it. Disconnect the O2 sensor cables at their connectors. Disconnect the speedo cable by pulling it straight out of the VSS sensor, or by removing the bolt that holds the VSS sensor in place. If you remove the VSS sensor, zip bag & tag it along with the bolt that secures in place.

4.) Remove the drive shaft, the rear bolts are 12 MM. You will need a high quality 12 point wrench for this: do not skimp or you risk rounding off the bolt heads. A helper to step on the brake to keep the drive shaft from turning will be helpful. Use your foot to apply pressure to the wrench to loosen the bolts. Note the yellow markings in the drive shaft and write down their alignment.

5.) Put a catch pan under the rear of the transmission to catch the fluid when you slide the yoke out of the transmission. I recommend that you drain the transmission at this time. There is a pair of pipe plug filler ports on the side of the transmission. Use the lower plug to drain the fluid.

6.) Inside the car, remove the shifter boot and then remove the shifter handle

7.) Remove the H pipe & rear trans cross member. The chassis to cross member bolts are metric, you need a 15 MM & 17 MM socket or wrench. Note the direction and size of the humps on the cross member and write it down. Inspect the rear transmission mount and replace if damaged.

8.) Remove the transmission. You will need a long extension & a universal joint with a ¾” socket. A transmission jack or a helper is almost a must have unless you can bench press 75-100 pounds with ease.

Steps 9-21 are for rear main engine oil seal, clutch removal and replacement.

9.) Remove the clutch cable cover and pry the throwout bearing arm forward enough to slide the cable off.

10.Remove the bell housing using the long extension & a universal joint socket. Note how the throwout bearing rides it the throwout bearing arm, and which end faces the clutch pressure plate. Write it down or make a drawing if necessary.

11.) Remove the bolts securing the pressure plate to flywheel. Be sure to label & zip bag them separately from the rest of the parts. Work in a star pattern to reduce stress on the pressure plate mounting tabs.

12.) Remove the flywheel mount bolts, as you will need to either replace or re-surface the flywheel. Be sure to label & zip bag them separately from the rest of the parts. Tap the locator dowels out of the flywheel with a 1/4" pin punch. Zip bag them together with the flywheel bolts.

13.) Inspect the transmission input shaft where the throwout bearing rides. Replace it if worn or damaged.

14.) Inspect the throwout bearing, throwout bearing arm and ball pivot stud for wear or damage.

15.) Inspect the rear oil seal for leakage and replace if required. A pair of drywall screws carefully screwed into the metal part of the seal will enable you to pull it out. Use some acetone & swabs to clean out the place where the old seal fit. Coat the outer metal shell with silicone gasket maker prior to installing it. Use a seal driver or the old seal to drive the new seal in place.

16.) Remove & replace the pilot bearing. A puller borrowed or rented is helpful here. A wood block will be used to drive it home.

--->17.) Install the flywheel, noting that the bolts are an odd pattern, and it only lines up one way so that all the bolts go in easily. Torque to specs according to the shop manual. Install the locator dowels at this time.

18.) Install the clutch disk with the hub springs facing the rear of the car. Use a pilot tool available for $3-$4 from the auto parts store to line it up.

19. Install the pressure plate, be sure to use the pilot tool prior to tightening the pressure plate bolts. Torque to specs according to the shop manual. Remove the pilot tool when you are finished torqueing the bolts.

20.) Install the throwout bearing on the throwout bearing arm, noting the direction of the bearing and it mounting in the arm.

21.) Install the bell housing. Torque to specs according to the shop manual.

22.) Reinstall the clutch cable by prying on the throwout bearing arm. Replacement of the stock cable or quadrant is recommended if you haven’t already done so. With adjustable cables, both nuts go on the back side of the throwout bearing arm.

End of clutch replacement steps

23.) Install the transmission, have the transmission jack or helper at hand to lift it into place. Watch out that the stub of the shifter does not tear the shifter boot. Some transmission mount bolts with the heads cut off can be used to help support the transmission as you slide it home. It may be necessary to press the clutch pedal to get the transmission to slide the last ½” or so. Remove the guide studs if you used them & torque to specs according to the shop manual.

24.) Reinstall the rear crossmember & transmission mount. Torque to specs according to the shop manual.

25.) Reinstall the wiring and speedo cable or VSS sensor if you removed it.

26.) Reinstall the drive shaft, slide the yoke in place. Align the rear yellow markings and install the bolts. A helper to step on the brake to keep the drive shaft from turning will be helpful. Use your foot to apply pressure to the wrench to tighten the bolts.

27.) Remove the jack from under the engine oil pan.

28.) Refill the transmission with the proper fluid. T5’s use Dextron ATF, Tremec 3550’s use GM Synchromesh. There is a pair of pipe plug filler ports on the side of the transmission. Use the top plug as the filler port.

29.) Adjust the clutch cable according the manufacturer’s instructions if you have an adjustable cable & quadrant. Set the emergency brake and use the drag it provides in order to determine where the clutch starts to engage. You should have 1 -1 ½” free play from the top. The cable will not have any slack and will have some preload on it when properly adjusted.

30.) Re-install the H pipe and remaining items.

31.) When you have visually checked all the bolts, fittings and other parts are present and not interfering with each other, then take the car down off the jack stands.

32.) Be prepared to put the car back up on the jack stands to adjust the clutch and tighten up any loose items found after the test drive…

If you have a T5, you may be able to remove the trans & re-install it if you can bench press the 75 lbs that it weighs. If 75 lbs is too heavy, don't hurt yourself, get a trans jack. If your car has a Tremec 3550 or TKO, you will need a helper or trans jack because it weighs 100 + lbs. I built a trans jack from 2x2 angle iron, some swivel casters, 2x4's, 2x6's and a cheap floor jack. PM me if you are interested & I will send you the photos (8 MB) with the write up.

While you are at it, replace the stock cable & quadrant if it is still present. My choice for clutch & quadrant for street use:

Ford Racing M-7560-A302N - Ford Racing Clutch Kits - Overview - SummitRacing.com Ford Racing M-7560-A302N king cobra clutch kit $215-$259

Ford Racing M-6375-B302 - Ford Racing Flywheels - Overview - SummitRacing.com flywheel, cast iron $92

New items – the King Cobra clutch kit may not be in stock, so here’s the replacement:

http://www.summitracing.com/parts/F...ilter=1&query=Part+Type|Throwout+BearingsFord Racing clutch kit #FMS-M-7560-E302, $25, no throwout bearing included with the kit.

http://www.summitracing.com/parts/FMS-M-7548-A/ Ford Racing throwout bearing FMS-M-7548-A $52.

The quadrant needs to be replaced if you use any type of aftermarket cable or adjuster. My preference is a Ford Racing quadrant, adjustable cable and Steeda firewall adjuster. The adjustable Ford Racing cable is just a good as the stock OEM cable. It allows a greater range of adjustment than a stock cable with a aftermarket quadrant and firewall adjuster. Combined with the Steeda adjuster, it lets you set the initial cable preload and then fine tune the clutch engagement point to your liking without getting under the car.

Using a stock OEM cable and a single hook quadrant may result in not having any free pedal travel before the clutch starts to disengage. I found this out the hard way.

See Summit Racing - High Performance Car and Truck Parts l 800-230-3030 for the following parts.

Ford Racing M-7553-B302 - Ford Racing V-8 Mustang Adjustable Clutch Linkage Kits - Overview - SummitRacing.com Cable and quadrant assembly $90

Steeda Autosports 555-7021 - Steeda Autosports Firewall Cable Adjusters - Overview - SummitRacing.com Steeda firewall adjuster. $40

Fix for the quadrant end of the cable popping out of the quadrant when installing a replacement cable courtesy of Grabbin' Asphalt

Every time I get to that last 1/2 inch or so, I have to place a jack under the oil pan and ever so lightly lift the engine a fraction of an inch. That angle change is usually all it takes for it to slide right in.

Joe

Joe

Spaz

Member

I just did this. Mine also was difficult getting in the last inch or so. (I wish I knew about someone pressing the clutch pedal making it easier.) I got lucky, and after trying for awhile, on one try it just went right in. The time it went in easily there was hardly any force on my part. I was like, "Man that was easy, why didn't it do that 30 minutes ago?" But now I can definitely see how to answer your 1st question, yes, you do want the cable hooked up to the clutch fork.

Similar threads

- Replies

- 4

- Views

- 348

- Replies

- 26

- Views

- 1K

Paint and Body

DIY undertray thread

- Replies

- 34

- Views

- 2K

- Replies

- 0

- Views

- 178

- Replies

- 0

- Views

- 453