Since you are not familiar with how A/C works, here some background theory:

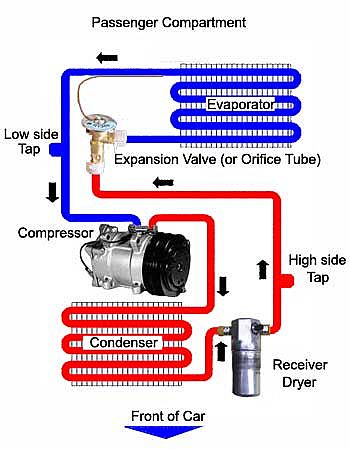

The condenser is up front of the radiator, and it is supposed to condense the hot gas from the compressor into a hot liquid. The hot liquid goes to the expansion valve located in the tubing next to the firewall. The expansion valve lets the hot liquid expand and become a cold gas, the cold gas goes to the evaporator inside the car where the fan blows on the evaporator exterior. The heat transfer from the air inside the car to the cold gas inside the evaporator causes the A/C to blow cold air. The now cool gas goes to the compressor where it gets compressed again into a hot gas and the process starts all over again. Keep in mind that this is a closed system, and the gas inside the A/C doesn't get out unless there is a leak, which is where you are at.

Typical automotive A/C system. This is similar to the Fox body A/C but the receiver/dryer on the high pressure side has been replaced by an accumulator/dryer on the low pressure side.

Here's where the problem gets sticky. All the original fox body Mustangs were made to use R12 refrigerant. R12 is no longer available unless you have an EPA 609 license or ignore the law and buy it off eBay. That means the system needs to be converted to use R134. Putting R134 on top of R12 without doing a proper conversion will cause compressor failure and metal from the compressor will circulate throughout the system. When this happens, it requires an extensive and expensive flush of the A/C system to get all the metal and other contaminants out. Skip doing the flush and clean thing and the new compressor will quickly fail.

When a R134 conversion is done, the installer is supposed to replace the service fittings with R134 style quick connector couplings.

Typical low pressure side R134 coupling

Typical high pressure side R134 coupling

[/color]

Then he places a R134 conversion sticker on the car. The typical sticker looks like this, yours may be different.

They are also supposed to replace all the O rings with R134 compatible O rings. The R134 gas molecule is smaller than the R12 molecule, so R12 O rings will be prone to leakage.

If the gas leaks out, usually it is because one of the O ring seals is bad. High quality R134 conversion is supposed to include new green O rings for all the joints and couplings. When you open the system to replace the O rings, all of the refrigerant must be removed and recovered and the system vacuumed down prior to recharging.

R134 recharge kits with refrigerant/leak detector dye can are available at most auto parts stores. Some of the R134 refrigerant refills have a leak stop in them.

BUT beware! The stop leak can block the expansion valve, causing system failure. The refrigerant/dye recharge kits are popular because the green dye makes a very visible indicator where the leaks is. Some of the recharge kits include a pressure gauge so you have some idea of how much refrigerant is in the system while it is running.

Try eBay for some R12, it is running $20-$30 a can. You need 3 each 12 oz. cans and 6-8 oz. of R12 compatible mineral oil. The R12 compatible oil is like $20 a quart when you can find it. You may be able to find a combination can of R12 and oil together which may be cheaper than buying a quart of oil..

It is illegal for a company to sell any refrigerant other than R134 to a person who does not have an EPA 608 or 609 certification. That includes Freeze 12. However, individual sellers like those on eBay and, not affiliated with a store often do not ask for any certification information, they just want prompt payment.

See

http://www.epa.gov/Ozone/title6/608/overlap.html for more details

R134a Air Conditioner Conversion and recharge instructions

Revised 14-Jul-2013 to add Low Pressure Cutout Switch adjustments for R134 & Freeze 12

Color Legend:

R134 specific items and instructions are in red text

Freeze 12 specific items instructions are in orange text

Note: R12 is available on eBay. Use the Freeze 12 instructions except use the R12 36 oz refrigerant charge with R12 refrigerant

Items and instructions common to both R134 and Freeze 12 are in black text

Tools and materials you will need:

Gauge set for recharging = $20-$120 – check out the pawn shops for a bargain before you pay retail.

See

Harbor Freight Tools for an inexpensive gauge set.

Vacuum pump – I use an old refrigerator compressor = $20- $40 at used appliance stores, or go to the Dump and get one for free. Be sure to have some R12 compatible oil handy to keep it lubed up properly.

O ring seal kit = $8.

Replacement accumulator/dryer assembly with hose $55-$75

Alternative refrigerant – Freeze 12 – it will allow you to skip flushing the system and reuse the original accumulator/dryer under certain conditions:

1.) If the A/C system has not been open to air for more than an hour or so.

2.) Or if it hasn’t out of refrigerant for more than 5-7 days and the system is till sealed up with no open or disconnected lines. You need to be able to hear the hiss when depress the valve core in either one of the service ports. That tells you that there is still pressure in the system, which keeps out moisture and contaminants.

If either of the above is not true, you must replace the accumulator/dryer assembly.

Freeze 12 refrigerant: $15-$16 per 12 Oz can on eBay. Get 3 cans, 2 for the initial charge and 1 spare for a top off charge.

Use R12 compatible mineral oil, 6-8 Oz. This may be difficult to find or expensive (~$20 a quart). Sometimes eBay will have the oil/R12 combination cans, which have about 4 oz. R12 and 2 oz. oil in them. If you go this route, add the R12/oil charge first, then add the cans of R12.

Do not use PAG oil in a Freeze 12 system without flushing it first.

Freeze 12 refrigerant charge= 26-28 Oz plus 6-8 Oz R12 mineral oil on an empty system. A recharge may only require 2-4 OZ of R12 mineral oil if you only replaced a line, hose or seals.

A/C systems that have had a compressor failure must be flushed. Failure to do so will result in the floating trash left behind from the compressor failure destroying the replacement compressor.

R134a = $11-$16 a can – takes 2 cans.

R134a PAG or Ester compatible oil = $7-$12 for an 8 oz bottle .

Pump to force cleaning fluid through the system $20-$50 (may use compressed air to do the same thing).

R134a charging adapter = $13 (I cut mine up to use it with the R12 gauge set that I have had for a long time).

Plastic tools to disconnect refrigerant lines - 1/2" & 5/8" = $4 each.

Flushing agent - Discount Auto Parts has some flushing solvent in a 1 gallon plastic bottle - try that first. Or use Mineral spirits = $4-$5 a gallon, tetrachloroethylene =$5-$10 a gallon, takes 2 gallons of either one.

Miscellaneous hoses and fittings to adapt the flushing pump to the system, and the R134a adapter to the R12 gauge set = $15.

R134 Refrigerant charge is 26-28 Oz plus 6-8 Oz of PAG 100 oil.

R134 Conversion Instructions:

I did a R134a conversion on my 89GT, and used all stock parts. You will need to replace the dryer/receiver (about $75 if you get the one with the hose made as part of the unit), and should replace all of the rubber "O" ring seals as well. You will need to drain all of the oil out of the compressor and replace it with new R134a compatible oil.

R134 instructions (skip this if you use Freeze 12)

Keep in mind that to fulfill the requirements of the EPA, you are required by law to recover any refrigerant that still remains in the system. How (or wither or not) you accomplish this is up to you. Connect the charging gauge hoses to the service ports on the A/C (red gauge = high pressure, blue gauge = low pressure) and open the valves on the gauges to dump the remaining refrigerant (if any) into your "Freon recovery system", whatever it may be. Disconnect the charging gauges since you are finished with them until you are ready to fill the system with R134a. Next comes the nasty part – in order to get all the old oil out of the system, you will need to flush it with special flushing solvent, or mineral spirits (ok) or tetrachloroethylene (better, but may be hard to get). If you leave the old oil in place it will congeal and reduce the heat transfer in the condenser and evaporator (read that it won’t cool good) and possibly damage the compressor.

Disconnect the compressor and remove it from its mount to flush it with cleaning solvent. Pour about a cup of solvent into the suction port and turn the compressor center hub about 10 turns while shaking the compressor to move the solvent around inside the compressor sump. Drain the flushing solvent out and continue to turn the center hub by hand to force out any remaining solvent. Then fill it with oil: add about 6-8 oz of the new oil to the compressor large suction fitting. Turn the compressor center hub about 20 turns as you turn the compressor face up and face down to distribute the new oil inside the compressor. Catch and replace any oil that comes out of the compressor.

Connect the pump (I had an electric sump pump I bought for $20) to the hose from the high-pressure side of the compressor. Alternately, you could use compressed air to force the cleaning fluid through the system. I didn’t like to do this since compressed air has lots of moisture in it, which is death to A/C systems. Pump the cleaning fluid through the system and let it come out the hose that was attached to the old dryer/receiver. I used 2 gallons of mineral spirits and pumped it all through the condenser and evaporator. The expansion valve is located near the firewall in the high-pressure line of the evaporator, and may cause the cleaning fluid to trickle through the lines at a very slow pace. You may want to pump cleaning fluid through the evaporator and condenser separately to speed up the process.

All refrigerant types

Next comes the changing of all the old "O" rings so that the chances for leaks is minimized. The new R134 compatible O rings are green colored, so be sure that the replacement O rings are green. Use the plastic connector tools to separate the lines, place the extended collar part of the tool so that it faces the large part of the connector and push inwards: this expands the spring so that you can pull the tube apart. You may need a helper to push on the tool while you pull on the tubes to separate them. Install the new "O" rings: be sure to coat them with new oil when you put them in. Install the new dryer/receiver, refrigerant service port adapter on the compressor, add about more 4oz of oil to high pressure line and tighten up all the lines. You may have to add more oil when you do a system that has been flushed or new R12 installation. The total oil charge should be 6-8 oz. for all types of refrigerants. Close the hood, start the engine, let everything get warm under the hood, but don’t add the refrigerant or turn the A/C on. Connect the charging gauge hoses to the service ports on the A/C (red gauge = high pressure, blue gauge = low pressure) and open both valves, then connect the center hose to the vacuum pump. The purpose of this exercise is to heat up the system so that when you vacuum it all down (yes, you will need a vacuum pump- mine is an old refrigerator compressor), that all the air, vapor and moisture from the cleaning fluid vaporizes and is removed from the system. Vacuum it down for about 30 minutes, this should give you about 28" of vacuum or more inside the A/C system. I have a vacuum gauge "T" connected into the vacuum pump line so that I can accurately watch the vacuuming process. This is a good time to take a soda and sandwich break since it doesn’t go faster if you watch it.

the R134a service fittings on the system: the red goes on the high side and the blue on the low side. This will help others identify that a R134a conversion has been done on the system.

Typical low pressure side R134 coupling

Typical high pressure side R134 coupling

Charging instructions for all refrigerant types:

Remove the electrical connector from the dryer/receiver and jumper the two connections inside the wiring harness side of the connector together: this allows the compressor to engage in spite of low pressure/no gas in the system. Close both charging gauge valves, and then disconnect the center hose of the charging gauges from the vacuum pump and connect it to the refrigerant can tapper. Put the refrigerant can in the can tapper and screw it down with the can tapper valve closed, then open the valve. Loosen the hose at the center connection of the charging gauge set until the refrigerant squirts out: this purges the line of air and moisture. The refrigerant is added through the low pressure side of the system, so open the low pressure gauge valve to add the refrigerant. Start the car and take note of the idle speed, then set the idle speed up to about 1200-1500 rpm, and turn the A/C on inside and set the fan speed on high. Watch for the pressure on the low side to drop off as you are filling, and the refrigerant can will get warm and stay warm. This tells you the current can is empty and needs to be changed for a fresh one. Before you disconnect the can, be sure to close the valve on the refrigerant can tapper.

Watch the high side pressure on the charging gages and regulate the adding of gas to keep the high side pressure under 350 psi. You will probably need a fan in front of the car to keep the readings below 350 psi. I had to put the refrigerant can in hot water while I was charging the system with it, or else the can got so cold that it quit flowing. Use caution when you do this so that you don’t get water in the charging adapter when you change the cans.

R12 Pressures when charging is complete

When you have added the 32-36 oz. of gas, the high side will read about 250-300 psi and low side about 28-38 psi. No adjustments need to be made to the low pressure cutout switch.

Freeze 12& R134 Pressures when charging is complete.

When you have added the 24-28 oz. of gas, the high side will read about 250-300 psi and low side about 18-28 psi.

Freeze 12& R134 Low pressure cutout switch adjustment.

The low pressure cutout switches are adjustable. They should be set with the low limit about 18-21 PSI, the stock setting is about 25 PSI. Remove the wiring connector and there is a screw slot in between the connector pins. Turning it clockwise increases the trip pressure where it cuts off and counterclockwise decreases the trip pressure. I believe that each 1/4 turn counterclockwise lowers the cutoff pressure by 1 PSI.

After Charging refrigerant instructions, all refrigerant types

Turn the idle speed back to where it was, turn the A/C off, disconnect the charging gauges, and re-install all the caps on the service ports. Remove the jumper from the low pressure switch harness and plug it back on the switch connectors.

R134 only

Then put the R134a Service Sticker on, secure all the loose wiring on the system and you are done.

The typical sticker looks like this, yours may be different.

I hope it cools good, mine doesn’t get quite as cold as it used to driving around town.

Thanks go to WWW.ACKITS.COM for some of the graphics.

Check out their website for parts and the Auto AC Forum.

The above technical note is for informational purposes only, and the end user is responsible for any damages or injury. The end user bears all responsibility for proper recovery/disposal of any R12 refrigerant.

I have EPA 608 and EPA 609 MVAC certification. And yes, you can shortcut the process, but there are negative factors if you do. Sooner or later, something will cease to function like it should. Shoddy work is a time bomb ticking away, waiting to explode.