Wow....

Several days spent working on the car, and not really one thing to talk about. Will that stop me from telling you about it?....hell no.

The Wiring phase has proven to be more spinning my wheels, and "this has gotta happen before that can" even more so than the dash.

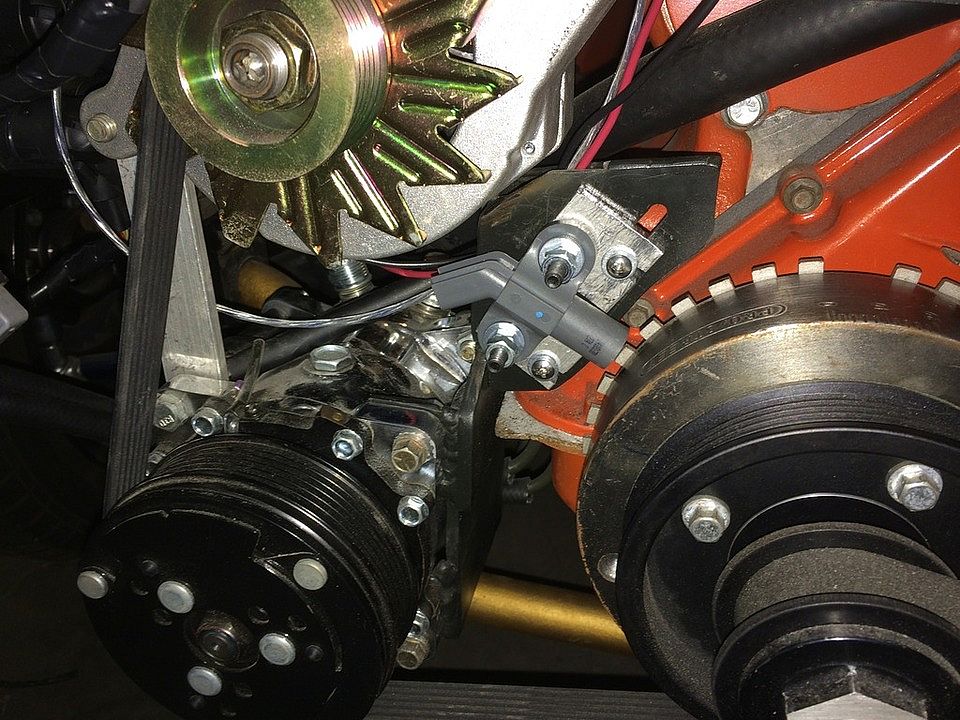

Take the crank trigger into consideration:

I don't know where I got the VR sensor. It's been so long since I bought the thing. Now that I'm at a stage where it matters, that has become an issue. EDIS uses a 2 wire VR sensor. The one I bought has three. EDIS is analog, My 3 wire crank sensor is digital. (I think). Consequently, it won't work. The actual crank sensor that is supposed to go with that is different to the point that it would require a complete redesign of the mount. (I'm not feeling that)

So knowing that I have another MSD two wire sensor in some drawer, I start grubbing around till I find it. Success! The good part is that it almost fits the hole that the old sensor was in. All I had to do was run a tap through the hole (cause the MSD sensor body is threaded) and I'll be good.

Did this solve the problem?

Nope.

See this is the way I go about doing things:

Shoot first, ask questions later.

The question I should asked myself

first was: What is different from the way an MSD crank trigger works from the factory EDIS system?

Instead, I

shot outta the garage, and bought the 20.00 3/4-16 tap to tap that hole, and make the MSD sensor fit.

Had I done it the "prudent" way, I would've known that MSD uses a system they called "flying magnet" where four magnets are placed at 90 degree intervals on the trigger wheel. So in essence, the MSD trigger is looking for a magnet to come whizzing by to trigger a

MSD computer to fire the specific cylinder.

The Ford sensor

is a magnet. It's looking for a single, big assed gap to tell the factory EDIS box, to fire the cylinder.

Bottom line, I gotta source the correct sensor, and rebuild the mount to accommodate it.

I tell ya, I'm my own worst enemy.

And true to form, I get to thinking about what kind of provisions are needed from the ECU (that I built from a kit) to do what, and when I want it to to turn water pumps, and cooling fans on and off based on coolant temp. So I get to looking back at the ECU that I built last December 2013.

Did I make the proper alterations/modifications so that I could control those events in programming?

Nope, didn't think about that either.

So I opened ol' dude back up.

I do some research, and add the necessary jumpers so that I will be able to tell the ECU if and when to turn the water pump and fan on. Then I open the can of worms.

And it spills out all over the table.

See, I also bought the megasquirt electronic boost control solenoid kit at the same time. But because I could not find a set of instructions (that made sense to me) at the time, I postponed adding the necessary circuitry to make that happen. Now that I had the ECU open, I was damn well gonna do it now. And for the next 8 hours, struggle trying to understand a simple three circuit, 4 wire mod. I finally went to bed at 2AM. Still needing to e-mail MSII tech to ask a question.

The stupid expensive steering wheel comes in, so I hop right to installing it. It was supposed to 1.5" bigger in diameter than the old wheel, in

actuality it was only an inch. It was supposed to work with the 60.00 spacer hub that was currently on the column, in

actuality, it used a standard Grant steering wheel adapter (which I had).

So, lets take inventory of what I accomplished by this swap:

The wheel needed to be bigger to allow me to see the gauges better. This one was one inch bigger.:tu:

However, the fact that I lost almost 2" of spacing puts the wheel that much closer to the gauge pod. I probably have lost visibility.:ughdown:

I wanted something different. Something classier than what I have ever had before.

While it's "classier" than any wheel I had before, is it that much different?

Nope.

How happy am I about that?

How happy do i look?

The boost gauge came in. It's better than the Cyberdyne that i sent back. I remove the center trim ring from the main gauge pod, and paint it. Then for the next 8 hours cannot touch it w/o leaving a finger print. I don't know what in the hell kinda paint I'm buying, but I don't want to have to wait till tommorrow to assemble a simple gauge trim ring because it has a week long cure time after painting. Never had paint from a rattle can take so long to dry.

I wiped off the paint (along with my finger prints) and am waiting till Monday to buy some stinkin' paint that'll be dry in a couple of hours, rather than 24.

So that's about it.Last three days wasted. Nothing but a wheel that looks like the one I use to have, a boost ga. installed, and a VR sensor (that I don't even have) that still needs to be fitted.