Hi. I'll try to keep it short but this may be important info. 83 gt has sat for the last 11 or 12 years, I finally got around to pulling the engine to do some work to it a few months back. Now I'm in full effort to get it on the road since I have nothing. Have done as minimal as needed to get it on the road the best I can. Only thing keeping it from driving is water pump and thermostat and clutch cable... The clutch cable was fine until putting the motor back in the car (transmission was left in the car) I didn't see or hear how but the. clutch cable got bumped off the shift fork during putting the motor back in. I put the cable back on and it slipped horribly

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi Everyone, Clutch Cable Question

- Thread starter 83-gt-hatch

- Start date

-

Sponsors (?)

I can't see any evidence of damage to the shift fork or the pedal. I've never messed with a clutch cable before so I assumed it was broken. I bought a new cheap cable and put it in. The outer sleeve is to short on the cable by like 3/4 inch. The cable reaches if I go around the bell housing but that obviously won't work to drive it. The new cable slips less but to bad to drive it. I still have the original (assuming what Ford put in it in 83. Only 140k miles on car) which is shorter then the new one in total length. Any ideas how to getone of those to reach? The original worked great before iI pulled the motor. I just see no damage anywhere to prevent it from being operational

Clutch adjustment

Do the clutch adjustment first before considering any other problems. With the stock plastic quadrant and cable, pull up on the clutch pedal until it comes upward toward you. It will make a ratcheting sound as the self adjuster works. To release to tension of the stock quadrant, use a screwdriver to lift the ratchet paw up and out of engagement with the quadrant teeth.

A binding clutch cable will make the clutch very stiff. If the cable is misrouted or has gotten too close to the exhaust, it will definitely bind. The binding common to adjustable cables is often due to misplacement of the adjusting nuts on the fork end of the cable. This will also cause the cable to wear and fray. Both nuts should be on the back side of the fork so that the domed nut faces the fork and the other nut serves as jam or locknut to the domed nut.

Clutch pedal adjustment with aftermarket quadrant and cable: I like to have the clutch completely disengaged and still have about 1.5” travel left before the pedal hits the floor. This means that I have only about 1” of free play at the top before the pedal starts to disengage the clutch. Keep in mind that these figures are all approximate. When properly adjusted, there will not be any slack in the clutch cable. You will have 4-15 lbs preload on the clutch cable.

Adjustable clutch cable tips:

Loosening the cable adjustment nut (throwout bearing arm moves to the rear of the car) moves the disengagement point towards the floor.

Tightening the cable adjustment nut (throwout bearing arm moves to the front of the car) moves the disengagement point towards the top of the pedal.

Firewall adjuster tips

Turning the firewall adjuster IN makes the engagement point closer to the floor since it loosens the cable. You have to push the pedal to the floor to disengage the clutch. Too loose a cable and the clutch won't completely disengage and shifting will be difficult. Gears will grind and you may have difficulty getting the transmission in first gear when stopped.

Turning the firewall adjuster OUT makes the engagement point farther from the floor since it tightens the cable. You push a short distance to disengage the clutch. Too tight a cable will cause clutch slippage.

Aftermarket solutions to the problem:

The quadrant needs to be replaced if you use any type of aftermarket cable or adjuster. My preference is a Ford Racing quadrant, adjustable cable and Steeda firewall adjuster. The adjustable Ford Racing cable is just as good as the stock OEM cable. It allows a greater range of adjustment than a stock cable with a aftermarket quadrant and firewall adjuster. Combined with the Steeda adjuster, it lets you set the initial cable preload and then fine tune the clutch engagement point to your liking without getting under the car.

Using a stock OEM cable, firewall adjuster and a single hook quadrant may result in not having any free pedal travel before the clutch starts to disengage. I found this out the hard way.

See Summit Racing - High Performance Car and Truck Parts l 800-230-3030 for the following parts.

Ford Racing M-7553-B302 - Ford Racing V-8 Mustang Adjustable Clutch Linkage Kits - Overview - SummitRacing.com Cable and quadrant assembly $90

The Ford Racing Adjustable cable is available as a separate part:

Clutch Cable, Adjustable, Ford, Mercury, 5.0L, Kit

[url=http://www.summitracing.com/parts/SDA-555-7021/]Steeda Autosports 555-7021 - Steeda Autosports Firewall Cable Adjusters - Overview - SummitRacing.com Steeda firewall adjuster. $40

http://www.steeda.com/images/watermarked/1/detailed/7/ford-racing-mustang-v8-and-v6-topside-clutch-adjuster-79-04-161-m-7554-a.jpg

Fix for the quadrant end of the cable popping out of the quadrant when installing a replacement cable courtesy of Grabbin' Asphalt

Help for those who have replaced the clutch assembly and are still having problems with adjustment:

The next step doesn't make much sense it you already have the transmission installed, but just for sake of discussion, here it is:

The throwout bearing sits in the clutch fork arm with the wave springs pressing on the rear flange of the throwout bearing.

Major differences between the distance between the flywheel surface and the clutch fingers may require tinkering with the clutch fork pivot ball. Stack your old pressure plate, clutch disc and flywheel up like they were when installed in the car. Tighten down all the pressure plate bolts and measure the distance between the clutch fingertips and the flywheel face.

Too much thickness will cause the clutch fork arm to sit too far back to get the clutch cable on the quadrant. It may even sit against the rear or the bell housing hole for the clutch fork arm. In that case, reduce the pivot ball height.

Too little thickness will cause the clutch fork arm to sit too far forward and bottom out against the front side of the bell housing hole for the clutch fork arm.. This will prevent the clutch from fully disengaging.

In other words, the clutch fork arm should sit positioned midway or a little towards the rear in the bell housing hole for the clutch fork arm when the cable is properly tensioned.[/url]

Do the clutch adjustment first before considering any other problems. With the stock plastic quadrant and cable, pull up on the clutch pedal until it comes upward toward you. It will make a ratcheting sound as the self adjuster works. To release to tension of the stock quadrant, use a screwdriver to lift the ratchet paw up and out of engagement with the quadrant teeth.

A binding clutch cable will make the clutch very stiff. If the cable is misrouted or has gotten too close to the exhaust, it will definitely bind. The binding common to adjustable cables is often due to misplacement of the adjusting nuts on the fork end of the cable. This will also cause the cable to wear and fray. Both nuts should be on the back side of the fork so that the domed nut faces the fork and the other nut serves as jam or locknut to the domed nut.

Clutch pedal adjustment with aftermarket quadrant and cable: I like to have the clutch completely disengaged and still have about 1.5” travel left before the pedal hits the floor. This means that I have only about 1” of free play at the top before the pedal starts to disengage the clutch. Keep in mind that these figures are all approximate. When properly adjusted, there will not be any slack in the clutch cable. You will have 4-15 lbs preload on the clutch cable.

Adjustable clutch cable tips:

Loosening the cable adjustment nut (throwout bearing arm moves to the rear of the car) moves the disengagement point towards the floor.

Tightening the cable adjustment nut (throwout bearing arm moves to the front of the car) moves the disengagement point towards the top of the pedal.

Firewall adjuster tips

Turning the firewall adjuster IN makes the engagement point closer to the floor since it loosens the cable. You have to push the pedal to the floor to disengage the clutch. Too loose a cable and the clutch won't completely disengage and shifting will be difficult. Gears will grind and you may have difficulty getting the transmission in first gear when stopped.

Turning the firewall adjuster OUT makes the engagement point farther from the floor since it tightens the cable. You push a short distance to disengage the clutch. Too tight a cable will cause clutch slippage.

Aftermarket solutions to the problem:

The quadrant needs to be replaced if you use any type of aftermarket cable or adjuster. My preference is a Ford Racing quadrant, adjustable cable and Steeda firewall adjuster. The adjustable Ford Racing cable is just as good as the stock OEM cable. It allows a greater range of adjustment than a stock cable with a aftermarket quadrant and firewall adjuster. Combined with the Steeda adjuster, it lets you set the initial cable preload and then fine tune the clutch engagement point to your liking without getting under the car.

Using a stock OEM cable, firewall adjuster and a single hook quadrant may result in not having any free pedal travel before the clutch starts to disengage. I found this out the hard way.

See Summit Racing - High Performance Car and Truck Parts l 800-230-3030 for the following parts.

Ford Racing M-7553-B302 - Ford Racing V-8 Mustang Adjustable Clutch Linkage Kits - Overview - SummitRacing.com Cable and quadrant assembly $90

The Ford Racing Adjustable cable is available as a separate part:

Clutch Cable, Adjustable, Ford, Mercury, 5.0L, Kit

[url=http://www.summitracing.com/parts/SDA-555-7021/]Steeda Autosports 555-7021 - Steeda Autosports Firewall Cable Adjusters - Overview - SummitRacing.com Steeda firewall adjuster. $40

http://www.steeda.com/images/watermarked/1/detailed/7/ford-racing-mustang-v8-and-v6-topside-clutch-adjuster-79-04-161-m-7554-a.jpg

Fix for the quadrant end of the cable popping out of the quadrant when installing a replacement cable courtesy of Grabbin' Asphalt

Help for those who have replaced the clutch assembly and are still having problems with adjustment:

The next step doesn't make much sense it you already have the transmission installed, but just for sake of discussion, here it is:

The throwout bearing sits in the clutch fork arm with the wave springs pressing on the rear flange of the throwout bearing.

Major differences between the distance between the flywheel surface and the clutch fingers may require tinkering with the clutch fork pivot ball. Stack your old pressure plate, clutch disc and flywheel up like they were when installed in the car. Tighten down all the pressure plate bolts and measure the distance between the clutch fingertips and the flywheel face.

Too much thickness will cause the clutch fork arm to sit too far back to get the clutch cable on the quadrant. It may even sit against the rear or the bell housing hole for the clutch fork arm. In that case, reduce the pivot ball height.

Too little thickness will cause the clutch fork arm to sit too far forward and bottom out against the front side of the bell housing hole for the clutch fork arm.. This will prevent the clutch from fully disengaging.

In other words, the clutch fork arm should sit positioned midway or a little towards the rear in the bell housing hole for the clutch fork arm when the cable is properly tensioned.[/url]

That is alote of info. I'm on my 3rd time reading it. As far as I can tell neither the new or the original are adjustable. What gets me is the original worked perfect before it popped off. It's a stage 2 clutch and never a problem. I can't say there is any binding since the pedal feels right. I'm not driving it except for test rides type trips so I don't burn up the clutch in the process. Aside from it not disengaging all the way leading to some major slipping

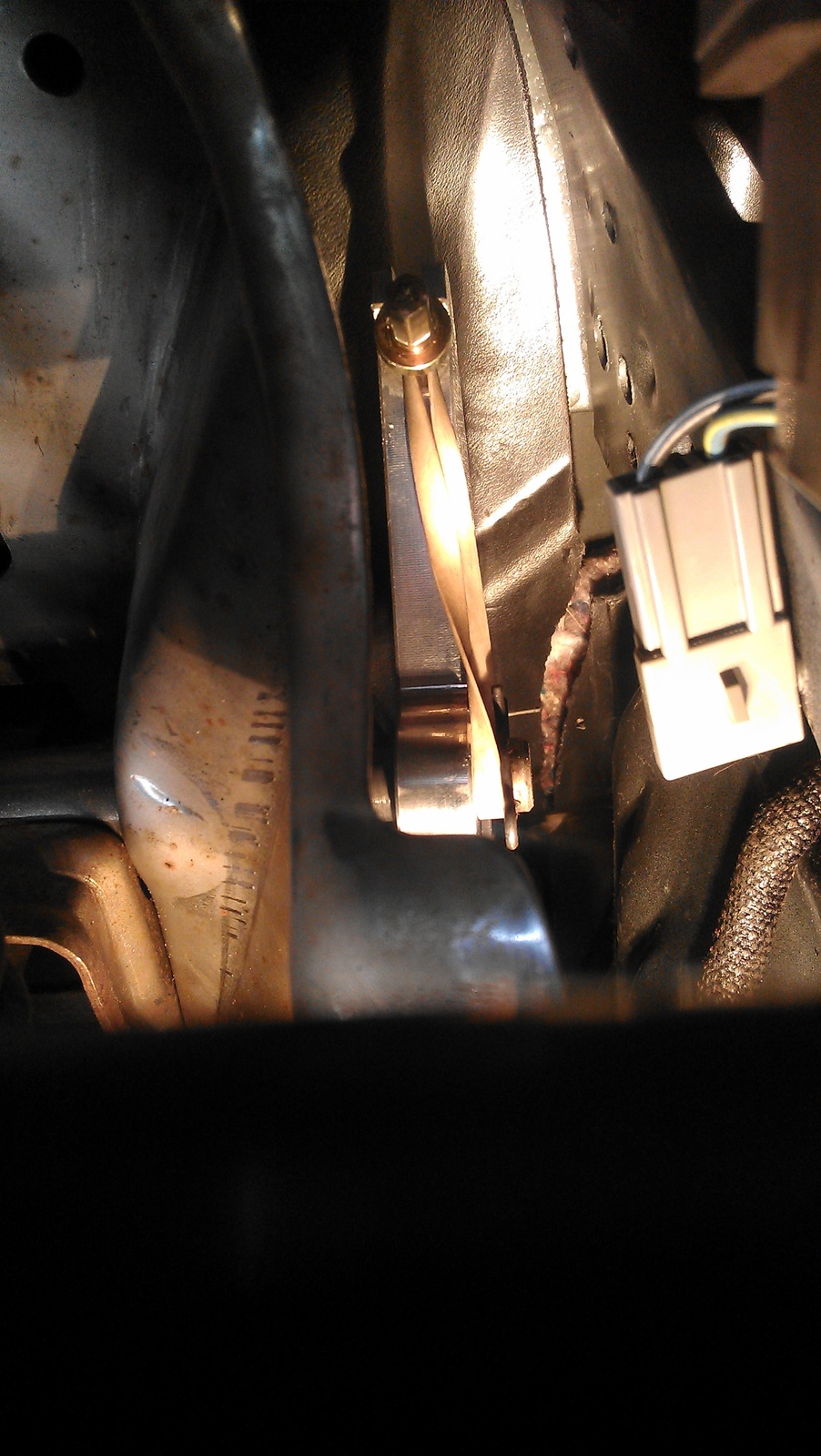

That is alote of info. I'm on my 3rd time reading it. As far as I can tell neither the new or the original are adjustable. What gets me is the original worked perfect before it popped off. It's a stage 2 clutch and never a problem. I can't say there is any binding since the pedal feels right. I'm not driving it except for test rides type trips so I don't burn up the clutch in the process. Aside from it not disengaging all the way leading to some major slippingSorry I'm still getting used to this forum and my phone isn't getting along with this site that great.. Before the original cable popped off and prior to the motor pulled out the clutch operated perfectly leaving traction the problem. If I put the original back on it is worse then the new cheap one. As you can tell in the picture I don't have nuts at the fork for adjustment. It just pops into the hole in the fork

Aside from the slipping it drives nice. Just need that extra 3/4 inch or so. The width of the bell housing to get it where it needs to be. A little more would be great but not needed. I like your idea of having that extra inch. Don't need it though

I did call ATP(brand of cheap cable I bought) and they said it's not adjustable and it may be a defective part. I'm taking tonite off but I plan to swap back to the original tomorrow. I read in the chilton's about the self adjusting part and quick instructions how (lift pedal all the way up then pushing down all the way) I didn't try that before getting the new cable. Since I didn't know about that. I plan to try that tomorrow. With the original cable.

I just don't see why a cable that looks good and not broken like I thought that had worked on the car for years and years all the sudden had became too short

@83-gt-hatch

I guess that you don't understand that there is a self-adjusting mechanism for the clutch cable. As the clutch wears the cable tension changes, that is why there is a self-adjusting mechanism built into the clutch pedal. There is a toothed plastic quadrant with a ratchet pawl that engages the quadrant ratchet teeth. As you pull up on the clutch pedal, it ratchets and takes any slack out of the clutch cable. Mess around with the pedal or even bump it while the end that fits in the clutch fork is loose, and it tries to take up the slack in the cable. That has the effect of shortening the cable.

You can use a screwdriver to lift the ratchet pawl off the quadrant teeth. That will allow you to move the quadrant to allow more slack in the cable. If the cable is too loose, pull up on the pedal. The ratchet pawl will allow the quadrant to take up the slack in the cable and lock the adjustment.

Adjustable cables are used when the plastic quadrant is replaced with an aftermarket metal quadrant. The downside to this setup is that you have to get under the car to adjust the clutch. Add a firewall adjuster to an adjustable cable setup and you can spare yourself from getting back under the car to make any fine adjustment that you desire.

The fancy 2 and 3 hook aftermarket metal quadrants are for use with stock length cable and a firewall adjuster. Use the firewall adjuster and screw in and out to take the slack out of the cable and get the clutch engagement point just where you want it.

I guess that you don't understand that there is a self-adjusting mechanism for the clutch cable. As the clutch wears the cable tension changes, that is why there is a self-adjusting mechanism built into the clutch pedal. There is a toothed plastic quadrant with a ratchet pawl that engages the quadrant ratchet teeth. As you pull up on the clutch pedal, it ratchets and takes any slack out of the clutch cable. Mess around with the pedal or even bump it while the end that fits in the clutch fork is loose, and it tries to take up the slack in the cable. That has the effect of shortening the cable.

You can use a screwdriver to lift the ratchet pawl off the quadrant teeth. That will allow you to move the quadrant to allow more slack in the cable. If the cable is too loose, pull up on the pedal. The ratchet pawl will allow the quadrant to take up the slack in the cable and lock the adjustment.

Adjustable cables are used when the plastic quadrant is replaced with an aftermarket metal quadrant. The downside to this setup is that you have to get under the car to adjust the clutch. Add a firewall adjuster to an adjustable cable setup and you can spare yourself from getting back under the car to make any fine adjustment that you desire.

The fancy 2 and 3 hook aftermarket metal quadrants are for use with stock length cable and a firewall adjuster. Use the firewall adjuster and screw in and out to take the slack out of the cable and get the clutch engagement point just where you want it.

Last edited:

- Mar 2, 2015

- 6,811

- 5,849

- 203

Above the gas pedal behind the dash (where the clutch cable enters the car) there is a whitish yellow plastic cable adjuster. When the cable slipped the adjuster adjusted all the way out... That's why the cable seems short.

- Mar 2, 2015

- 6,811

- 5,849

- 203

What I do is tie a string to the hook part of the quadrant below the spring on the pivot point. I then take a screw driver and release the triangular locking mechanism. Pull on the string tied to the hook part and tie it to the steering wheel. That way it'll hold the position so you can attach the cable to the clutch fork. Once in the clutch fork untie string and bam done. The best advice I can give is to buy an aluminum quadrant with a firewall adjuster..... The factory plastic ones usually end up breaking when you least expect it. Your cables are fine...

Thank you for your advice. I know what I have to do now. I didn't understand how the self adjuster worked. In the past with my old 85 ranger I learned all about a hydraulic clutch system. I didn't understand what all you wrote yesterday completely. The latter is explained to a easier understanding. When I put the motor back in and whatever bumped the cable off must have upset the quadrant pawl

Now the fun part of getting above the pedals and loosen it back to where it's too loose to get it right. I'm still going to put the original cable back on and do what you two told me and loosen it at the quadrent pawl and go from there. I'm crawling under now. I will update you soon and let you know how it goes. Appreciate the help

Thank you very much for your help. Works like new again. It took a little time to find and get it to move. 10 times with the pedal tightening it up and works like a charm. Just got back from a test drive. It appears my overheating problem is from the vac advance hose. Messing everything up. I think after I tinker with that it's good to start driving it again. It's been since December 2003 since it's been driven. Aside from my 5 test runs leading to 11 miles before tonite. Thank you again. I hope one day I get the chance to lend you a hand (although it appears I am amateur compared to most of what I've seen in these forums)

- Mar 2, 2015

- 6,811

- 5,849

- 203

Glad it helped you out. I love these cars and have worked on a bunch of them. Now when you see someone having a cable problem you'll know what to do to help. See you're just like us.lol.

Lol. I've got alote more to learn. I've been trying to learn as I go over the years. Ive learned alote over the last 12 years since I've had my license. This mustang was my 2nd car. I got it 2 days before I got my license from a friend. The first Igot to drive everyday. Not to mention he was the one that taught me to drive a 5 speed on this very mustang. I fell in love with this car quickly. Along with mustangs in general. I've been offered 2 grand for it cash right now and turned it down. I've had a standing offer from a friend for the whole 11 years it's sat for 1500. This car had intemidated me over the years from working on it. But I have one of my dream cars sitting right here. Along with the 08 gt500 and the gt500kr. The 03 cobra 04 mach 1. Well you get the idea, I can keep going. I was wishing to do a restoration before I drove it again but been stuck living in positions that sometimes has to be elsewhere from the car and unable to work on it. I'm hoping that once it's driving by next month I should be doing well enough to do more much needed work and with a little luck are some point I can take it off the road and do a full restoration to it. It's got rough over the years.

- Mar 2, 2015

- 6,811

- 5,849

- 203

I got into mustangs through a friend of mine. My first one was an 87 hatch back 4cyl....we snatched the power booster out and threw a 460 and trans into it. Lol. That car was a fast POS. We didn't do anything else so the car was eventually twisted to shreds (didn't know any better). My 89 Vert was my favorite. Even with the ten point cage and sub-frame connectors it still met its demise ( rust in the strut towers and stress cracks in the cowl). The car ran strong 10.40s in the 1/4. The build I'm doing now on my coupe is a street build....450hp at the crank with cobra IRS... Not too many drag strip runs in my future...don't want to tear this one up.smh

Sounds like a nice build you have going on. I just want the glorified show car that has the power to roast em and get around traffic and the occasional boosted Honda that the driver talks to much. I estimate it has around 300hp or a little less now. Aside from my duel cone intakes I want to do in the future when it turns into a toy and not a daily driver. Duel cones under the bumper. Using the factory fender piping and actually a full exhaust not the rigged system I got now. But u want to rebuild the motor nice, get it freshened up and clean up the motor bay alote. New wiring the whole 9 yards. Replace the metal behind the rest quarters where it's rusted out. Freshen up the interior (it'd not in bad shape but does have a big tear in the back seat and driver seat shows wear and the dash pad is cracked) and some fresh paint. I'm thinking to go with the black that you wanna walk into and the game boss style stripe coming off the hood in that new dodge ram green modified a little so it's not as gold. Svo tail lights and some better flowing heads

For now I'm just trying to get it on the road and stop taking the bus to work. It's got me stumped right now. Keeps pointing to the distributor vacuume advance sticking (not 100% sure how that operates) on a cold start it runs great and hasn't been overheating until that temptation moment to get on it a little. Then you'd swear the timing was off and it starts overheating. I've gone through the best I can with the vac hoses with what I have at the house before payday comes around. But when it runs horrible it runs great with high rpms. So for now it sits another week until I can get to my buddies house. Once on the road I still got plenty of work to get it right but nothing keeping it from driving. Keep improving on it and hoping to get another truck to give it a rest and keep improving

Similar threads

- Replies

- 1

- Views

- 618

- Replies

- 7

- Views

- 782

- Replies

- 11

- Views

- 1K

Progress Thread

2004 Comp Orange GT

- Replies

- 9

- Views

- 2K

- Replies

- 5

- Views

- 3K