Here's how it works, maybe this will help you understand the process better.

How the fuel pressure regulator works

Revised 5-Jan-2014 to add how to set fuel pressure,

Step 1.) Check fuel pressure:

The local auto parts store may rent or loan a fuel pressure test gauge if you don't have one.

Disconnect the vacuum line from the fuel pressure regulator. Check it for evidence of fuel present in the line by removing it and blowing air through it. If you find fuel, the fuel pressure regulator has failed. Reinstall the line; leave the fuel pressure regulator end of the vacuum line disconnected. Then cap or plug the open end of the vacuum line and us-mg6.mail.yahoo.com/stow it out of the way.

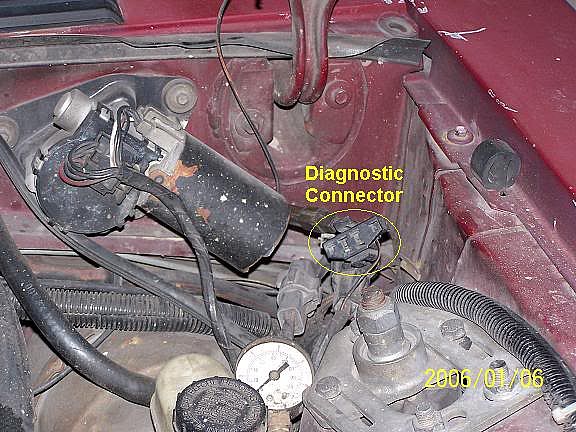

Connect the fuel pressure test gauge to the Schrader port located just behind the alternator.

Turn the ignition switch on & start the engine. Observe the pressure: you should see 37-41 PSI at idle.

Turn the ignition off; reconnect the vacuum line to the fuel pressure regulator. Then disconnect the fuel pressure test gauge. Watch out for squirting gas when you do this.

Step 2 .) How the fuel pressure regulator works

The fuel pressure regulator in 5.0 pushrod Mustangs is a shunt regulator that works in parallel with the fuel injection system. The regulator bypasses fuel back to the tank to maintain a constant 39 PSI to the injector tips. A constant pressure insures that the computer will always have the same flow rate to base its calculations on.

The 39 PSI pressure is measured at 29.92 inches of atmospheric pressure to get the proper flow rate. But the pressure inside the intake manifold may be higher or lower than the atmospheric pressure outside the intake manifold. These differences would cause the flow rate to change and mess up the computer’s air/fuel calculations.

As the vacuum inside the intake manifold increases, the effective pressure at the injector tips increases. Conversely, as vacuum inside the manifold decreases, the effective pressure at the injector tip decreases.

Some math to illustrate the effect:

39 PSI at 20” of vacuum inside the manifold works out to be 49 PSI,

since the 20 “ vacuum/2 = 10 PSI that you add to the base fuel pressure.

That gives you 49 PSI at the injector tip.

39 PSI at 5” of vacuum inside the manifold works out to be 41.5 PSI,

Since 5” vacuum/2 = 2.5 PSI that you add to the base fuel pressure

That gives you 41.5 PSI at the injector tip

39 PSI with 10 lbs of boost inside the manifold works out to be 29 PSI.

That gives you 29 PSI at the injector tip

That reduces the flow rate and explains the need for higher pressures on engines with pressurized induction.

Since intake manifold vacuum and pressure plays havoc with the pressure at the injector tips, what has to be done to get it back in the magic 39 PSI range? That’s where vacuum applied to the back side of the fuel pressure regulator comes in. Remember this: unless you have some really poorly designed or trick plumbing, vacuum is the same throughout the engine’s vacuum system.

Apply 20” of vacuum to the back of the regulator and the 49 PSI pump pressure with 20” of vacuum at the injector tips drops to 39 PSI.

Apply 5” of vacuum to the back of the regulator and the 41.5 PSI pump pressure with 5” of vacuum at the injector tips drops to 39 PSI.

Here’s another side effect: apply 10 PSI boost pressure to the back of the regulator and the normal 39 PSI at the injector tips increases to 49 PSI. That overcomes the 10 PSI in the intake manifold to give you 39 PSI at the injector tips. Pretty clever of these engineers to use intake manifold vacuum and pressure that way.

Simply stated, intake manifold vacuum adds to the effective fuel pressure at the injector tips. Apply the same vacuum to the back side of the fuel pressure regulator, and everything balances out. Add pressure to the intake manifold and the effective fuel pressure at the injector tip decreases. Apply the same pressure to the back side of the fuel pressure regulator, and everything balances out.

Now you know why to disconnect the vacuum when making fuel pressure measurements.

again. Maybe the pump is faulty. Im waiting for a fuel pressure gauge to see if im pulling 38psi at idle. Any help would be greatly appreciated [emoji106]

again. Maybe the pump is faulty. Im waiting for a fuel pressure gauge to see if im pulling 38psi at idle. Any help would be greatly appreciated [emoji106] again. Maybe the pump is faulty. Im waiting for a fuel pressure gauge to see if im pulling 38psi at idle. Any help would be greatly appreciated [emoji106]

again. Maybe the pump is faulty. Im waiting for a fuel pressure gauge to see if im pulling 38psi at idle. Any help would be greatly appreciated [emoji106]