This exactly, although 3/8 studs will be more than fine for a 500 hp build that will see less than 6500rpms IMHOAre you sure those are ARP studs? The AFR's are notorious for breaking their stock 3/8" studs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bang,bang,clang Clang!!!

- Thread starter smkshw

- Start date

-

Sponsors (?)

just read up how to adjust hydraulic lifters....think i can handle it...."seems" easier then my dirt bike actually......im going to go ahead and put 7/16 rockers in just to be safe

Should have it back on the road by the weekend i hope...im just a back yard mechanic so if you guys have any tips so i dont miss anything id appreciate it though....lol

Should have it back on the road by the weekend i hope...im just a back yard mechanic so if you guys have any tips so i dont miss anything id appreciate it though....lol

@84Ttop ,@RangerJoe

been reading and some ppl say 1/2 turn or full turn from 0 lash?........was thinking 1/2 then 1/4 to snug up?...what do use guys recommend?

been reading and some ppl say 1/2 turn or full turn from 0 lash?........was thinking 1/2 then 1/4 to snug up?...what do use guys recommend?

Why did you get all new rockers? You can purchase them individually. As far as how far to turn after zero lash, that should be specified in the instructions the rockers come with. There are lots of opinions out there but somewhere between a 1/4 min. to no more than 1 full turn after zero lash is what i've read. After zero lash the amount your turn is the amount of preload your putting on your lifters.

i upgaded to 7/16 rockers and studs....ya everyone seems to have different opinions...ill read what it says thenWhy did you get all new rockers? You can purchase them individually. As far as how far to turn after zero lash, that should be specified in the instructions the rockers come with. There are lots of opinions out there but somewhere between a 1/4 min. to no more than 1 full turn after zero lash is what i've read. After zero lash the amount your turn is the amount of preload your putting on your lifters.

Too bad i just saw this thread now cause after reading your first post i knew what it was and as i read further i was looking to see if someone was gonna ask sure they are ARP studs cause my guess was they werent Ranger Joe nailed that. I broke a AFR rocker stud also in my 185s so after i looked it up i found lots of threads saying they broke them too, as much as i love my AFR heads im surpised they never have upgraded them studs yet. You should be fine now after i upgraded to ARP studs no more problems that was bout 10k miles ago.

squeak93

15 Year Member

And to add to that when you do it initially it may feel to tight when all said and done. i rolled the motor past the stroke where i was setting that valve and rolled it back to the point of where you can adjust it and re checked it . And sure enough it felt like all the others feel at there correct adjustment.agreed on 1/2 turn past zero. Always used that and no issues.

ya well i learned my lesson....i thought arp was in there but only on the heads,too bad i didnt read about this before the build....now i went over kill with the 7/16 but i shouldnt have any issues now at least...Too bad i just saw this thread now cause after reading your first post i knew what it was and as i read further i was looking to see if someone was gonna ask sure they are ARP studs cause my guess was they werent Ranger Joe nailed that. I broke a AFR rocker stud also in my 185s so after i looked it up i found lots of threads saying they broke them too, as much as i love my AFR heads im surpised they never have upgraded them studs yet. You should be fine now after i upgraded to ARP studs no more problems that was bout 10k miles ago.

ya well i learned my lesson....i thought arp was in there but only on the heads,too bad i didnt read about this before the build....now i went over kill with the 7/16 but i shouldnt have any issues now at least...

yup i got that same lesson i didnt know AFR rocker studs were weak till i broke one then i did research, if i remember right there was a couple threads on corral about it. I have 25k on stroker now running real good last couple years its been just changing oil and couple little very minor things (knock knock on wood) BTW im running pro magnum rockers im pleased with and the ultras p m are even better.. good luck with her

I always tighten hydraulic rockers 1/4 turn past zero lash. Not saying that 1/2 a turn is too much but it's the way I was taught years ago. As long as you adjust the intake as soon as the exhaust valve starts to open and adjust the exhaust just after the intake starts to close you'll be fine

thanks,ya sucks i over looked that!...but im going to give her a go later today or tomorrowyup i got that same lesson i didnt know AFR rocker studs were weak till i broke one then i did research, if i remember right there was a couple threads on corral about it. I have 25k on stroker now running real good last couple years its been just changing oil and couple little very minor things (knock knock on wood) BTW im running pro magnum rockers im pleased with and the ultras p m are even better.. good luck with her

I go 1/2 turn....but I am just a novice at this. The issues with the AFR studs is that they are too short. Not enough threads catch and all the stress is put on the top of the studs. This is why they always break off up high and not at the base.

7/16 may be over kill, but you won't have to upgrade again.

Joe

7/16 may be over kill, but you won't have to upgrade again.

Joe

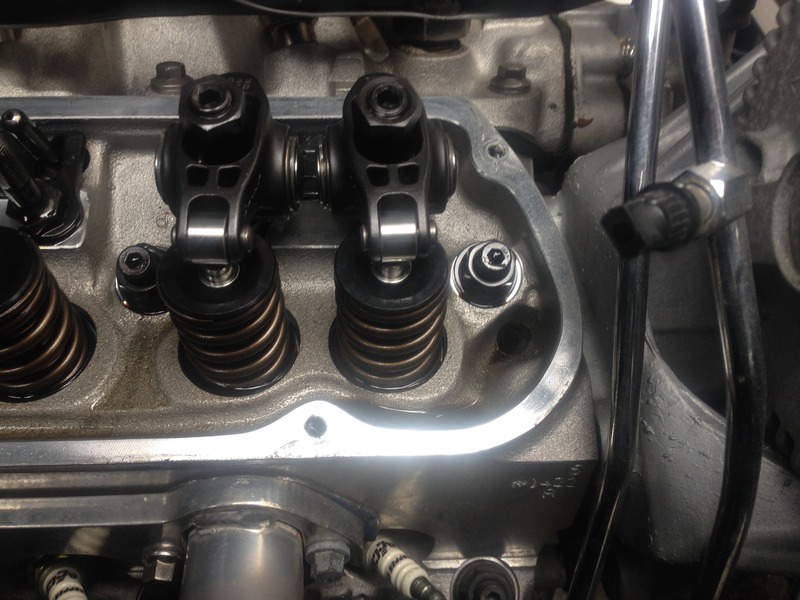

ok so i started and then stopped....these heads have the adjustable rocker stud plates,i was trying to align them the best i can but it keeps moving when i try to torque the studs?...so got it the best i can and held it with a flat head but they dont seem to alighn very well?...i tightend the rockers 1/2 passed 0 lash....

any tips guys?...the ones that are still on there seem the same way also?

any tips guys?...the ones that are still on there seem the same way also?

Nice choice on the rockers! Are you using a little moly lube underneath the base of the stud? That should help it turn a little bit. If I remember correctly, I had to adjust mine all a little differently. Also, I was advised to use thread sealant on the studs that are open into the ports (intake I think).

Joe

Joe

squeak93

15 Year Member

That rocker on the right looks out of alignment. I'd be afraid of causing undue stress on the spring and getting coil bind or breaking it. Use the moly trick listed above under the studs to tighten them to spec w/o binding the brackets/guide plates.

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 11

- Views

- 3K

- Replies

- 23

- Views

- 3K

Progress Thread

finishing touches on my stroker build

- Replies

- 22

- Views

- 3K