OK so finished up day 3 of the assembly process. Goal was to get the engine, transmission, rear axle,

suspension, steering and wheels on.

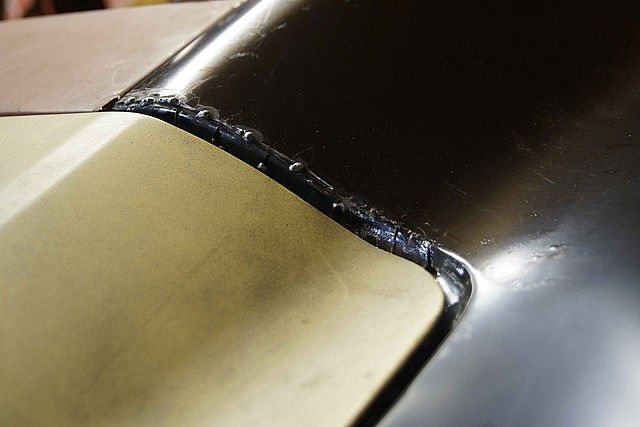

Everything went smooth and fast until the rear transmission bracket. I am installing a TKO600 low profile version from Modern Driveline. I am overall pleased with the product fit. The only issue was the transmission cross member bracket they made did not fit well at all. I ended up cutting and re-welding the bracket to fit. The bracket did not go back far enough by one inch.

The transmission fit in the middle of the shifter hole and I did not have to trim anything from the transmission tunnel. I have 1/2 inch clearance from the top of the transmission to the tunnel brace.

First day went fast. Unpacked all the boxes of parts I have accumulated. I used all new AMK bolts/fasteners specific/correct for early 67 mustang. I also used

suspension components from grab a trak - Mustangs plus - medium firmness. Engine has aluminum top end - I painted the heads for a more stock look.

Engine has a comp cam, stock rods/crank, edelbrock aluminum heads and intake. I used 1968 CJ exhaust manifolds mostly for stock look and ease in fitting the engine into a tight engine bay - which worked out well.

Rear axle is a 3.5 posi track with new 31 spline axles and all new brake internals.

Front is a new stock power disc brake setup.

Steering gear box rebuilt by Dan at Chokostang. I am going with an in the column electronic assist steering so I put a non-power steering set up in and used the old steering column for now - the interior has not been painted yet.

Wheels/tires are off an old project, I am eventually going with styled steels in a 15X7 configuration.

Now the car goes back to the restoration shop, they are almost ready to paint the hood, fenders, doors, decklid and other small parts. I will have them get those parts back on the car before I bring it home to work on getting her running and all the other stuff - interior, wiring, etc.

Day 1 (Monday) -Picked up car from the shop and transported to a friend's shop that has a lift. Installed front spindles, brakes, upper-

lower control arms, coil springs, rear leaf springs, rear axle, strut rods and front sway bar.

Day 2 (Tuesday) - Installed steering gear box, fuel and brake lines, emergency brake cable, Engine, clutch and TKO 600 transmission - except the rear tranny bracket.

Day 3 (Wednesday - Today!) - cut the transmission bracket, refit it multiple times and then welded it up and reinstalled. Rechecked all bolts on everything to make sure they were tight. Installed numerous other small items and fasteners.

Here are a few of the highlight photos.

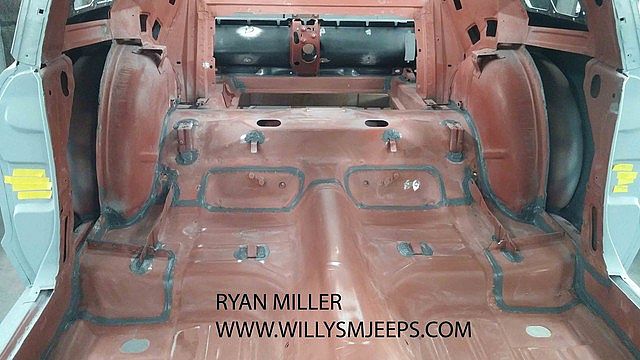

Day 1 after picking up the car - look familiar - same location I used when I took the car to be dipped for rust/paint as a bare shell. I am back to square one.

End of Day 1

Day 2

Just realized I forgot to take a photo of the shifter coming up through the transmission tunnel. Guess I was too tired to think about it tonight.