You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Life Span Of Iac / What Chews Them Up

- Thread starter TealVert

- Start date

-

Sponsors (?)

jozsefsz

15 Year Member

The IAC sensor gets dirty, and it's an electrical actuator that moves around quite a bit in response to load events. Electric motors wear out, especially cheap chinese ones (as are most things these days). Cleaning it is usually enough though, and I'd suspect something else with how fast you're going through them.

You might want to search this site for the base idle reset procedure before replacing the IAC again. The car should idle even with the IAC disconnected, since yours is stalling I'll assume it doesn't. As the throttle stop and pivot wears on the throttle body, there is less throttle body airflow, and the engine depends more on the IAC. That'll give you a hunting / surging idle and occasional stalling. The idle reset procedure will get that squared away.

Also check for vacuum leaks -- the way our PCV system is set up, all of the gaskets and seals in the engine are a vacuum leak waiting to happen. That and rotted 20+ year old vacuum lines (especially those pulling fuel vapors) can cause substantial leaks and idle issues as well. Ordinary tune-up items (plugs, wires, fuel filter, injector cleaning, O2 sensors) go without saying.

You might want to search this site for the base idle reset procedure before replacing the IAC again. The car should idle even with the IAC disconnected, since yours is stalling I'll assume it doesn't. As the throttle stop and pivot wears on the throttle body, there is less throttle body airflow, and the engine depends more on the IAC. That'll give you a hunting / surging idle and occasional stalling. The idle reset procedure will get that squared away.

Also check for vacuum leaks -- the way our PCV system is set up, all of the gaskets and seals in the engine are a vacuum leak waiting to happen. That and rotted 20+ year old vacuum lines (especially those pulling fuel vapors) can cause substantial leaks and idle issues as well. Ordinary tune-up items (plugs, wires, fuel filter, injector cleaning, O2 sensors) go without saying.

Thanks for the info. I will check out the thread. Plugs are not that old, fuel pump has been upgraded and filter was the first thing I changed. 02's are both new. Couldn't get the old ones out of the cat pipe anymore so the off road pipe has new ones. Have not touched the injectors. I will check on the vacuum lines next. It was my daily driver up until 2 years ago. I am convinced that once you stop driving them is when the stuff breaks.

That is a high rate of failure. They usually last a few years if not better. I figure you should get at least half a decade out of one. Be careful of cheap IACs from China. Also, I noticed you have a K&N filter. If you have cleaned it and re oiled, always make sure you blow out as much excess oil from the filter as possible after letting it dry. The K&N filter oil has a tendancy to get sucked in if it is in excess and can mess up the MAF and the IAC.

Kurt

Kurt

Well I tried the idle reset methode - HA! I couldn't even get the car to start with the idle control unplugged. Plugged it back in and the car came to life. It ran for about ten minutes with out issues. Two days later I used the car. I was stuck in traffic and It stalled every chance it could. Three pedals with two feet is a nightmare when trying to keep the car from stalling.

jozsefsz

15 Year Member

That's your stalling problem in a nutshell. Adjust the stop-screw until it actually does run with the IAC disconnected. You can also adjust the idle air bypass to give it more air (it's a hex-screw underneath the rubber plug on the throttle body).

The idle reset method requires you to start the car, warm it up, then disconnect the IAC. Use the throttle linkage to give it enough air to keep it running while you adjust the stop-screw and / or the idle air bleed. You'll eliminate the stalling if you complete the procedure correctly.

The idle reset method requires you to start the car, warm it up, then disconnect the IAC. Use the throttle linkage to give it enough air to keep it running while you adjust the stop-screw and / or the idle air bleed. You'll eliminate the stalling if you complete the procedure correctly.

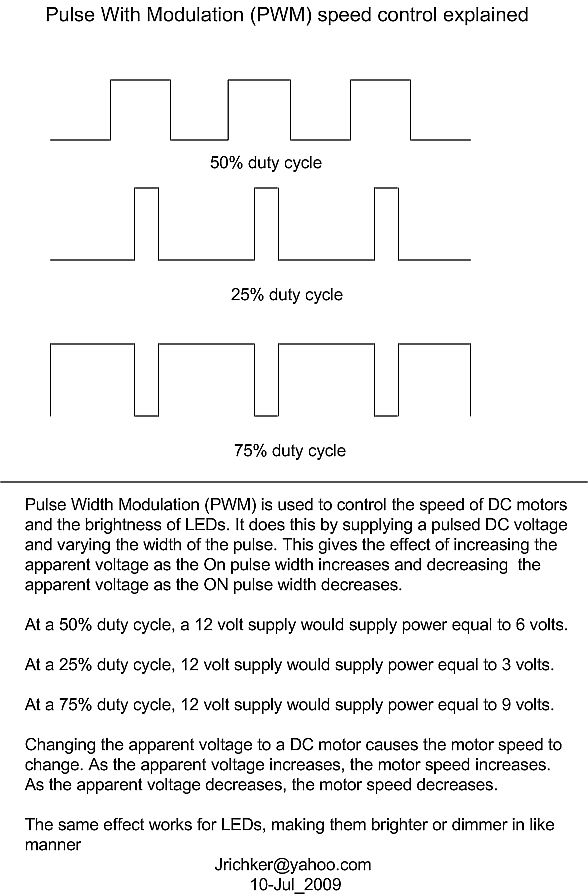

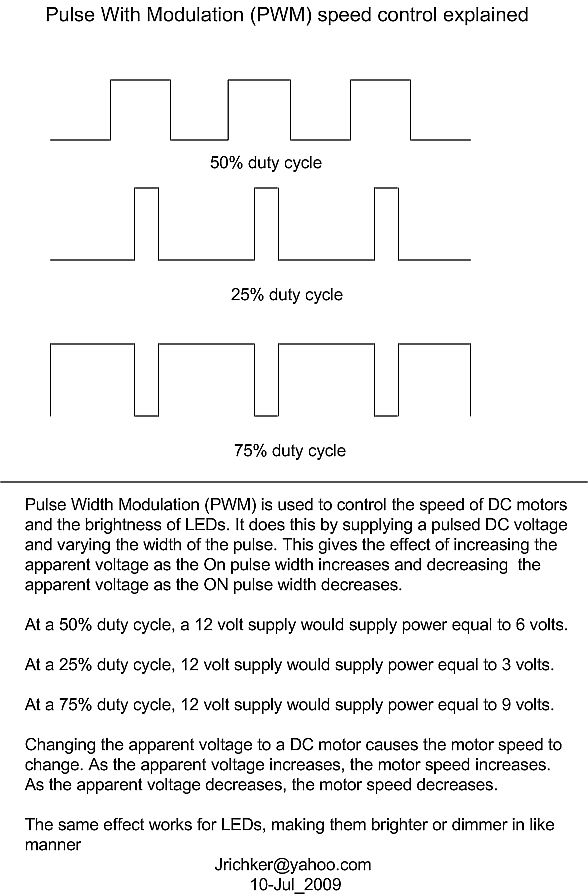

IAC doesn't work: look for +12 volts at the IAC red wire. Then check for continuity between the white/lt blue wire and pin 21 on the computer. The IAC connector contacts will sometimes corrode and make the IAC not work. The red wire on the IAC is always hot with the engine in run mode. The computer provides a ground for the current for the IAC. It switches the ground on and off, making a square wave with a varying duty cycle. A normal square wave would be on for 50% of the time and off for 50% of the time. When the idle speed is low, the duty cycle increases more than 50% to open the IAC more. When the engine speed is high, it decreases the duty cycle to less than 50% to close the IAC. An old-fashioned dwell meter can be used to check the change: I haven’t tried it personally, but it should work. In theory, it should read ½ scale of whatever range you set it on with a 50% duty cycle. An Oscilloscope is even better if you can find someone who has one and will help.

Automobile computers use current sink technology. They do not source power to any relay, solenoid or actuator like the IAC, fuel pump relay, or fuel injectors. Instead the computer provides a ground path for the positive battery voltage to get back to the battery negative terminal. That flow of power from positive to negative is what provides the energy to make the IAC, fuel pump relay, or fuel injectors work. No ground provided by the computer, then the actuators and relays don't operate.

We are going to supply an artificial ground path to the IAC instead of letting the computer supply the ground.

Start the engine and let it warm up.

Take one of the cheap inline fuse holders with a 5 amp fuse in it. Use it to bypass the blue/white wire to ground. You'll have to get creative probing the back side of the IAC wiring with safety pins or paper clips. Since the computer doesn't supply any voltage , but supplies a ground, that can't hurt the computer. The 5 amp fuse protects you and the wiring if there is an internal short in the IAC coil.

The engine should speed up when the fuse holder wire is grounded and slow down or stall when the fuse holder wire is disconnected from ground.

Recommended procedure for cleaning the IAC/IAB:

Conventional cleaning methods like throttle body cleaner aren’t very effective. The best method is a soak type cleaner used for carburetors. If you are into fixing motorcycles, jet skis, snowmobiles or anything else with a small carburetor, you probably have used the one gallon soak cleaners like Gunk or Berryman. One of the two should be available at your local auto parts store for $22-$29. Take the solenoid off the body and set it aside: the carb cleaner will damage some types of plastic parts. Soak the metal body in the carb cleaner overnight. There is a basket to set the parts in while they are soaking. When you finish soaking overnight, twist the stem of the IAB/IAC that sticks out while the blocker valve is seated. This removes any leftover deposits from the blocker valve seat. Rinse the part off with water and blow it dry with compressed air. The IAC/IAB should seal up nicely now. Once it has dried, try blowing through the bottom hole and it should block the air flow. If it doesn't block the airflow, there is still something that is gumming up the works. Reassemble and reinstall to check it out. Reassemble and reinstall to check it out.

Gunk Dip type carb & parts soaker:

Setting the base idle speed:

First of all, the idle needs to be adjusted to where the speed is at or below 600 RPM with the IAC disconnected. If you have a wild cam, you may have to raise this figure 100-150 RPM or so. Then the electrical signal through the IAC can vary the airflow through it under computer control. Remember that the IAC can only add air to increase the base idle speed set by the mechanical adjustment. The 600 RPM base idle speed is what you have after the mechanical adjustment. The IAC increases that speed by supplying more air under computer control to raise the RPM’s to 650-725 RPM’s. This figure will increase if you have a wild cam, and may end up between 800-950 RPM

Remember that changing the mechanical idle speed adjustment changes the TPS setting too.

This isn't the method Ford uses, but it does work. Do not attempt to set the idle speed until you have fixed all the codes and are sure that there are no vacuum leaks.

Disconnect the battery negative terminal and turn the headlights on. Leave the battery negative terminal disconnected for 5 minutes or so. Then turn the headlights off and reconnect the battery. This erases the computer settings that may affect idle performance.

Warm the engine up to operating temperature, place the transmission in neutral, and set the parking brake. Turn off lights, A/C, all unnecessary electrical loads. Disconnect the IAC electrical connector. Remove the SPOUT plug. This will lock the ignition timing so that the computer won't change the spark advance, which changes the idle speed. Note the engine RPM: use the mechanical adjustment screw under the throttle body to raise or lower the RPM until you get the 600 RPM mark +/- 25 RPM. A wild cam may make it necessary to increase the 600 RPM figure to 700 RPM or possibly a little more to get a stable idle speed.

Changing the mechanical adjustment changes the TPS, so you will need to set it.

When you are satisfied with the results, turn off the engine, and re-install the SPOUT and reconnect the IAC. The engine should idle with the range of 650-750 RPM without the A/C on or extra electrical loads. A wild cam may make this figure somewhat higher.

Automobile computers use current sink technology. They do not source power to any relay, solenoid or actuator like the IAC, fuel pump relay, or fuel injectors. Instead the computer provides a ground path for the positive battery voltage to get back to the battery negative terminal. That flow of power from positive to negative is what provides the energy to make the IAC, fuel pump relay, or fuel injectors work. No ground provided by the computer, then the actuators and relays don't operate.

We are going to supply an artificial ground path to the IAC instead of letting the computer supply the ground.

Start the engine and let it warm up.

Take one of the cheap inline fuse holders with a 5 amp fuse in it. Use it to bypass the blue/white wire to ground. You'll have to get creative probing the back side of the IAC wiring with safety pins or paper clips. Since the computer doesn't supply any voltage , but supplies a ground, that can't hurt the computer. The 5 amp fuse protects you and the wiring if there is an internal short in the IAC coil.

The engine should speed up when the fuse holder wire is grounded and slow down or stall when the fuse holder wire is disconnected from ground.

Recommended procedure for cleaning the IAC/IAB:

Conventional cleaning methods like throttle body cleaner aren’t very effective. The best method is a soak type cleaner used for carburetors. If you are into fixing motorcycles, jet skis, snowmobiles or anything else with a small carburetor, you probably have used the one gallon soak cleaners like Gunk or Berryman. One of the two should be available at your local auto parts store for $22-$29. Take the solenoid off the body and set it aside: the carb cleaner will damage some types of plastic parts. Soak the metal body in the carb cleaner overnight. There is a basket to set the parts in while they are soaking. When you finish soaking overnight, twist the stem of the IAB/IAC that sticks out while the blocker valve is seated. This removes any leftover deposits from the blocker valve seat. Rinse the part off with water and blow it dry with compressed air. The IAC/IAB should seal up nicely now. Once it has dried, try blowing through the bottom hole and it should block the air flow. If it doesn't block the airflow, there is still something that is gumming up the works. Reassemble and reinstall to check it out. Reassemble and reinstall to check it out.

Gunk Dip type carb & parts soaker:

Setting the base idle speed:

First of all, the idle needs to be adjusted to where the speed is at or below 600 RPM with the IAC disconnected. If you have a wild cam, you may have to raise this figure 100-150 RPM or so. Then the electrical signal through the IAC can vary the airflow through it under computer control. Remember that the IAC can only add air to increase the base idle speed set by the mechanical adjustment. The 600 RPM base idle speed is what you have after the mechanical adjustment. The IAC increases that speed by supplying more air under computer control to raise the RPM’s to 650-725 RPM’s. This figure will increase if you have a wild cam, and may end up between 800-950 RPM

Remember that changing the mechanical idle speed adjustment changes the TPS setting too.

This isn't the method Ford uses, but it does work. Do not attempt to set the idle speed until you have fixed all the codes and are sure that there are no vacuum leaks.

Disconnect the battery negative terminal and turn the headlights on. Leave the battery negative terminal disconnected for 5 minutes or so. Then turn the headlights off and reconnect the battery. This erases the computer settings that may affect idle performance.

Warm the engine up to operating temperature, place the transmission in neutral, and set the parking brake. Turn off lights, A/C, all unnecessary electrical loads. Disconnect the IAC electrical connector. Remove the SPOUT plug. This will lock the ignition timing so that the computer won't change the spark advance, which changes the idle speed. Note the engine RPM: use the mechanical adjustment screw under the throttle body to raise or lower the RPM until you get the 600 RPM mark +/- 25 RPM. A wild cam may make it necessary to increase the 600 RPM figure to 700 RPM or possibly a little more to get a stable idle speed.

Changing the mechanical adjustment changes the TPS, so you will need to set it.

When you are satisfied with the results, turn off the engine, and re-install the SPOUT and reconnect the IAC. The engine should idle with the range of 650-750 RPM without the A/C on or extra electrical loads. A wild cam may make this figure somewhat higher.

reviving this thread. Still not getting this to work. i had the car off the road for 8 months due to lack of funds and too many other projects. Now I have it back off the jacks. I just replaced the clutch and now that it is on the road i am reminded of all else that is wrong wiht the car.

IAC is still giving me issues. Reset the base idle and nothing has changed.The motor races when I start it and it will die at the first light I come too. It also revs up to 2500 between shifts. If I let the car stall and leave it of for 10 seconds and restart - it idles just fine. Still revs high though between shifts.

IAC is still giving me issues. Reset the base idle and nothing has changed.The motor races when I start it and it will die at the first light I come too. It also revs up to 2500 between shifts. If I let the car stall and leave it of for 10 seconds and restart - it idles just fine. Still revs high though between shifts.

reviving this thread. Still not getting this to work. i had the car off the road for 8 months due to lack of funds and too many other projects. Now I have it back off the jacks. I just replaced the clutch and now that it is on the road i am reminded of all else that is wrong wiht the car.

IAC is still giving me issues. Reset the base idle and nothing has changed.The motor races when I start it and it will die at the first light I come too. It also revs up to 2500 between shifts. If I let the car stall and leave it of for 10 seconds and restart - it idles just fine. Still revs high though between shifts.

Codes?

jozsefsz

15 Year Member

If you stop and restart the car, it exits "closed loop" and runs in "open loop" which is a little richer.

In closed loop, as the o2 sensors reports voltage and switches , the car will add / remove fuel and go from rich-lean-rich-lean etc. Which can cause loping.

You've got two different things going on. The racing at startup and between shifts indicates you may even have the base idle and idle air-bleed over-adjusted. The stalling tells me the opposite.

If I were a betting man, you may have a major vacuum leak somewhere. The IAC can't really compensate for that. Usual suspects are the evap purge stuff and that one line that goes under the intake. Also if you're running open breathers and haven't capped your PCV then this might happen. You may also have an issue with your o2 sensors or other fuel-delivery items but vacuum leaks are free to troubleshoot so I usually start there.

In closed loop, as the o2 sensors reports voltage and switches , the car will add / remove fuel and go from rich-lean-rich-lean etc. Which can cause loping.

You've got two different things going on. The racing at startup and between shifts indicates you may even have the base idle and idle air-bleed over-adjusted. The stalling tells me the opposite.

If I were a betting man, you may have a major vacuum leak somewhere. The IAC can't really compensate for that. Usual suspects are the evap purge stuff and that one line that goes under the intake. Also if you're running open breathers and haven't capped your PCV then this might happen. You may also have an issue with your o2 sensors or other fuel-delivery items but vacuum leaks are free to troubleshoot so I usually start there.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 11

- Views

- 677

- Replies

- 6

- Views

- 1K

- Replies

- 3

- Views

- 813

- Replies

- 10

- Views

- 2K