alright...this is the first brake system I have had to make....not talking about calipers...but lines and master cylinders...etc...

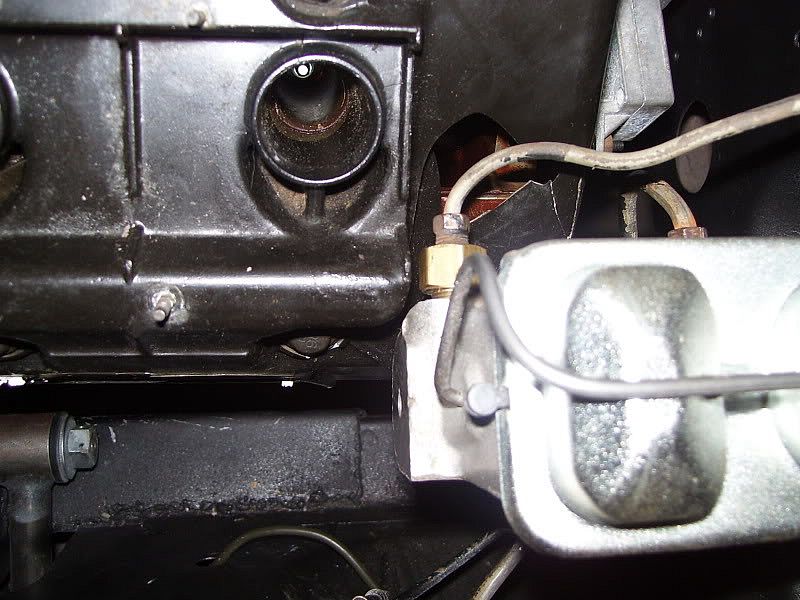

I have a dual bowl 85 T-bird master cylinder with 7/8" bore for a planned 4 wheel manual disc brake system...front calipers are GM single piston deals that came with the mustang II kit(for now anyway) rear calipers are 84 lincoln mark vii...I am trying to hook up my brake system...so far I have only the MC and the stock '66 distribution block...I have bent and flared a line from each of the front calipers to the distribution block...distribution block has 3 ports that are 3/16" and one that I am assuming is 1/4"(smaller than 5/16" anyway) so right now 2 of 3 ports are used...one of the ports will go to the big bowl on the MC and the last 3/16" port...I'm assuming I plug it correct?(obviously its not going to be left open, just making sure I am seperating front and rear brakes into 2 seperate systems) now for the rear brakes I havent bent any line because I'm unsure...I assume I run a line from the small bowl on the MC and plug it into an adjustable proportioning valve and then run it to the rear axle and to a y-block, from the y-block to the flexible lines? thats my understanding of it...am I right in all my assumptions here? its pretty simple, but like I said, this is the first time I have done this

I have a dual bowl 85 T-bird master cylinder with 7/8" bore for a planned 4 wheel manual disc brake system...front calipers are GM single piston deals that came with the mustang II kit(for now anyway) rear calipers are 84 lincoln mark vii...I am trying to hook up my brake system...so far I have only the MC and the stock '66 distribution block...I have bent and flared a line from each of the front calipers to the distribution block...distribution block has 3 ports that are 3/16" and one that I am assuming is 1/4"(smaller than 5/16" anyway) so right now 2 of 3 ports are used...one of the ports will go to the big bowl on the MC and the last 3/16" port...I'm assuming I plug it correct?(obviously its not going to be left open, just making sure I am seperating front and rear brakes into 2 seperate systems) now for the rear brakes I havent bent any line because I'm unsure...I assume I run a line from the small bowl on the MC and plug it into an adjustable proportioning valve and then run it to the rear axle and to a y-block, from the y-block to the flexible lines? thats my understanding of it...am I right in all my assumptions here? its pretty simple, but like I said, this is the first time I have done this

Could be wrong though but thought I would just put it out there.

Could be wrong though but thought I would just put it out there.