You posted only one set of codes; didn't you get the engine running codes too?

Code 54 – ACT sensor out of range. Broken or damaged wiring, bad ACT sensor. Note that that if the outside air temp is below 50 degrees F that the test for the ACT can be in error.

Check the resistance of the black/white wire to battery ground. If it is less than 2 ohms, it is good. If it is more than 2 ohms, the black/white wire has bad connections or a broken wire. Always take resistance measurements with the circuit powered off.

See the graphic for the 10 pin connector circuit layout.

Then check the resistance of the ACT sender located in the #5 intake runner on most 5.0 stangs.

ACT & ECT test data:

The ACT & ECT have the same thermistor, so the table values are the same

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts. It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in the lower intake manifold, the voltage readings will be lower because of the heat transfer. Here's the table :

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

Code 33 - Insufficient EGR flow detected.

Look for vacuum leaks, cracked vacuum lines, failed EGR vacuum regulator. Check to see if you have 10” of vacuum at the EGR vacuum connection coming from the intake manifold. Look for electrical signal at the vacuum regulator solenoid valves located on the rear of the passenger side wheel well. Using a test light across the electrical connector, it should flicker as the electrical signal changes. Remember that the computer does not source any power, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

Check for resistance between the brown/lt green wire on the EGR sensor and pin 27 on the computer: you should have less than 1.5 ohm.

Backside view of the computer wiring connector:

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host)

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

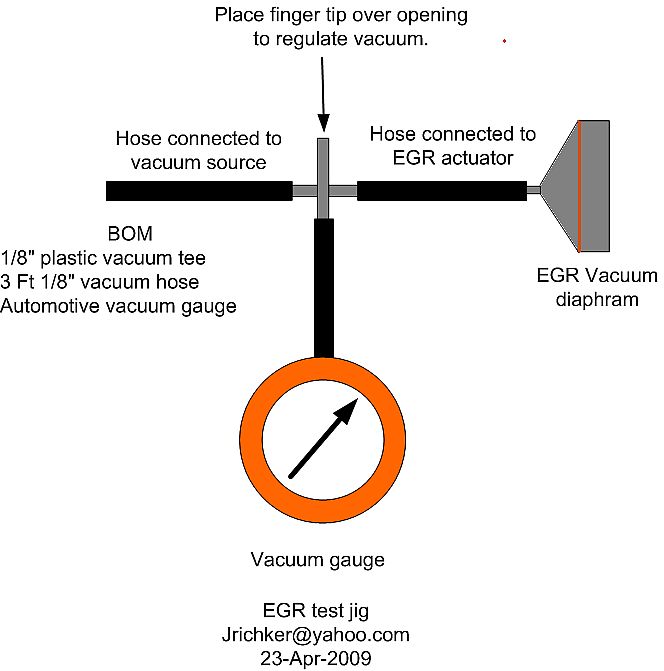

EGR test procedure courtesy of cjones

to check the EGR valve:

bring the engine to normal temp.

connect a vacuum pump to the EGR Valve or

see the EGR test jig drawing below. Connect the test jig or to directly to manifold vacuum.

Do not connect the EGR test jig to the EVR (Electronic Vacuum Regulator).

apply 5in vacuum to the valve.

Using the test jig, use your finger to vary the vacuum

if engine stumbled or died then EGR Valve and passage(there is a passageway through the heads and intake) are good.

if engine did NOT stumble or die then either the EGR Valve is bad and/or the passage is blocked.

if engine stumbled,

connect EGR test jig to the hose coming off of the EGR Valve.

Use your finger to cap the open port on the vacuum tee.

snap throttle to 2500 RPM (remember snap the throttle don't hold it there).

did the vacuum gauge show about 2-5 in vacuum?

if not the EVR has failed

EGR test jig

The operation of the EGR vacuum regulator can be checked by using a test light applied across the wiring connector. Jumper the computer into self test mode and turn the key on but do not start the engine. You will hear all the actuators (including the EVR vacuum regulator) cycle. Watch for the light to flicker: that means the computer has signaled the EGR vacuum regulator successfully.

Code 10 is a spacer code and has no value attached to it.

Since you have said that you have a low level of proficiency in electrical matters, here's some help before you get started.

Automotive circuits are mostly simple stuff: a power source, a connection path, a control device, a load, and a ground.

The battery/alternator is the positive power source.

The wire and fuses are the connection path.

Control devices are switches, relays and sensors.

A load is a light, motor, solenoid, relay coil or heater element.

In automotive circuits, grounds are the return path so the electrical power can flow from the load to the negative side of the power source.

Electricity flows like water:

Voltage is like pressure,

Current in amps is like volume,

Resistance is like the kink you put in a garden hose to decrease the pressure or volume.

Power is pressure multiplied by volume or voltage multiplied by current (amps)

Digest that, and you just got the first 3 days of Electricity 101.

Use some jumper wires (connection path and ground) to hook up a switch (control device), a battery (power source), a light bulb (load). Now make the light turn on and off with the switch.

That's the electrical lab for the first week of Electricity 101.

For free automotive electrical training, see

Automotive Training and Resource Site . Once you are there, select online instruction. I have personally reviewed the material and it is very good. If you are new to automotive electrical troubleshooting, I highly recommend you spend a hour or so going through the material. You'll save at least that much time troubleshooting problems.

Using a Multimeter or DVM

Almost every meter has a different method for showing an open circuit. An open circuit is one with a break in it somewhere. That break can be a switch turned off, a fuse blown, a lamp burned out, a bad connector, a damaged circuit board or a cut or burned wire.

Without reading the instruction manual that came with your meter, I would not try to guess what your readings mean.

Step 1.) Find the instruction book that came with your Multimeter or DVM. Read it and familiarize yourself with how it works and how use it. If you lost the book or didn’t get one with it, do a Google search on the web to find the manufacturer’s web site & download a copy of the manual. Remember that while some meters auto-range to find the correct voltage range, the Ohms function ranges are usually set by the selector switch. Most of the resistance testing done in automotive troubleshooting uses the lowest Ohms range possible.

Step 2. ) Make sure that you know what test lead plugs into which jacks on the Multimeter or DVM. There are usually several different jacks on most Multimeter or DVMs, and they have different functions. Make sure that your battery(s) in the Multimeter are good: if you have any doubts, replace the battery(s).

Step 3.) Once you are sure that the Multimeter or DVM is functional and you have the leads plugged into the jacks for Ohms ( the Ω symbol), do some simple measurements to make sure that you know how to use it correctly. Set the switch to the lowest range and touch the leads together: you should not see “nothing” but you should see 0.3-1.0 ohms. Measure a 60 watt light bulb: cold it will measure about 17.5 Ohms. It you measure it while it is hot, the reading will be greater.

Step 4.) Make several test measurements using the ohms function and the DC volts function.

Remember all resistance measurements must be done with the power off the circuit. This avoids false readings and possible damage to the ohmmeter.. Repeat steps 3 & 4 until you are sure that you can do it without making any mistakes.

Step 5.) Then see

| Repair Guides | Understanding And Troubleshooting Electrical Systems | Basic Electrical Theory | AutoZone.com and carefully study ALL the information under the Heading Chassis Electrical, Basic Electricity – Understanding & Troubleshooting

Step 6.) Apply what you have learned and make the test measurements using the information in the wiring diagrams & my previous posts.

Don't be in too much of a hurry to bolt all the new, pretty, shiny parts together. Take the simple steps now and you will save yourself lots of time and trouble later.

millimeter, but don't know how to use it

millimeter, but don't know how to use it millimeter, but don't know how to use it

millimeter, but don't know how to use it