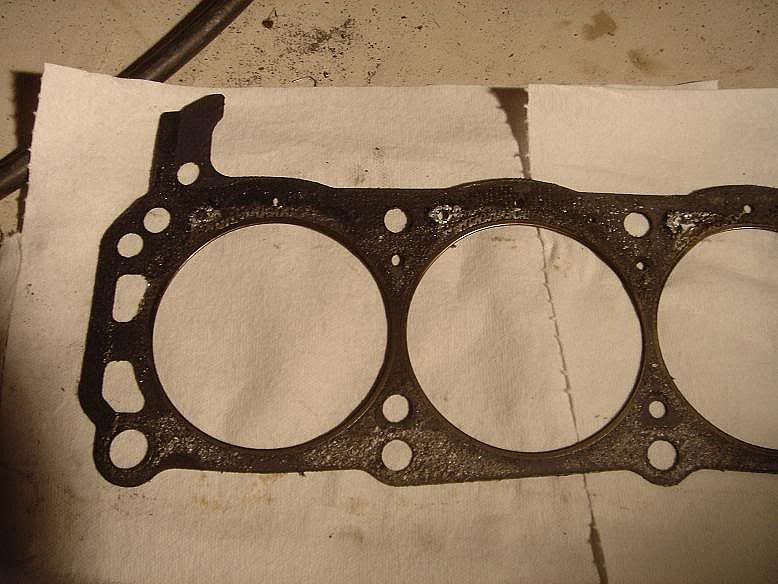

I found out that the drivers side blew, which is the easy side to dao (2 hr. job). Therefore, I may just put a new one in and call it a day. Otherwise, I'll want to buy forged pistons, main bearing, k-member, motor mounts etc.. and I have NO money for that for a long time.

I pretty sure that since my car shut off right after it happened and I didn't hear any loud or wierd noise, it SHOULD just be the gasket.

I pretty sure that since my car shut off right after it happened and I didn't hear any loud or wierd noise, it SHOULD just be the gasket.

surface for the nut to hold. Not sure, but I think thats it

surface for the nut to hold. Not sure, but I think thats it