How to remove stripped lugs / lugbolts / studs

Hey guys, I thought I would stick this on here.

Had a neighbors GT in and it had stripped lugs with the nuts still attached. So whenever you would try to turn the nut, the whole lug would spin. The Hub holes were stripped also.

Since there is limited room from behind the wheel, it's hard to get anything to cut off the head.

I started by knocking the center of the nut with a punch:

The stock nuts are fairly cheap and break easily.

After you've cleared out some room, I used a 1/2 roper bit. Not sure what the technical term is.

I used an electrical drill instead of air because it takes about 5/6 minutes for it to break through.

Once it does, simply (air or manual) punched a chisel and knocked the lug out.

Since you are there, the ones that aren't stripped, might as well change em as well. Takes an easy swipe to knock em through.

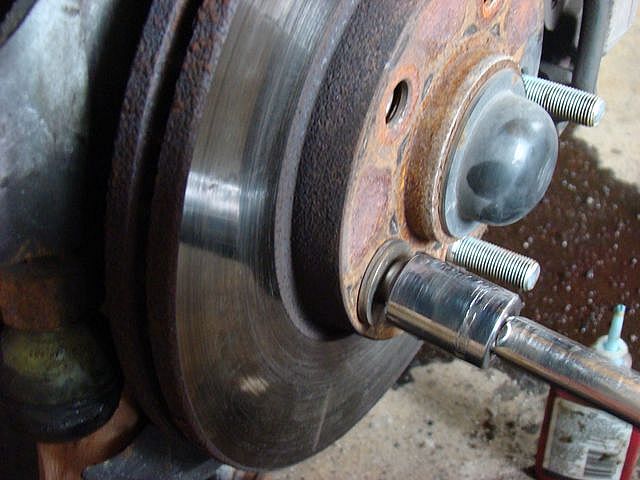

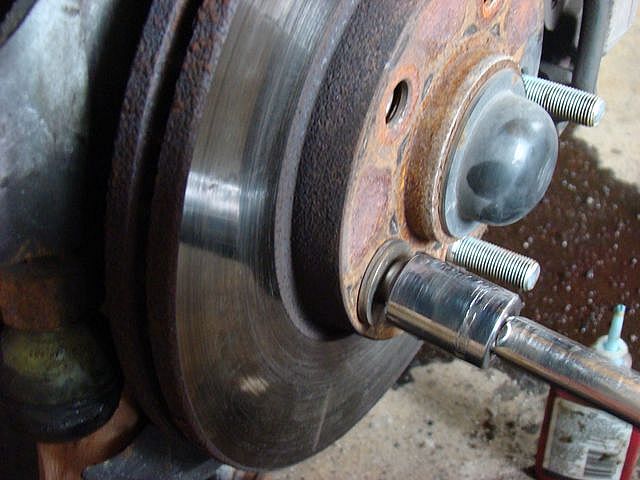

Once they are all out, replace lug from the back. You may have to turn the rotor to find the access point back there and can be done with the brake rotor backing plate on. Feed the lug in and line up the grooves. Use a couple washers and a clear nut (clear as in no head) and tighten it down until the lug is seated.

Repeat for all 5 and voila...new studs.

Here is a stripped hub hole and a good one:

I used loc-tite on the stripped hubs and they did seat. It wasn't in the budget to replace the hub. And this is also a good time to replace the brakes.

Hey guys, I thought I would stick this on here.

Had a neighbors GT in and it had stripped lugs with the nuts still attached. So whenever you would try to turn the nut, the whole lug would spin. The Hub holes were stripped also.

Since there is limited room from behind the wheel, it's hard to get anything to cut off the head.

I started by knocking the center of the nut with a punch:

The stock nuts are fairly cheap and break easily.

After you've cleared out some room, I used a 1/2 roper bit. Not sure what the technical term is.

I used an electrical drill instead of air because it takes about 5/6 minutes for it to break through.

Once it does, simply (air or manual) punched a chisel and knocked the lug out.

Since you are there, the ones that aren't stripped, might as well change em as well. Takes an easy swipe to knock em through.

Once they are all out, replace lug from the back. You may have to turn the rotor to find the access point back there and can be done with the brake rotor backing plate on. Feed the lug in and line up the grooves. Use a couple washers and a clear nut (clear as in no head) and tighten it down until the lug is seated.

Repeat for all 5 and voila...new studs.

Here is a stripped hub hole and a good one:

I used loc-tite on the stripped hubs and they did seat. It wasn't in the budget to replace the hub. And this is also a good time to replace the brakes.

had this happen to me a few years ago and did just that , at the time I had to use the cordless and used a few batteries to get it done !

had this happen to me a few years ago and did just that , at the time I had to use the cordless and used a few batteries to get it done !