What are you running that needs 30 LB injectors? Those injectors would be OK on a 351W or a 302 with pressurized induction, but too big for a normally aspirated 302.

Fuel injector sizing & injector photos

Revised 11-Dec-2011 to add larger injector sizes to injector table

Injector HP ratings: divide flow rating by.5 and multiply the result by the number of injectors. This uses a 100% duty cycle.

These ratings are for naturally aspirated engines at the flywheel.

Example:

19/.5 = 38, 38 x 8 = 304 HP

24/.5 = 48, 48 x 8 = 384 HP

30/.5 = 60, 60 x 8 = 480 HP

36/.5 = 72, 72 x 8 = 576 HP

42/.5 = 84, 84 x 8 = 672 HP

The preferred duty cycle is about 85% maximum, so for a safety factor multiply the final figure times .85.

19/.5 = 38, 38 x 8 = 304 HP x .85 = 258 HP

24/.5 = 48, 48 x 8 = 384 HP x .85 = 326 HP

30/.5 = 60, 60 x 8 = 480 HP x .85 = 408 HP

36/.5 = 72, 72 x 8 = 576 HP x .85 = 490 HP

42/.5 = 84, 84 x 8 = 672 HP x .85 = 571 HP

Remember that the above ratings are at 39 PSI. Increasing the pressure will effectively increase the flow rating. Example: a 19 lb injector will flow 24 lbs at 63 PSI, and a 24 lb injector will flow 30 lbs at 63 PSI.

See

http://users.erols.com/srweiss/ to get the calculators used in these examples.

Here's the duty cycle explanation. Duty cycle is how much of the time the intake is open the injectors are turned on. The 85% figure means that for 85% of the time the intake valve is open, the injectors are spraying. The idea is that you want some percentage of the duty cycle left over so that you have some room to grow the process.

If you are at 100% and you need more fuel, all you can do is turn up the fuel pressure. That means the whole fuel curve from idle to WOT is affected. Maybe you are already too rich at idle, and turning up the fuel pressure makes it worse. If you had some injector duty cycle left to play with, a custom tune could use that where it is needed. That would not over richen the whole range from idle to WOT.

If you did turn up the fuel pressure, you might be able to change the injector duty cycle to get the air/fuel mixture ratio you want since the injectors will have extra fuel delivery capability.

With larger than stock injectors or higher that stock fuel pressure, you will need an aftermarket MAF that matches the injector size. The MAF “lies” to the computer to get a fuel delivery schedule that meets the engine’s needs and isn’t too rich or too lean. The best strategy is an aftermarket MAF and a custom tune to insure the best air/fuel ratio over all the RPM range.

Don't forget to increase the fuel pump size when you increase injector size or significantly increase the fuel pressure

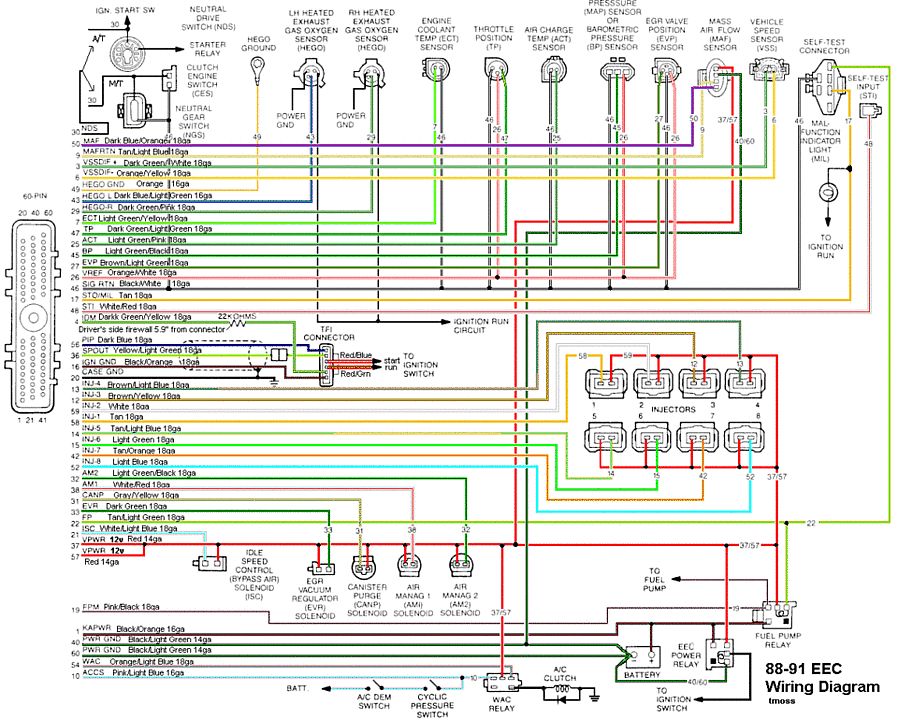

Diagram courtesy of Tmoss & Stang&2birds

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pinout

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif