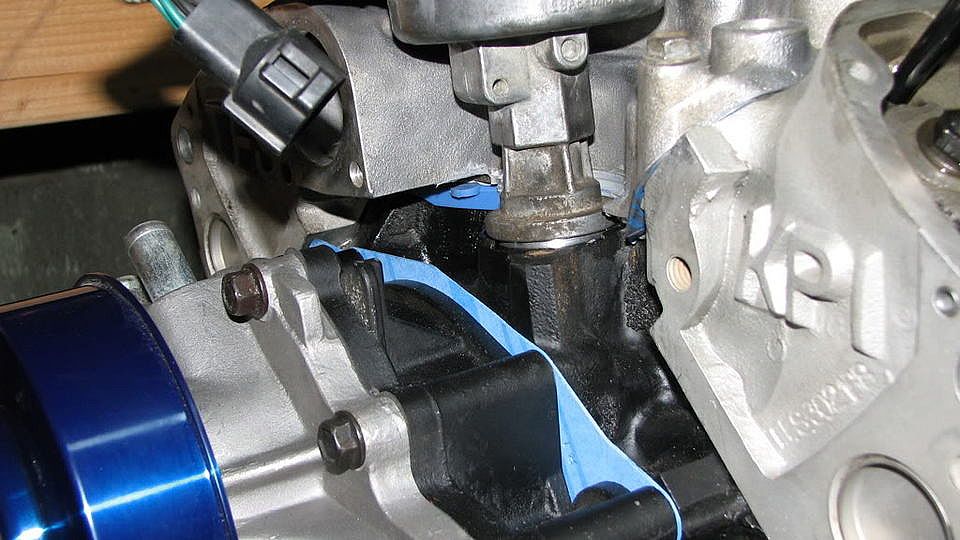

adam95gt's motor

he can correct me, but I think:

306 cobra motor

stock pistons/rods

.010" over mains

tfs hi ports pedestal mounts

1.6RR

6.7" pushrods

double roller timing chain

stock distributor msd cap stock rotor

melling HV oil pump and oil pump drive

the video can be seen here

http://youtube.com/watch?v=crZnw_WHe3Y

none of the rocker arms were tightened for this so it is certainly not a piston to valve issue as none of the valves should be opening at this point.

the shortblock was assembled so we do not believe it is a bottom end problem, it rotated fine and with no noise. there are machine shop indications of a ring job and a reground crank .010 over.

with the heads and everything you see in the video on EXCEPT the distributor, it did not make this noise.

is this abnormal, or since there is only 1.5 qts oil in the motor right now is this the oil pump sucking air and oil? if I have time today (packing for apartment), I am going to pull the oil pump and the distributor and see if I can isolate which one it is. distributor had a very tough time going in, but this could also be caused by a problem with oil pump/drive. when we were putting distributor in, we looked down the hole and the oil pump drive was centered and looked okay.

could it be an issue with the disty drive on the cam or us not having clocked the disty correct? I've put on in incorrectly before and it never made a noise like this, just obvious run bad or not at all.

he can correct me, but I think:

306 cobra motor

stock pistons/rods

.010" over mains

tfs hi ports pedestal mounts

1.6RR

6.7" pushrods

double roller timing chain

stock distributor msd cap stock rotor

melling HV oil pump and oil pump drive

the video can be seen here

http://youtube.com/watch?v=crZnw_WHe3Y

none of the rocker arms were tightened for this so it is certainly not a piston to valve issue as none of the valves should be opening at this point.

the shortblock was assembled so we do not believe it is a bottom end problem, it rotated fine and with no noise. there are machine shop indications of a ring job and a reground crank .010 over.

with the heads and everything you see in the video on EXCEPT the distributor, it did not make this noise.

is this abnormal, or since there is only 1.5 qts oil in the motor right now is this the oil pump sucking air and oil? if I have time today (packing for apartment), I am going to pull the oil pump and the distributor and see if I can isolate which one it is. distributor had a very tough time going in, but this could also be caused by a problem with oil pump/drive. when we were putting distributor in, we looked down the hole and the oil pump drive was centered and looked okay.

could it be an issue with the disty drive on the cam or us not having clocked the disty correct? I've put on in incorrectly before and it never made a noise like this, just obvious run bad or not at all.

This engine build is pissing me off!

This engine build is pissing me off!