So calling the intake done. Just need to reinstall my vac port fittings, then box it up and store it. Need somr hardware but I have the dimensions I need so I'll order soon. But after paint and seeing it in sunlight...it's perfect. Looks oem original

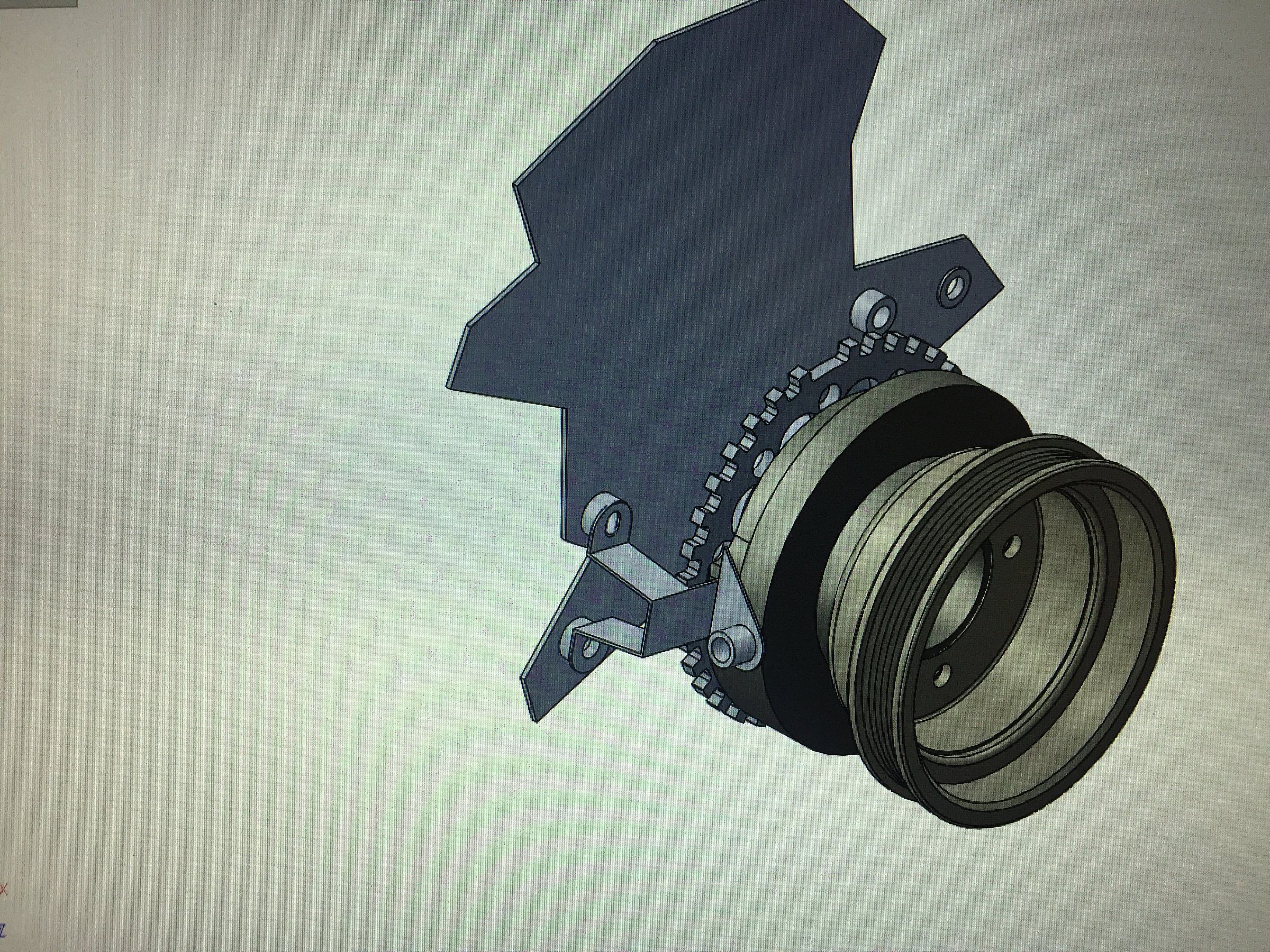

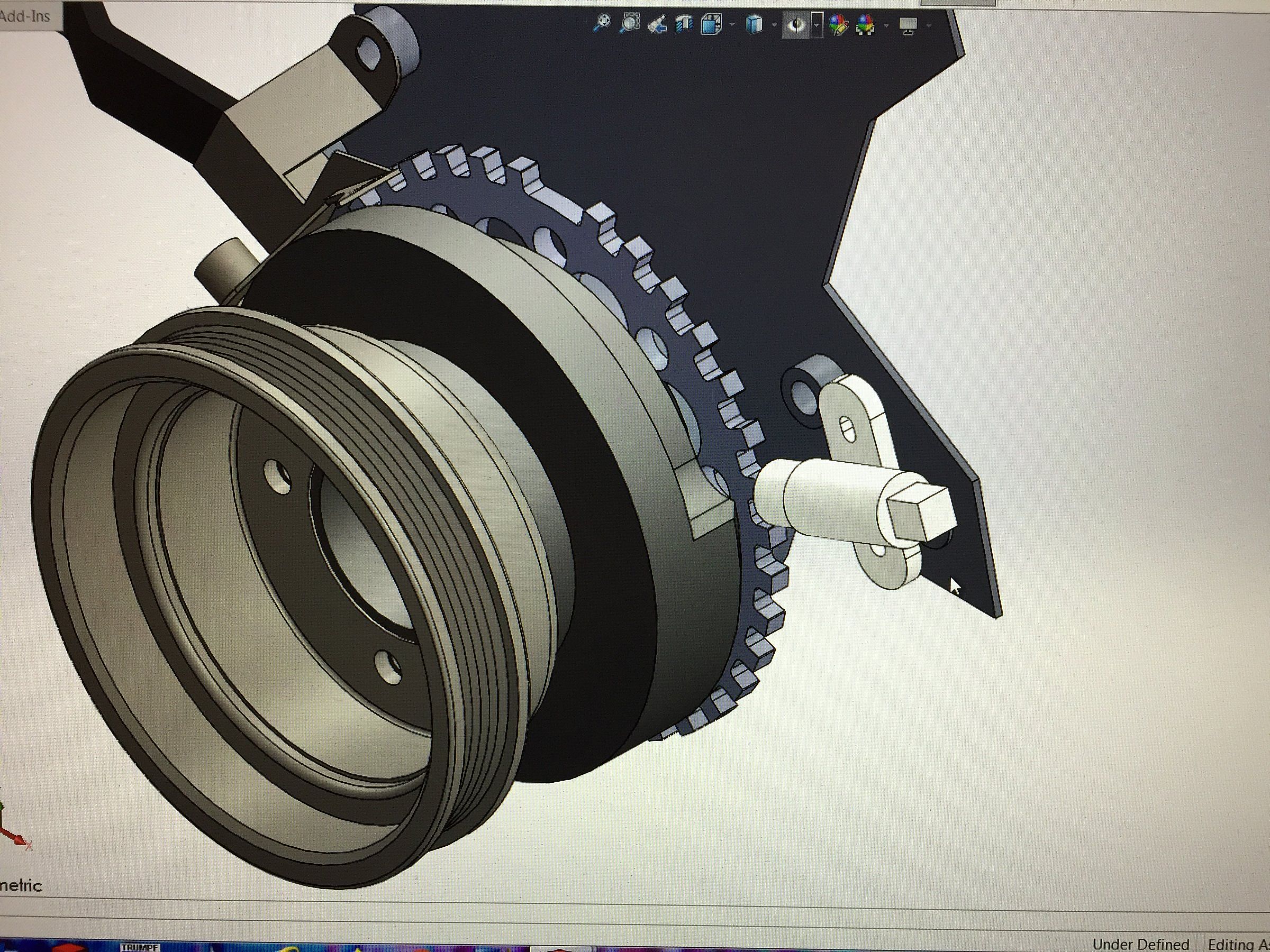

As for trigger wheel. Got an idea. I was thinking of mounting it behind the balancer. But instead of drilling into the rubber mounted balancer, I'll mount it to this unmachined hub area.

Now I was thinking of laser cutting to size and pressing it home. Downside is I get one shot to get it aligned sand sized correctly.

It should tuck up nicely and still give clearance.

Other option is to use and existing trigger wheel and machine up a spacer.

Explorer balancers are expensive for some reason on eBay, but Taurus 3.0 balancers can be had under $20. Look very similar and it's 6.5" in OD which is a usable dimension for the balancer.

Why use a factory wheel? It's probably balanced properly (notice the missing hole to add material where the missing tooth is) and more readily available. I'm pretty sure I can calculate dynamic balance on my cad software so I'll examine that aspect on my wheel design as well

Problem is cutting the necessary adapter ring, pressing it together, and then pressing it on the hub and getting it all sized properly so it doesn't slip at WOT.

It would be slick, but a more complex install.

Or method #3...drill tap some 6-32s into the inner portion of the balancer ring (inside the rubber) and bolt the ring to the backside with screws. Would allow for some adjustment, but you'd need to pull the balancer

I found a cheap timing cover on eBay. Going to model it up in CAD and use that to build a design for a crank sensor mount. I picked up a Taurus 3.0 crank sensor as well. trying to mimic something like this.