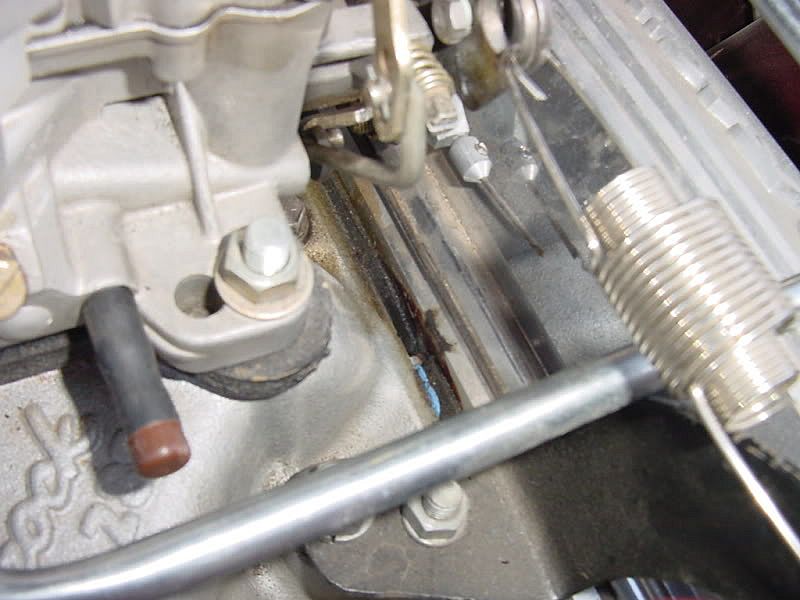

New Ford Racing crate engine with aluminum GT-40 cylinder heads Pt# M-6049-X303

For now, I bolted on my old Edelbrock Performer Intake with a 600 cfm carb. (I plan on going EFI sometime in the future)

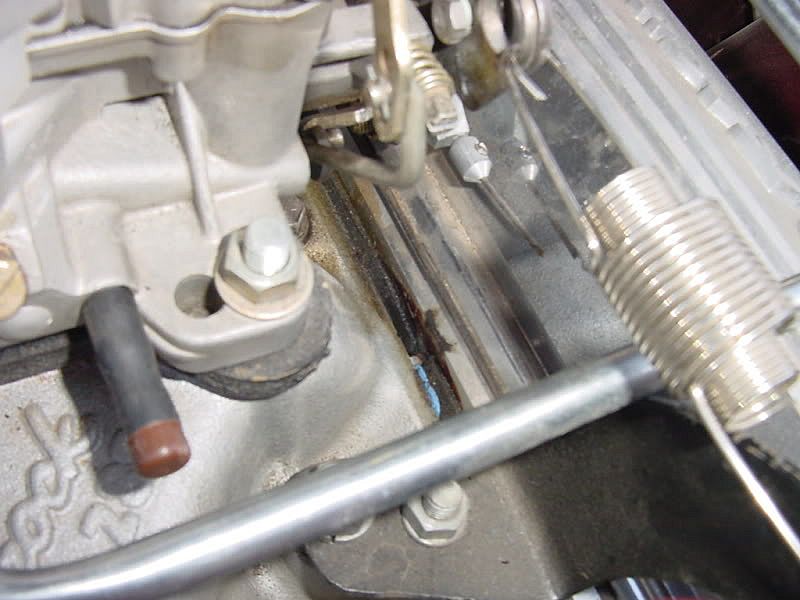

I have the idle screw cranked way up and it still sputters and dies. When I spray carb fluid around the intake manifold gasket at the heads, the idle goes up indicating a leak. I tried to re-torque the intake gaskets, but no difference. When I put them on, I noticed they didn't line up as good as I would have liked.

The oil looks a tad milky too, indicating the coolant/water is making its way into the crankcase.

I'm not sure what gaskets they were, I threw away the box and can't find the receipt. I know they were Fel-Pro.

What gaskets should I be using? The carb intake type or the EFI intake type?

For now, I bolted on my old Edelbrock Performer Intake with a 600 cfm carb. (I plan on going EFI sometime in the future)

I have the idle screw cranked way up and it still sputters and dies. When I spray carb fluid around the intake manifold gasket at the heads, the idle goes up indicating a leak. I tried to re-torque the intake gaskets, but no difference. When I put them on, I noticed they didn't line up as good as I would have liked.

The oil looks a tad milky too, indicating the coolant/water is making its way into the crankcase.

I'm not sure what gaskets they were, I threw away the box and can't find the receipt. I know they were Fel-Pro.

What gaskets should I be using? The carb intake type or the EFI intake type?

Did or did not use the end gaskets ? Thicker gaskets will help raise the intake, I've seen SBF gaskets that are up to .090 thick, and possibly some thicker than that. Felpro makes Ford's gaskets, may as well buy Felpros, if they're cheaper. No two intakes are going to fit any one engine the same. I had my Canfields milled .060 for a previous build and had to mill the Vic Jr I used on that build to get it to fit. Now I've got the same set of heads on my 331 and the 3x2 intake fit with only a little opening up of the bolt holes. No milling was neccessary. I've seen the same thing happen on a 400 Ford. I milled that motor's heads .030, the block's deck .020 and never had to mill the intake (Performer 400)

Did or did not use the end gaskets ? Thicker gaskets will help raise the intake, I've seen SBF gaskets that are up to .090 thick, and possibly some thicker than that. Felpro makes Ford's gaskets, may as well buy Felpros, if they're cheaper. No two intakes are going to fit any one engine the same. I had my Canfields milled .060 for a previous build and had to mill the Vic Jr I used on that build to get it to fit. Now I've got the same set of heads on my 331 and the 3x2 intake fit with only a little opening up of the bolt holes. No milling was neccessary. I've seen the same thing happen on a 400 Ford. I milled that motor's heads .030, the block's deck .020 and never had to mill the intake (Performer 400) . I've had good luck with the Permatex Ultra Black RTV for the water ports and end seals.

. I've had good luck with the Permatex Ultra Black RTV for the water ports and end seals.