Ok thanks I did run the cylinder test a while back when I first got the engine back together and it did pass but can't hurt to check it again. I currently have the chip out and that has caused the ck engine light to come on due to all the emissions being removed, will I be able to run the test under these conditions or should I reinstall the chip?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Newbie Needs Help With Slight Idle Issue And Hesitation

- Thread starter DanstangLI

- Start date

-

Sponsors (?)

Ok thanks I did run the cylinder test a while back when I first got the engine back together and it did pass but can't hurt to check it again. I currently have the chip out and that has caused the ck engine light to come on due to all the emissions being removed, will I be able to run the test under these conditions or should I reinstall the chip?

One of the engine running tests will fail, but as long as the IAC/IAB can control the idle speed, the cylinder balance test will run.Ok thanks I did run the cylinder test a while back when I first got the engine back together and it did pass but can't hurt to check it again. I currently have the chip out and that has caused the ck engine light to come on due to all the emissions being removed, will I be able to run the test under these conditions or should I reinstall the chip?

Ok great will go through that later today, I just spoke with BAMA about the issue with the chip and they seem a little surprised at the issue with the chip causing an idle surge but are supposed to get back to me with some possible solutions so will see where that takes me. I will post my results on the cyl test, thanks again.One of the engine running tests will fail, but as long as the IAC/IAB can control the idle speed, the cylinder balance test will run.

OK here are the results my head is beginning to spin maybe I should have gotten a nice four eyed and stuck with what I know best Carburetors! This is with no chip so i'm sure many of these codes are emissions relatedOne of the engine running tests will fail, but as long as the IAC/IAB can control the idle speed, the cylinder balance test will run.

KOEO

31/81/82/85/84

KOER

94/44/31/12

for the cyl test I ran it twice first was only cyl #7

2nd test showed cyl #6 and #2

I just had all the plugs out yesterday and all looked good, the wire on cyl #4 boot is heat damaged but that cyl isn't coming up. The wires are brand new and when I had the heads off the engine there is no lip on the cylinder walls so i'm doubting this is compression related and the heads are brand new and I don't have a compression tester but will get one if necessary. Any thoughts as to my next step, should I re-install the chip and run the tests and see if there is any change on the cyl test? Thanks again I owe you all for your time and help!

Also forgot to mention I have my timing light still connected and while waiting for the engine to warm up I tried moving the electrode to different cylinders and noticed the pulse on the timing is significantly different on several of the cylinders to the point I cant count the flashes but on some it is a steady pulse and countable, this doesnt seem right but that is a novice statement so would appreciate any insight on this as well. Thank youOne of the engine running tests will fail, but as long as the IAC/IAB can control the idle speed, the cylinder balance test will run.

Any help would be really appreciated I want to get this beast back on the streets and have some fun before the winter is here, i'm thinking distributor but I dont want to just go get another distributor and not have that be the answer. I'm thinking that since at a light rpm of 2000 it feels like its missing and at wot it stumbles and the fact that the timing light is showing inconsistent pulses across several cylinders, maybe the pick up is not working properly. I did get the distributor used on Ebay and it is MSD which i'm reading a lot of negative about there electronics, maybe I should get a pick up assembly or pick up a rebuilt motorcraft unit? I guess I could get a used one on Ebay to. I have to order wires due to the #4 cyl boot damage and going to get the TPS as well anyone think i'm going the right direction here? Ok please let me know what you all think thanks.Also forgot to mention I have my timing light still connected and while waiting for the engine to warm up I tried moving the electrode to different cylinders and noticed the pulse on the timing is significantly different on several of the cylinders to the point I cant count the flashes but on some it is a steady pulse and countable, this doesnt seem right but that is a novice statement so would appreciate any insight on this as well. Thank you

Ok I'm impatient but thinking of taking my ride to a local shop and see if they can more precisely diagnose this and will post my results when they are avail thanks to everyone for your help on thisOne of the engine running tests will fail, but as long as the IAC/IAB can control the idle speed, the cylinder balance test will run.

Ok took a few days off from the Fox and have been back at it now and didnt take it to a shop! I got a stock distributor to borrow and swapped it out and no significant difference! So my idea of the pick up going is out the window, I also replaced the tps and no help but I did ck the voltage at the tps and same on both the tps's the voltage increases with the throttle plate movement but at about 3.3 volts or so it drops for a second which seems suspicious I just don't know what to do with that so any ideas on that would be great. I did a compression test and all cylinders are good I ran two tests and performed it on a cold engine the shorty headers just get to damn hot

I did a compression test and all cylinders are good I ran two tests and performed it on a cold engine the shorty headers just get to damn hot

the results were

#1 141

#2 143

#3 147

#4 135

#5 142.5

#6 150

#7 145

#8 145

The numbers are within the 10% allowance and seem great the engine has a little over 50k mi.

I took the car for a ride after the compression test and with the stock distributor and did notice there is some backfiring when I get on the car and then let off the throttle its more of a popping I would say, off the line the car is a little hesitant but fine through the rest of the rpm's. Im going to run the KOEO&KOER and cyl tests again will post the results also I did all of this with the chip back in I have tried the three different settings on the chip and have noticed the most aggressive setting it idles the best, I am also waiting to hear back from SCT on some ideas they are working on in the mean time any more input would be appreciated I feel like I may have to bring it to shop since I'm running out of ideas!

the results were

#1 141

#2 143

#3 147

#4 135

#5 142.5

#6 150

#7 145

#8 145

The numbers are within the 10% allowance and seem great the engine has a little over 50k mi.

I took the car for a ride after the compression test and with the stock distributor and did notice there is some backfiring when I get on the car and then let off the throttle its more of a popping I would say, off the line the car is a little hesitant but fine through the rest of the rpm's. Im going to run the KOEO&KOER and cyl tests again will post the results also I did all of this with the chip back in I have tried the three different settings on the chip and have noticed the most aggressive setting it idles the best, I am also waiting to hear back from SCT on some ideas they are working on in the mean time any more input would be appreciated I feel like I may have to bring it to shop since I'm running out of ideas!

Ok ran the KOEO/KOER and cyl test the results are

KOEO

#85

#15

KOER

#4

#11

Cyl test

#4

I believe the 85 is for the canister which is disconnected and 15 i probably since I had disconnected the battery for the distributor swap KOER results are fine, on the cyl test the last one I did came up with # 7/6/2 now im only getting #4 which has a burnt spark plug boot on it so maybe there is a slight arcing I checked with a screwdriver and couldn't get a spark to jump from the boot. I have a set of Taylor wires on the way that were recommended by Mikestang63 and will put those on as soon as they get here and see if that clears the cyl test. I'm stumped until then so will hope I get some input here guys anything is appreciated i'm gonna be really bummed if I cant get my baby on the road and enjoy some top down driving before the winter, thank you everyone for your help

KOEO

#85

#15

KOER

#4

#11

Cyl test

#4

I believe the 85 is for the canister which is disconnected and 15 i probably since I had disconnected the battery for the distributor swap KOER results are fine, on the cyl test the last one I did came up with # 7/6/2 now im only getting #4 which has a burnt spark plug boot on it so maybe there is a slight arcing I checked with a screwdriver and couldn't get a spark to jump from the boot. I have a set of Taylor wires on the way that were recommended by Mikestang63 and will put those on as soon as they get here and see if that clears the cyl test. I'm stumped until then so will hope I get some input here guys anything is appreciated i'm gonna be really bummed if I cant get my baby on the road and enjoy some top down driving before the winter, thank you everyone for your help

Your compression test results look OK.

The TPS dropout at 3.3 volts would cause problems at more that 1/2 throttle. If it does it with both TPS sensors, you have a wiring problem or a problem with the tang on the throttle shaft that engages the TPS sensor. If it only does it with only one sensor, that sensor probably has a bad spot in the sensor element.

Code 15 - No Keep Alive Memory power to PCM pin 1 or bad PCM (Memory Test

Failure). The voltage to the Keep Alive Memory (KAM) is missing (wiring problem) or the KAM is bad. The KAM holds all of the settings that the computer "learns" as it operates and all the stored error codes that are generated as a result of something malfunctioning while the engine is running. Use a voltmeter to check the voltage to the pin 1 on the computer - you should always have 12 volts. No constant 12 volts = bad wiring. If you do always have the 12 volts, then the KAM is bad and the computer is faulty.

If the computer has to "relearn" all the optimum settings every time it powers up, the initial 5-30 minutes of operation may exhibit surges, poor low speed performance, and rough idle.

Note that some aftermarket chips will cause code 15 to set. Remove the chip, clear the codes and retest.

Before replacing the computer, remove the battery ground cable for about 20 minutes. This will clear all the codes. Retest after several days of running. If the 15 code is gone, then don't worry about it. If it is still there, then you get to do some troubleshooting.

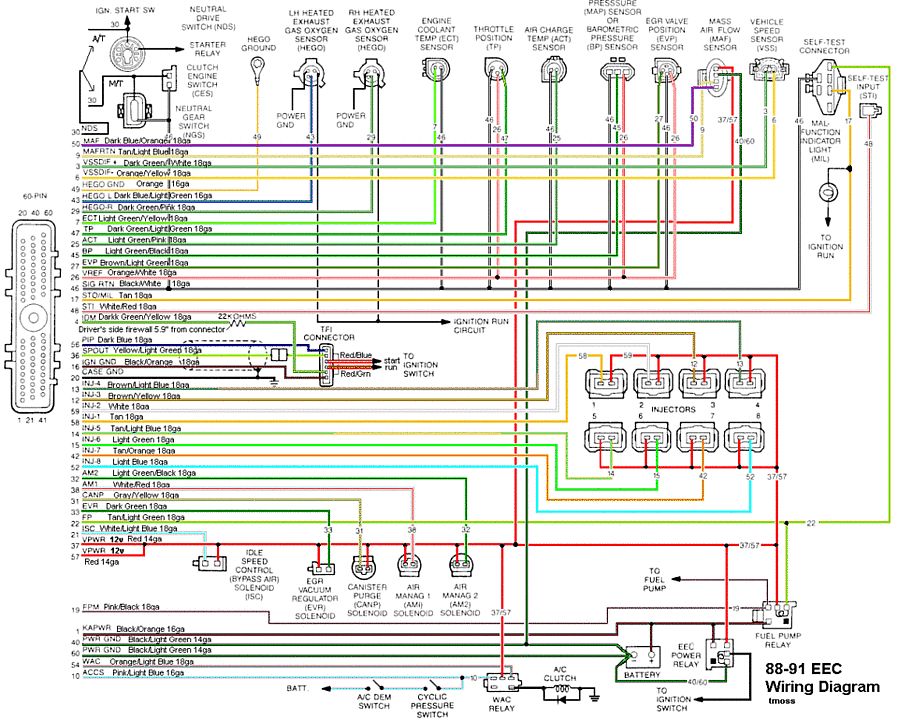

Diagram courtesy of Tmoss & Stang&2birds

Code 85 carbon canister - If the solenoid is not present, check the vacuum connections very carefully. vacuum leaks from the old hose and pluming may cause problems. Make sure that the vacuum line coming from the intake manifold is pugged or capped with a tight fitting, leak free plug or cap.

Code 85 - CANP solenoid - The Carbon Canister solenoid is inoperative or missing. Check vacuum lines for leaks and cracks. Check electrical wiring for loose connections, damaged wiring and insulation. Check solenoid valve operation by grounding the gray/yellow wire to the solenoid and blowing through it.

The computer provides the ground for the solenoid. The red wire to the solenoid is always energized any time the ignition switch is in the run position.

Charcoal canister plumbing - one 3/8" tube from the bottom of the upper manifold to the rubber hose. Rubber hose connects to one side of the canister solenoid valve. Other side of the solenoid valve connects to one side of the canister. The other side of the canister connects to a rubber hose that connects to a line that goes all the way back to the gas tank. There is an electrical connector coming from the passenger side injector harness near #1 injector that plugs into the canister solenoid valve. It's purpose is to vent the gas tank. The solenoid valve opens at cruse to provide some extra fuel. The canister is normally mounted on the passenger side frame rail near the smog pump pulley.

It does not weigh but a pound or so and helps richen up the cruse mixture. It draws no HP & keeps the car from smelling like gasoline in a closed garage. So with all these good things and no bad ones, why not hook it up & use it?

The purge valve solenoid connector is a dangling wire that is near the ECT sensor and oil filler on the passenger side rocker cover. The actual solenoid valve is down next to the carbon canister. There is about 12"-16" of wire that runs parallel to the canister vent hose that comes off the bottom side of the upper intake manifold. That hose connects one port of the solenoid valve; the other port connects to the carbon canister.

The purge valve solenoid should be available at your local auto parts store.

Purge valve solenoid:

The carbon canister is normally mounted on the passenger side frame rail near the smog pump pulley.

Carbon Canister:

See the following website for some help from Tmoss (diagram designer) & Stang&2

Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

The TPS dropout at 3.3 volts would cause problems at more that 1/2 throttle. If it does it with both TPS sensors, you have a wiring problem or a problem with the tang on the throttle shaft that engages the TPS sensor. If it only does it with only one sensor, that sensor probably has a bad spot in the sensor element.

Code 15 - No Keep Alive Memory power to PCM pin 1 or bad PCM (Memory Test

Failure). The voltage to the Keep Alive Memory (KAM) is missing (wiring problem) or the KAM is bad. The KAM holds all of the settings that the computer "learns" as it operates and all the stored error codes that are generated as a result of something malfunctioning while the engine is running. Use a voltmeter to check the voltage to the pin 1 on the computer - you should always have 12 volts. No constant 12 volts = bad wiring. If you do always have the 12 volts, then the KAM is bad and the computer is faulty.

If the computer has to "relearn" all the optimum settings every time it powers up, the initial 5-30 minutes of operation may exhibit surges, poor low speed performance, and rough idle.

Note that some aftermarket chips will cause code 15 to set. Remove the chip, clear the codes and retest.

Before replacing the computer, remove the battery ground cable for about 20 minutes. This will clear all the codes. Retest after several days of running. If the 15 code is gone, then don't worry about it. If it is still there, then you get to do some troubleshooting.

Diagram courtesy of Tmoss & Stang&2birds

Code 85 carbon canister - If the solenoid is not present, check the vacuum connections very carefully. vacuum leaks from the old hose and pluming may cause problems. Make sure that the vacuum line coming from the intake manifold is pugged or capped with a tight fitting, leak free plug or cap.

Code 85 - CANP solenoid - The Carbon Canister solenoid is inoperative or missing. Check vacuum lines for leaks and cracks. Check electrical wiring for loose connections, damaged wiring and insulation. Check solenoid valve operation by grounding the gray/yellow wire to the solenoid and blowing through it.

The computer provides the ground for the solenoid. The red wire to the solenoid is always energized any time the ignition switch is in the run position.

Charcoal canister plumbing - one 3/8" tube from the bottom of the upper manifold to the rubber hose. Rubber hose connects to one side of the canister solenoid valve. Other side of the solenoid valve connects to one side of the canister. The other side of the canister connects to a rubber hose that connects to a line that goes all the way back to the gas tank. There is an electrical connector coming from the passenger side injector harness near #1 injector that plugs into the canister solenoid valve. It's purpose is to vent the gas tank. The solenoid valve opens at cruse to provide some extra fuel. The canister is normally mounted on the passenger side frame rail near the smog pump pulley.

It does not weigh but a pound or so and helps richen up the cruse mixture. It draws no HP & keeps the car from smelling like gasoline in a closed garage. So with all these good things and no bad ones, why not hook it up & use it?

The purge valve solenoid connector is a dangling wire that is near the ECT sensor and oil filler on the passenger side rocker cover. The actual solenoid valve is down next to the carbon canister. There is about 12"-16" of wire that runs parallel to the canister vent hose that comes off the bottom side of the upper intake manifold. That hose connects one port of the solenoid valve; the other port connects to the carbon canister.

The purge valve solenoid should be available at your local auto parts store.

Purge valve solenoid:

The carbon canister is normally mounted on the passenger side frame rail near the smog pump pulley.

Carbon Canister:

See the following website for some help from Tmoss (diagram designer) & Stang&2

Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Last edited:

Ok thanks for the info and diagrams I will check for 12v at pin 1 on the computer if that is ok I guess I can assume the code 15 is due to the chip, but should that code eventually clear? If it doesn't based on the info listed it will have to re learn with every startup and that sounds like it will always have idle issues. Maybe the chip is programmed to handle this? Also on the TPS the voltage drop is def on both sensors but do you think that would cause a WOT hesitation and rough idle? Thanks again for the help going to a shop is my last resortYour compression test results look OK.

The TPS dropout at 3.3 volts would cause problems at more that 1/2 throttle. If it does it with both TPS sensors, you have a wiring problem or a problem with the tang on the throttle shaft that engages the TPS sensor. If it only does it with only one sensor, that sensor probably has a bad spot in the sensor element.

Code 15 - No Keep Alive Memory power to PCM pin 1 or bad PCM (Memory Test

Failure). The voltage to the Keep Alive Memory (KAM) is missing (wiring problem) or the KAM is bad. The KAM holds all of the settings that the computer "learns" as it operates and all the stored error codes that are generated as a result of something malfunctioning while the engine is running. Use a voltmeter to check the voltage to the pin 1 on the computer - you should always have 12 volts. No constant 12 volts = bad wiring. If you do always have the 12 volts, then the KAM is bad and the computer is faulty.

If the computer has to "relearn" all the optimum settings every time it powers up, the initial 5-30 minutes of operation may exhibit surges, poor low speed performance, and rough idle.

Note that some aftermarket chips will cause code 15 to set. Remove the chip, clear the codes and retest.

Before replacing the computer, remove the battery ground cable for about 20 minutes. This will clear all the codes. Retest after several days of running. If the 15 code is gone, then don't worry about it. If it is still there, then you get to do some troubleshooting.

Diagram courtesy of Tmoss & Stang&2birds

Code 85 carbon canister - If the solenoid is not present, check the vacuum connections very carefully. vacuum leaks from the old hose and pluming may cause problems. Make sure that the vacuum line coming from the intake manifold is pugged or capped with a tight fitting, leak free plug or cap.

Code 85 - CANP solenoid - The Carbon Canister solenoid is inoperative or missing. Check vacuum lines for leaks and cracks. Check electrical wiring for loose connections, damaged wiring and insulation. Check solenoid valve operation by grounding the gray/yellow wire to the solenoid and blowing through it.

The computer provides the ground for the solenoid. The red wire to the solenoid is always energized any time the ignition switch is in the run position.

Charcoal canister plumbing - one 3/8" tube from the bottom of the upper manifold to the rubber hose. Rubber hose connects to one side of the canister solenoid valve. Other side of the solenoid valve connects to one side of the canister. The other side of the canister connects to a rubber hose that connects to a line that goes all the way back to the gas tank. There is an electrical connector coming from the passenger side injector harness near #1 injector that plugs into the canister solenoid valve. It's purpose is to vent the gas tank. The solenoid valve opens at cruse to provide some extra fuel. The canister is normally mounted on the passenger side frame rail near the smog pump pulley.

It does not weigh but a pound or so and helps richen up the cruse mixture. It draws no HP & keeps the car from smelling like gasoline in a closed garage. So with all these good things and no bad ones, why not hook it up & use it?

The purge valve solenoid connector is a dangling wire that is near the ECT sensor and oil filler on the passenger side rocker cover. The actual solenoid valve is down next to the carbon canister. There is about 12"-16" of wire that runs parallel to the canister vent hose that comes off the bottom side of the upper intake manifold. That hose connects one port of the solenoid valve; the other port connects to the carbon canister.

The purge valve solenoid should be available at your local auto parts store.

Purge valve solenoid:

The carbon canister is normally mounted on the passenger side frame rail near the smog pump pulley.

Carbon Canister:

See the following website for some help from Tmoss (diagram designer) & Stang&2

Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Micheal Nadeau

Active Member

If you have 12V to pin 1, then replacing the computer will fix your code 15 issue. So you wont always have idle surge issues, unless some other problem were to arise later down the road.

Both TPS sensors with the same problem sounds odd. Check the engagement of the sensor with the tang on the throttle shaft. If you purchased the TPS sensors from a local merchant , return them if they have a warranty. Then go buy a TPS sensor from another store not affiliated with the one you made the first TPS purchase from. That eliminates getting another one of the bad sensors from the same batch.Ok thanks for the info and diagrams I will check for 12v at pin 1 on the computer if that is ok I guess I can assume the code 15 is due to the chip, but should that code eventually clear? If it doesn't based on the info listed it will have to re learn with every startup and that sounds like it will always have idle issues. Maybe the chip is programmed to handle this? Also on the TPS the voltage drop is def on both sensors but do you think that would cause a WOT hesitation and rough idle? Thanks again for the help going to a shop is my last resort

The code 15 will remain if it is due to an aftermarket chip. It never goes away as long as the chip is in place. Disconnect the battery, remove the chip. reconnect the battery, and see if the idle changes. If it improves, the chip is the problem.

The code 15 won't clear if there is no voltage on pin 1 or a problem with the computer's stored memory. In those 2 cases, the computer will have to relearn the settings every time you shut off the engine. That can cause idle and performance problems until the computer relearns the settings. The process starts all over again when you shut down. the engine..

Yeah that's what I figure but what I'm thinking is if I have 12v to pin 1 then my SCT chip is most likely causing the code 15 then what? I'm going to test pin 1 tomorrow and if it's good I will take the chip out and run it like that for a few days and see if that clears the codes and helps with the idle if so then I will have to contact SCT and see if they have peramiters in the chip to deal with that. I did have the chip out for a few days and the idle was a bit lower and smoother not where it shld be but didn't drive it much and didn't ck to see if code 15 was still comming up. According to SCT the chip will cause a higher idle possibly exaggerating an idle issue. Thanks for the inputIf you have 12V to pin 1, then replacing the computer will fix your code 15 issue. So you wont always have idle surge issues, unless some other problem were to arise later down the road.

Yes igree that both TPS's are having the same drop in voltage is odd, the original one on there is a BBK that I had on the engine before the top half build and now I purchased a Professional Products and that's what's on there now I will check the shaft and go through the terminal on the computer and see where that takes me and try removing the chip again as well the last time I took the chip out the idle was lower and the idle seemed smoother but still was not stable but will give it a go again. According to SCT the idle will bump up with the chip but shouldn't cause an idle issue! will prob do this tomorrow and post my findings then. Thanks againBoth TPS sensors with the same problem sounds odd. Check the engagement of the sensor with the tang on the throttle shaft. If you purchased the TPS sensors from a local merchant , return them if they have a warranty. Then go buy a TPS sensor from another store not affiliated with the one you made the first TPS purchase from. That eliminates getting another one of the bad sensors from the same batch.

The code 15 will remain if it is due to an aftermarket chip. It never goes away as long as the chip is in place. Disconnect the battery, remove the chip. reconnect the battery, and see if the idle changes. If it improves, the chip is the problem.

The code 15 won't clear if there is no voltage on pin 1 or a problem with the computer's stored memory. In those 2 cases, the computer will have to relearn the settings every time you shut off the engine. That can cause idle and performance problems until the computer relearns the settings. The process starts all over again when you shut down. the engine..

Yes igree that both TPS's are having the same drop in voltage is odd, the original one on there is a BBK that I had on the engine before the top half build and now I purchased a Professional Products and that's what's on there now I will check the shaft and go through the terminal on the computer and see where that takes me and try removing the chip again as well the last time I took the chip out the idle was lower and the idle seemed smoother but still was not stable but will give it a go again. According to SCT the idle will bump up with the chip but shouldn't cause an idle issue! will prob do this tomorrow and post my findings then. Thanks again

Both TPS sensors with the same problem sounds odd. Check the engagement of the sensor with the tang on the throttle shaft. If you purchased the TPS sensors from a local merchant , return them if they have a warranty. Then go buy a TPS sensor from another store not affiliated with the one you made the first TPS purchase from. That eliminates getting another one of the bad sensors from the same batch.

The code 15 will remain if it is due to an aftermarket chip. It never goes away as long as the chip is in place. Disconnect the battery, remove the chip. reconnect the battery, and see if the idle changes. If it improves, the chip is the problem.

The code 15 won't clear if there is no voltage on pin 1 or a problem with the computer's stored memory. In those 2 cases, the computer will have to relearn the settings every time you shut off the engine. That can cause idle and performance problems until the computer relearns the settings. The process starts all over again when you shut down. the engine..

Both TPS sensors with the same problem sounds odd. Check the engagement of the sensor with the tang on the throttle shaft. If you purchased the TPS sensors from a local merchant , return them if they have a warranty. Then go buy a TPS sensor from another store not affiliated with the one you made the first TPS purchase from. That eliminates getting another one of the bad sensors from the same batch.

The code 15 will remain if it is due to an aftermarket chip. It never goes away as long as the chip is in place. Disconnect the battery, remove the chip. reconnect the battery, and see if the idle changes. If it improves, the chip is the problem.

The code 15 won't clear if there is no voltage on pin 1 or a problem with the computer's stored memory. In those 2 cases, the computer will have to relearn the settings every time you shut off the engine. That can cause idle and performance problems until the computer relearns the settings. The process starts all over again when you shut down. the engine..

OK sorry its been a while but really have not had any time for the fox but this is what I have since the last posts. I checked the tps tang on the throttle body and all is good. The tps still has that momentary drop at 3.3 ish volts which im still puzzled at , I have the stock motorcraft distributor in with the motorcraft tfi set a t 10 deg timing, I did take the chip out and cleaned the contacts and rinstalled but while the chip was out the codes 15 is gone and I get the code 11. With the chip in I still get the code 15 and no code 11, this is KOEO. I had to recontact Bama and they are supposedly working on a few modifications to the chip, but they lost all my info so had to resend and now waiting to hear from them. I have been driving the car back and forth to work and have noticed the following. Cold start is fine and runs good for about 2 min then idle surges 100 rpm maybe 150 rpm, then while driving I notice that when the car is up to temp 185 deg or so and I come to a stop, the car has a slight surge for a second then smooths out and is fine. When I got home and parked in the garage the idle was perfect, so I'm really thinking the car is relearning and needs full temp and 20 min of driving to relearn, but there is still a flat spot in the throttle when I goose it. I'm starting to think the car is a little lean considering the exhaust is not overly rich at idle and with the chip on the most aggressive setting. When I pulled the plugs they had a slight whiting on them not coffee colored, so I'm considering putting a adjustable FP regulator on which I already have one and see if I can bump the pressure up a tad at idle and see if that makes any difference in the hesitation. I may also try to adj the timing to 12 or 14 and see if that has any effect but I doubt it will. I'm going to try get in the garage tomorrow and tinker a bit and will update as soon as I can.also will update when I hear from Bama. I have to say the car is an animal with the intake and heads on there and very happy with her, and i'm really hoping I can pull this together and have it totally resolved soon. Thanks for all the help and any more input is always welcome

, I have the stock motorcraft distributor in with the motorcraft tfi set a t 10 deg timing, I did take the chip out and cleaned the contacts and rinstalled but while the chip was out the codes 15 is gone and I get the code 11. With the chip in I still get the code 15 and no code 11, this is KOEO. I had to recontact Bama and they are supposedly working on a few modifications to the chip, but they lost all my info so had to resend and now waiting to hear from them. I have been driving the car back and forth to work and have noticed the following. Cold start is fine and runs good for about 2 min then idle surges 100 rpm maybe 150 rpm, then while driving I notice that when the car is up to temp 185 deg or so and I come to a stop, the car has a slight surge for a second then smooths out and is fine. When I got home and parked in the garage the idle was perfect, so I'm really thinking the car is relearning and needs full temp and 20 min of driving to relearn, but there is still a flat spot in the throttle when I goose it. I'm starting to think the car is a little lean considering the exhaust is not overly rich at idle and with the chip on the most aggressive setting. When I pulled the plugs they had a slight whiting on them not coffee colored, so I'm considering putting a adjustable FP regulator on which I already have one and see if I can bump the pressure up a tad at idle and see if that makes any difference in the hesitation. I may also try to adj the timing to 12 or 14 and see if that has any effect but I doubt it will. I'm going to try get in the garage tomorrow and tinker a bit and will update as soon as I can.also will update when I hear from Bama. I have to say the car is an animal with the intake and heads on there and very happy with her, and i'm really hoping I can pull this together and have it totally resolved soon. Thanks for all the help and any more input is always welcome

, I have the stock motorcraft distributor in with the motorcraft tfi set a t 10 deg timing, I did take the chip out and cleaned the contacts and rinstalled but while the chip was out the codes 15 is gone and I get the code 11. With the chip in I still get the code 15 and no code 11, this is KOEO. I had to recontact Bama and they are supposedly working on a few modifications to the chip, but they lost all my info so had to resend and now waiting to hear from them. I have been driving the car back and forth to work and have noticed the following. Cold start is fine and runs good for about 2 min then idle surges 100 rpm maybe 150 rpm, then while driving I notice that when the car is up to temp 185 deg or so and I come to a stop, the car has a slight surge for a second then smooths out and is fine. When I got home and parked in the garage the idle was perfect, so I'm really thinking the car is relearning and needs full temp and 20 min of driving to relearn, but there is still a flat spot in the throttle when I goose it. I'm starting to think the car is a little lean considering the exhaust is not overly rich at idle and with the chip on the most aggressive setting. When I pulled the plugs they had a slight whiting on them not coffee colored, so I'm considering putting a adjustable FP regulator on which I already have one and see if I can bump the pressure up a tad at idle and see if that makes any difference in the hesitation. I may also try to adj the timing to 12 or 14 and see if that has any effect but I doubt it will. I'm going to try get in the garage tomorrow and tinker a bit and will update as soon as I can.also will update when I hear from Bama. I have to say the car is an animal with the intake and heads on there and very happy with her, and i'm really hoping I can pull this together and have it totally resolved soon. Thanks for all the help and any more input is always welcome

, I have the stock motorcraft distributor in with the motorcraft tfi set a t 10 deg timing, I did take the chip out and cleaned the contacts and rinstalled but while the chip was out the codes 15 is gone and I get the code 11. With the chip in I still get the code 15 and no code 11, this is KOEO. I had to recontact Bama and they are supposedly working on a few modifications to the chip, but they lost all my info so had to resend and now waiting to hear from them. I have been driving the car back and forth to work and have noticed the following. Cold start is fine and runs good for about 2 min then idle surges 100 rpm maybe 150 rpm, then while driving I notice that when the car is up to temp 185 deg or so and I come to a stop, the car has a slight surge for a second then smooths out and is fine. When I got home and parked in the garage the idle was perfect, so I'm really thinking the car is relearning and needs full temp and 20 min of driving to relearn, but there is still a flat spot in the throttle when I goose it. I'm starting to think the car is a little lean considering the exhaust is not overly rich at idle and with the chip on the most aggressive setting. When I pulled the plugs they had a slight whiting on them not coffee colored, so I'm considering putting a adjustable FP regulator on which I already have one and see if I can bump the pressure up a tad at idle and see if that makes any difference in the hesitation. I may also try to adj the timing to 12 or 14 and see if that has any effect but I doubt it will. I'm going to try get in the garage tomorrow and tinker a bit and will update as soon as I can.also will update when I hear from Bama. I have to say the car is an animal with the intake and heads on there and very happy with her, and i'm really hoping I can pull this together and have it totally resolved soon. Thanks for all the help and any more input is always welcomeoops IDK how I botched that before yup i'm still a newbie sorry

Similar threads

- Replies

- 2

- Views

- 299

- Replies

- 12

- Views

- 682

- Replies

- 25

- Views

- 2K

- Replies

- 3

- Views

- 312