stang89bidges

Advanced Member

I subscribe to LMR YouTube channel. This just posted recently. Very interesting. Never seen this method performed before.

View: https://youtu.be/5MjAxnGeGKw

View: https://youtu.be/5MjAxnGeGKw

Hard to say if the exhaust leak is bad enough to pop or if you have a timing issue. Do you happen to have the dizzy one tooth off?

This doesn’t prove that the block is HO. Some trucks evidently use a HO firing order

with a low lift cam. However, it will definitely prove that a block can’t be HO because the firing order is wrong.

Remove the #1 & #3 spark plugs. Put your finger in #1 spark plug hole. Crank the engine over until you feel compression on #1 cylinder. Slowly turn the engine until the TDC mark and the timing pointer line up. Mark TDC on the balancer with chalk or paint. Put your finger in #3 spark plug hole and crank the engine 90 degrees. You should feel pressure trying to blow past your finger. If you do not feel pressure, repeat the process again. If you feel pressure, it is a HO engine.

No pressure the second time, remove spark plug #5. Put your finger in #1 spark plug hole. Crank the engine over until you feel compression on #1 cylinder. Put your finger in #5 spark plug hole and crank the engine 90 degrees. If you feel pressure now, the engine is not a HO model, no matter what it says on the engine.

Using a small carpenter or machinist square to mark the harmonic balancer off into 90 degree sections may be helpful here.

A 15/16 deep socket & breaker bar or ratchet may be used to turn the engine.

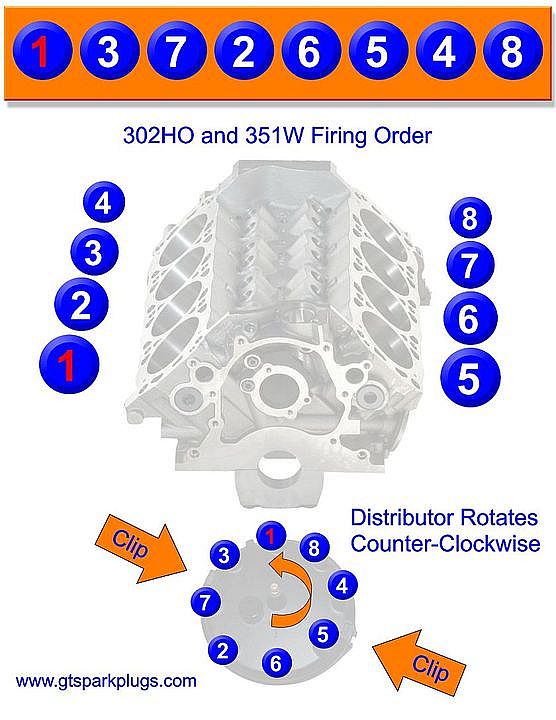

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8

Thanks! I'm just going to ignore the po's markings and do this and it should be done rightCorrect....and your car should have the ho firing order...all mustangs do.

If your redoing everything that should work lol. Never thought about it that way...

Firing order will be your necessary constant.

And watch the 2 dist cap brackets and TFI module. You want those free of any obstacles so you can spin the dizzy comfortably during timing the engine.