I cant seem to hit torque after hitting 0 lash.... after 4 turns even... getting pissed... any ideas

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pushrod Problems

- Thread starter Adam95GT

- Start date

-

Sponsors (?)

with ped mout heads you have to tighten to 24lb's of torque IIRC.... And hit it in less then 1 turn... i just am getting confused with trying to get these rocker arms on........

blksn955.o

Founding Member

Are they the correct PR?

If the PR is too long you will reach 0 lash before the rocker bolt is anywere near were it should be.

To find out quickly, try a shim or two under the rocker if it raises up the rocker enough the PR may be too long.

However, with the shims you use them to get the rocker to have the correct travel over the valve head. You should NOT use a shim to make a PR work.

The correct PR is the one that gives you the preload you looking for with the rocker with the correct shims (or no shims) that give the rocker the shortest travel that is as close to the middle of the valve head as possible.

If the PR is too long you will reach 0 lash before the rocker bolt is anywere near were it should be.

To find out quickly, try a shim or two under the rocker if it raises up the rocker enough the PR may be too long.

However, with the shims you use them to get the rocker to have the correct travel over the valve head. You should NOT use a shim to make a PR work.

The correct PR is the one that gives you the preload you looking for with the rocker with the correct shims (or no shims) that give the rocker the shortest travel that is as close to the middle of the valve head as possible.

well when we tighten down the nut it depresses the spring and thats whats going on.... ive noticed there are shims under the pedestals already however...

blksn955.o

Founding Member

nut? do you have pedistal or stud mount rockers?

or do you mean nut as in bolt with a head on it?

if it is depressing the spring a few things can be happening.

1. the engine is not at compression TDC for that cyl. when your trq. them down.

2. the rocker roller tip is not clearing your springs and pushing them down as it is not making contact with the valve head.

or do you mean nut as in bolt with a head on it?

if it is depressing the spring a few things can be happening.

1. the engine is not at compression TDC for that cyl. when your trq. them down.

2. the rocker roller tip is not clearing your springs and pushing them down as it is not making contact with the valve head.

PUNISHER RACING

Active Member

you mean it is pushing the valve spring down as you tighten the bolt? if so put that valve on the cams base circle first.

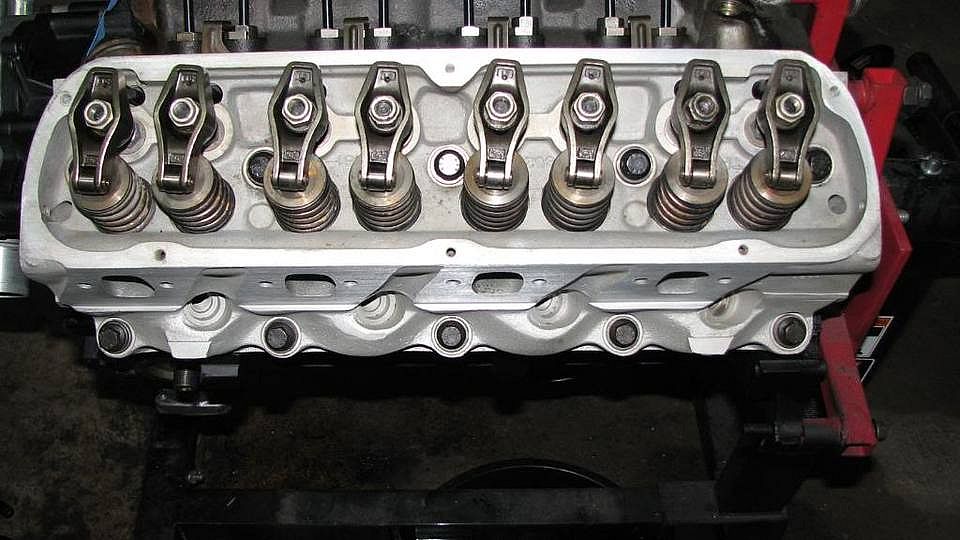

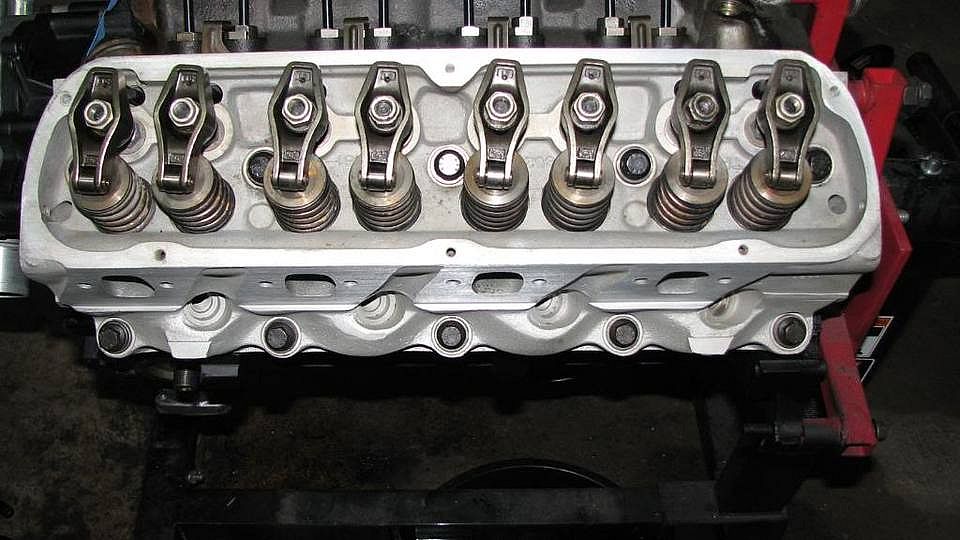

Maybe this will help, this is the rocker setup. TFS hi-ports, I think the P/R is 6.7 but I can re-check that, B-cam style cam

What we are doing:

1. Snug up all rocker arm nuts until the pushrod is not restricted but there is no super obvious wobbling around of the rocker arm

2. Bring cylinder 1 (driver side head nearest front of motor...water pump) until exhaust valve just begins to open by watching p/r and lifter...this should be the base cam circle on the intake valve. we make sure we're working on the intake valve (the back of the two) by looking into the intake port on number one, seeing the valve, and then using that rocker arm.

3. all but one pedestal as pictured has a .030" shim (our guess, there are two sizes shims come in, but I did not measure it, one has an extra shim that is twice as thick as these ones, which is why we think that one has a .030 and a .060 on it).

4. tighten the rocker arm nut until the pushrod begins to feel a little restriction on it. this is zero lash.

5. we are trying to torque to 24 ft.lbs, it should come between 1/4 and 1 rotation for a street motor. we were told that if it comes in any less, we have too long a pushrod. we were told that if it comes in any more than 1 turn, we need shims below the pedestal. we found literature that said each .030" shim would compensate for one half turn. we are measuring turns by putting the torque wrench in the 12 o clock position and rotating clockwise 360 degrees, not using the ratcheting motion.

What is happening:

we go around the first time. still no click from the torque wrench. it is set correctly and it works fine as tested on other hardware. we go around another 360 degrees. still have not reached torque. now we are worried because that would mean we need at least two .060" shims on top of the .030" one we have now.

so we keep going. three turns. four turns. by the third and the fourth turn, the rocker arm is actually moving in such a way that instead of reaching the torque spec, it is actually depressing the stem of the valve and opening the valve. these are double valve springs, they should offer a lot of resistance.

my theory is we do not have long enough pushrods and we need an adjustable pushrod to check, but it's a pure guess. does anyone have the old procedure with a feeler gauge on hand?

by the way, that one cylinder with a .060 and a .030 on it...we tried that one too just to see...it does the same thing...by four turns we have not reached the torque spec and the valve is just opening more and more. there is so much thread on the pedestal I do not understand what is supposed to stop the nut from turning, it just keeps threading down further. we had two other pushrods, one stock 5.0 one and one slightly shorter than the tfs pushrods we are using, there was no difference with either of them.

What we are doing:

1. Snug up all rocker arm nuts until the pushrod is not restricted but there is no super obvious wobbling around of the rocker arm

2. Bring cylinder 1 (driver side head nearest front of motor...water pump) until exhaust valve just begins to open by watching p/r and lifter...this should be the base cam circle on the intake valve. we make sure we're working on the intake valve (the back of the two) by looking into the intake port on number one, seeing the valve, and then using that rocker arm.

3. all but one pedestal as pictured has a .030" shim (our guess, there are two sizes shims come in, but I did not measure it, one has an extra shim that is twice as thick as these ones, which is why we think that one has a .030 and a .060 on it).

4. tighten the rocker arm nut until the pushrod begins to feel a little restriction on it. this is zero lash.

5. we are trying to torque to 24 ft.lbs, it should come between 1/4 and 1 rotation for a street motor. we were told that if it comes in any less, we have too long a pushrod. we were told that if it comes in any more than 1 turn, we need shims below the pedestal. we found literature that said each .030" shim would compensate for one half turn. we are measuring turns by putting the torque wrench in the 12 o clock position and rotating clockwise 360 degrees, not using the ratcheting motion.

What is happening:

we go around the first time. still no click from the torque wrench. it is set correctly and it works fine as tested on other hardware. we go around another 360 degrees. still have not reached torque. now we are worried because that would mean we need at least two .060" shims on top of the .030" one we have now.

so we keep going. three turns. four turns. by the third and the fourth turn, the rocker arm is actually moving in such a way that instead of reaching the torque spec, it is actually depressing the stem of the valve and opening the valve. these are double valve springs, they should offer a lot of resistance.

my theory is we do not have long enough pushrods and we need an adjustable pushrod to check, but it's a pure guess. does anyone have the old procedure with a feeler gauge on hand?

by the way, that one cylinder with a .060 and a .030 on it...we tried that one too just to see...it does the same thing...by four turns we have not reached the torque spec and the valve is just opening more and more. there is so much thread on the pedestal I do not understand what is supposed to stop the nut from turning, it just keeps threading down further. we had two other pushrods, one stock 5.0 one and one slightly shorter than the tfs pushrods we are using, there was no difference with either of them.

Attachments

-

adammotor004.jpg83.1 KB · Views: 68

adammotor004.jpg83.1 KB · Views: 68 -

adammotor008.jpg76.4 KB · Views: 71

adammotor008.jpg76.4 KB · Views: 71 -

adammotor009.jpg68 KB · Views: 63

adammotor009.jpg68 KB · Views: 63 -

adammotor007.jpg61 KB · Views: 65

adammotor007.jpg61 KB · Views: 65 -

adammotor006.jpg78.2 KB · Views: 60

adammotor006.jpg78.2 KB · Views: 60 -

adammotor005.jpg80.8 KB · Views: 56

adammotor005.jpg80.8 KB · Views: 56 -

adammotor011.jpg72.7 KB · Views: 54

adammotor011.jpg72.7 KB · Views: 54 -

adammotor013.jpg69.5 KB · Views: 66

adammotor013.jpg69.5 KB · Views: 66 -

adammotor026.jpg83.8 KB · Views: 73

adammotor026.jpg83.8 KB · Views: 73 -

adammotor024.jpg64 KB · Views: 69

adammotor024.jpg64 KB · Views: 69 -

adammotor025.jpg63.3 KB · Views: 59

adammotor025.jpg63.3 KB · Views: 59

damn chris... that about says it all thanks man... im gonna post another thread about the other problem send the pics and videos to [email protected]

thanks man....

With the other problem... did you notice if it was making that noise when we pulled the ditsy... if so i think the oil pump is ruled out...

thanks man....

With the other problem... did you notice if it was making that noise when we pulled the ditsy... if so i think the oil pump is ruled out...

blksn955.o

Founding Member

I may be wrong but those look like stud mounts. Unless the rocker combo your running is funky....

If your running stud mounts get some poly locks and read up on how to setup stud mount rockers. It is very different than pedistal...and a much better way to go IMHO.

If your running stud mounts get some poly locks and read up on how to setup stud mount rockers. It is very different than pedistal...and a much better way to go IMHO.

Also.... they ate 6.725 push rods i think or something along thoes lines... with comp. pro magnium 1.6rr's

More info on the rockers

http://www.compcams.com/Technical/Products/RockerArms/MagnumRoller.asp

mine are the rail type...

http://www.compcams.com/Technical/Products/RockerArms/MagnumRoller.asp

mine are the rail type...

Maryland Stang

Active Member

It's not a pedestal setup, it's stud mount. You need pushrod guide plates and hardened pushrods to begin with.

adam, after looking at this picture

http://static.summitracing.com/global/images/prod/large/crn-36655-16.jpg

it is part number CRN-36655-16 on summit racing

I think he is right.

And this is difficulty is why I'm keeping my 4V...

MarylandStang...would you suggest trying to find the pushrod guide plates and making what we have work or just spending the ~$95 on this kit (plus p/r) and starting over with a new stud kit and instruction manual? or is there another stud kit you would recommend?

adam, another picture, he is right

http://cgi.ebay.com/ebaymotors/ARP-...-Kit-7-16_W0QQitemZ110215406179QQcmdZViewItem

http://static.summitracing.com/global/images/prod/large/crn-36655-16.jpg

it is part number CRN-36655-16 on summit racing

I think he is right.

And this is difficulty is why I'm keeping my 4V...

MarylandStang...would you suggest trying to find the pushrod guide plates and making what we have work or just spending the ~$95 on this kit (plus p/r) and starting over with a new stud kit and instruction manual? or is there another stud kit you would recommend?

adam, another picture, he is right

http://cgi.ebay.com/ebaymotors/ARP-...-Kit-7-16_W0QQitemZ110215406179QQcmdZViewItem

damn that sucks... at least its under $100.... well that other engine was more of a peice then we had origionaly thought then!

pushrod guide plates...

http://store.summitracing.com/partdetail.asp?part=CCA-4818-8&autoview=sku

http://cgi.ebay.com/ebaymotors/Comp...183560541QQcmdZViewItem?hash=item180183560541

???

pushrod guide plates...

http://store.summitracing.com/partdetail.asp?part=CCA-4818-8&autoview=sku

http://cgi.ebay.com/ebaymotors/Comp...183560541QQcmdZViewItem?hash=item180183560541

???

divit250r

Member

Those are like the rockers that Ford used before the fulcrum style, the non-adjustable kind from the late 60s. Same style that my dad used on his BB 429. You might be having a problem with the rails on the rockers hitting the retainers and that is a VERY bad situation.  It could pop the keepers out and let a valve drop into the cylinder...

It could pop the keepers out and let a valve drop into the cylinder...

Maybe it's not what it looks like to me, but I'd be worried about that myself. I agree that the best thing to do is get a set of guide plates, roller rockers and poly locks. We tried the nuts with dad's rail rockers and had to adjust them all the time because they wouldn't hold the adjustment setting. If anybody sees something bogus here, feel free to call I'm going from memories that are at least 15 years old. I'm only 30.

I'm going from memories that are at least 15 years old. I'm only 30.

Good luck!

Scott

It could pop the keepers out and let a valve drop into the cylinder...

It could pop the keepers out and let a valve drop into the cylinder...

Maybe it's not what it looks like to me, but I'd be worried about that myself. I agree that the best thing to do is get a set of guide plates, roller rockers and poly locks. We tried the nuts with dad's rail rockers and had to adjust them all the time because they wouldn't hold the adjustment setting. If anybody sees something bogus here, feel free to call

I'm going from memories that are at least 15 years old. I'm only 30.

I'm going from memories that are at least 15 years old. I'm only 30.

Good luck!

Scott

SQUEEZE&STROKE

New Member

Yeah, those are stud mount...you need stud mount rockers, guideplates, and hardened pushrods.

Pull a rocker off and look at the fulcrum. A stud mount rocker will have a flat spot which faces up for the polylocks to sit against. The rest of the fulcrum will be round.

Pull a rocker off and look at the fulcrum. A stud mount rocker will have a flat spot which faces up for the polylocks to sit against. The rest of the fulcrum will be round.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 0

- Views

- 264

- Replies

- 4

- Views

- 405

- Replies

- 14

- Views

- 836

- Replies

- 35

- Views

- 4K