You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Want To Blow 5 Years And $50k On A Foxbody? Step By Step Instructions Inside!

- Thread starter RacEoHolic330

- Start date

-

Sponsors (?)

I got one word for you..............

JJJJJTTTTTTT!!!!!!

Go home Mike, you're drunk.

Adopt me?

You can live in my basement. It's not finished, but the concrete doesn't get too cold in the summer.

I am really digging the hydraulic clutch setup, nice touch there!

It is pretty cool. Hopefully it doesn't give me any problems. Definitely more complex than just a cable, but it was one of those 'had to have' things.

The wiring saga continues. I terminated the battery cables at the front of the car, and got the starter wired up. I'm working on the alternator and ignition wiring next.

Guess what I got done this weekend. Yup, more wiring.

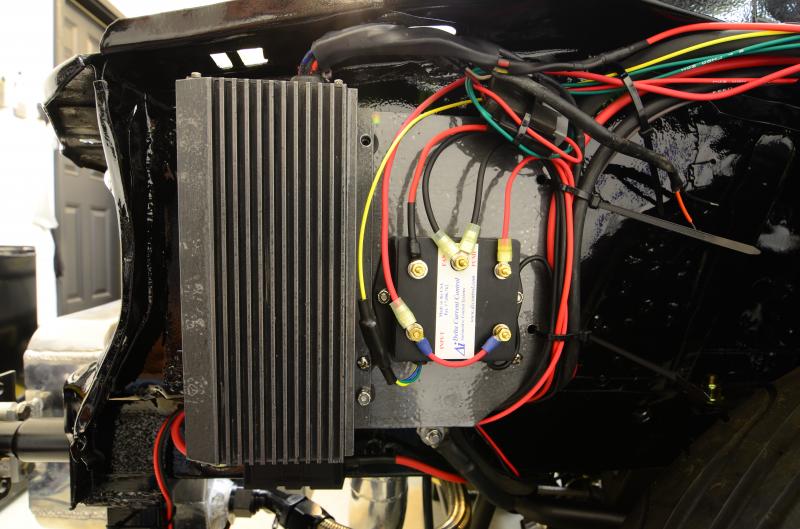

Mounted the ignition box, DCControl module.

The mess of wires outside the car will be all nice and loomed once I'm done running all the wires.

The DCControl doesn't require any relays. Just 12V and ignition. It will automatically control the speed of the water pump and the fan based on the coolant temp. Hopefully it works well.

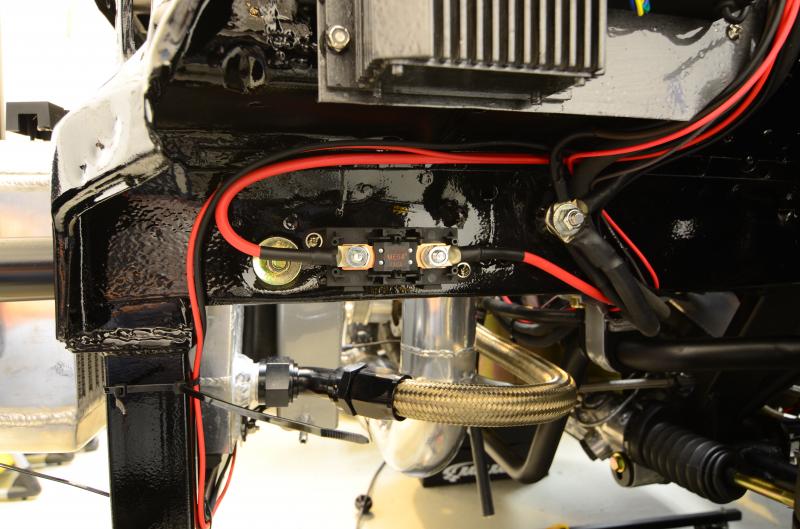

Also wired the alternator. Figured this was a pretty good spot for the fuse. To the right of that is the ground stud that I welded to the frame rail. The negative battery cable runs straight from the battery to the block, and then back to this stud. I also installed a 6ga ground to one of the starter mounting bolts due to the fact that the bellhousing is powdercoated, and I was concerned that there wouldn't be a good ground path for the starter.

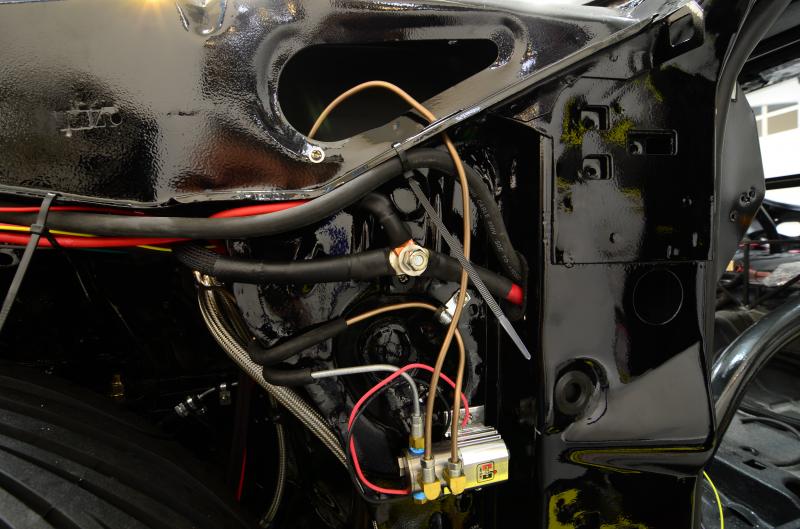

Here's the 1/0 12V battery feed mounted to an insulated stud. Off of that is the starter feed as well as the alternator wire. There is another 6ga wire that goes into the passenger compartment that will be used for all the 12V feeds inside the car.

The starter cable I made with some heat protection on the starter side.

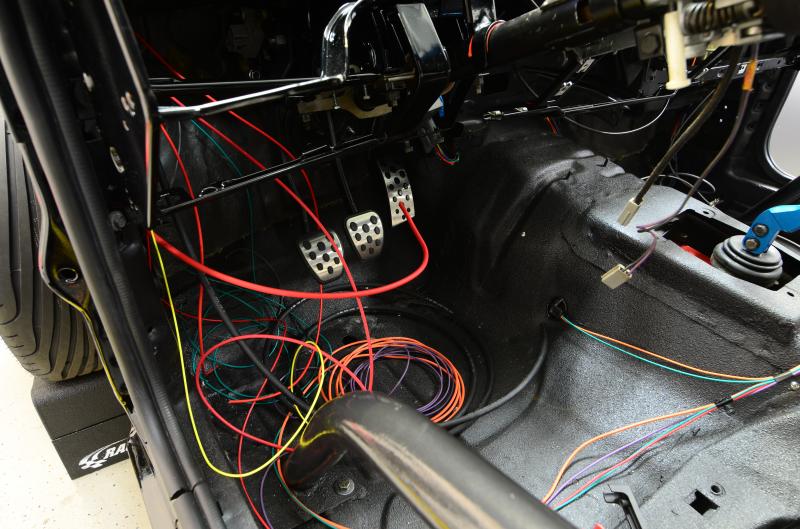

And the interior of the car with the mess of wires coming through the firewall. I need to find a good spot to mount the fuse box.

I'm probably not going to loom any wires until I know everything works. No point in tearing everything apart if I have an issue. Next up will probably be the boost controller and vacuum lines.

Mounted the ignition box, DCControl module.

The mess of wires outside the car will be all nice and loomed once I'm done running all the wires.

The DCControl doesn't require any relays. Just 12V and ignition. It will automatically control the speed of the water pump and the fan based on the coolant temp. Hopefully it works well.

Also wired the alternator. Figured this was a pretty good spot for the fuse. To the right of that is the ground stud that I welded to the frame rail. The negative battery cable runs straight from the battery to the block, and then back to this stud. I also installed a 6ga ground to one of the starter mounting bolts due to the fact that the bellhousing is powdercoated, and I was concerned that there wouldn't be a good ground path for the starter.

Here's the 1/0 12V battery feed mounted to an insulated stud. Off of that is the starter feed as well as the alternator wire. There is another 6ga wire that goes into the passenger compartment that will be used for all the 12V feeds inside the car.

The starter cable I made with some heat protection on the starter side.

And the interior of the car with the mess of wires coming through the firewall. I need to find a good spot to mount the fuse box.

I'm probably not going to loom any wires until I know everything works. No point in tearing everything apart if I have an issue. Next up will probably be the boost controller and vacuum lines.

Last edited:

If I may speak from experience, the wiring is never "done" I thought I had everything wired working and finished on mine. Boy was I wrong. I loomed it all really nice and everything. Once on the dyno there were more features of the fast that needed enabling plus changes that my buddy/tuner wanted me to make in regards to circuit isolation, grounding, etc. My car has a complete floating ground setup and nothing is grounded to the chassis now. Data logger functions that needed different wiring, triggers for the data logger, fan and fuel pump controls, triggers for the launch retard and this is the abridged version of changes. It's not the first car I've ever wired and surely won't be the last but my Ttop car had a learning curve with all of the electronics. I don't me to deter you in anyway but do expect to make at the least a few changes once it's all said and done. Looks great so far!

I hear ya 84. I definitely expect there to be some changes down the road. I'm trying to account for the possibility of added circuits and devices in the future by placing an accessible hot and ground bus under the dash. Changes happen, all part of 'hot rodding' if you ask me!

I'm actually doing somewhat of a hybrid floating ground system for the car. I did ground to the chassis, but every ground on the car will have a path via copper wire back to the battery. I'm not relying on 25 year old steel to provide me a adequate ground path. Grounds are usually ignored and taken for granted. I think the source of most people's EFI problems simply comes from bad grounds.

I'm actually doing somewhat of a hybrid floating ground system for the car. I did ground to the chassis, but every ground on the car will have a path via copper wire back to the battery. I'm not relying on 25 year old steel to provide me a adequate ground path. Grounds are usually ignored and taken for granted. I think the source of most people's EFI problems simply comes from bad grounds.

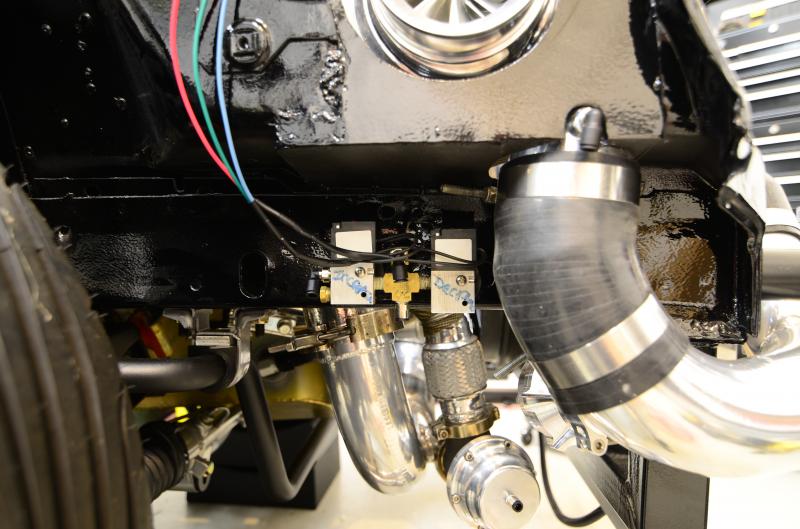

I decided to go ahead and do a leak down test on the fuel system. I installed a cap right before the regulator and a special Schrader valve fitting at the fuel pump. I pressurized the system to about 60psi and watched the tire gauge on the valve. Noticed the needle moving very slowly. I went into the engine bay and could hear a faint hissing. I found one fitting at the feed y-block that was a tad too loose. Tightened it up, and the pressure holds great.

When I'm ready to get fuel in the lines, I'll probably attach some push lock fittings on the feed lines before the rails with hoses attached to the ends. I'd like to purge the system to get any crap out of the lines. I sprayed the lines with brake cleaner after every cut, but I'm sure there is still some debris left in them. I don't want to chance clogging up the injectors.

I mounted an additional fuel pump relay at the back of the car. This is in addition to the stock relay powered from the ECU. This additional relay will get me the 25A rating I need for the monster Fuelab pump.

Also mounted up the wastegate solenoids for the boost controller. I've decided to put the AMS-500 controller in the glove box. It' isn't something I'll need to access all the time, but the glove box is a good spot for when I need to get to it to make any changes. External switches will be mounted somewhere for the two stages of the controller.

I mocked up the dash to double check how long the wiring will need to be for the boost controller. I also wanted to get an idea of how much space I have to work with to fit the fuse box under there somewhere.

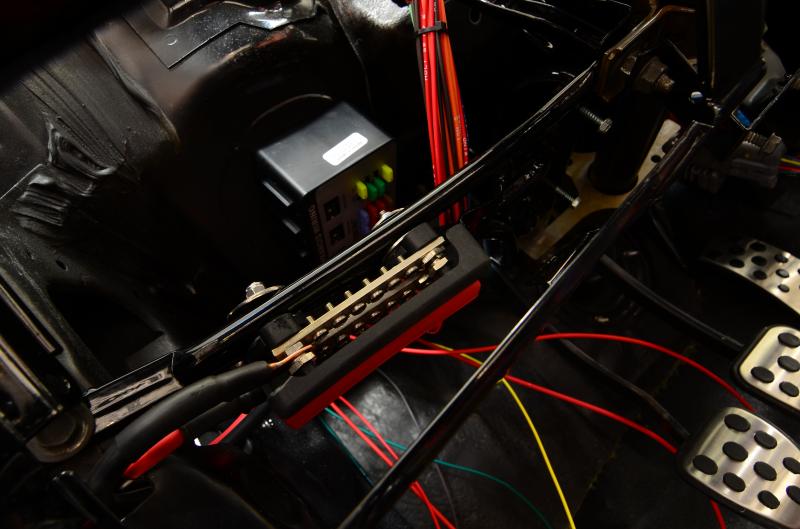

Speaking of fuse box. Here it is. The Ron Francis kit. This model has the option to use two 60# magnets to hold the fuse box to the chassis. This allows it to be 'mounted' up high in the dash. A firm tug on the box will release the magnets and it can be pulled down to the floor for easy access to fuses.

I decided to stick the box on the underside of the wiper cowl area. The magnets hold very well and I'll be able to leave enough slack in the wiring to drop it down to the floor as needed.

You can also see the hot and ground bus bars I have mounted under the fuse box. These will let me run taps out to any accessories inside the car without having to go into the fender to get to the 12V post. Makes life a little easier.

Here's a shot of car as she sits now during this whole wiring operation.

Time to start connecting all these wires, one wire at a time.

When I'm ready to get fuel in the lines, I'll probably attach some push lock fittings on the feed lines before the rails with hoses attached to the ends. I'd like to purge the system to get any crap out of the lines. I sprayed the lines with brake cleaner after every cut, but I'm sure there is still some debris left in them. I don't want to chance clogging up the injectors.

I mounted an additional fuel pump relay at the back of the car. This is in addition to the stock relay powered from the ECU. This additional relay will get me the 25A rating I need for the monster Fuelab pump.

Also mounted up the wastegate solenoids for the boost controller. I've decided to put the AMS-500 controller in the glove box. It' isn't something I'll need to access all the time, but the glove box is a good spot for when I need to get to it to make any changes. External switches will be mounted somewhere for the two stages of the controller.

I mocked up the dash to double check how long the wiring will need to be for the boost controller. I also wanted to get an idea of how much space I have to work with to fit the fuse box under there somewhere.

Speaking of fuse box. Here it is. The Ron Francis kit. This model has the option to use two 60# magnets to hold the fuse box to the chassis. This allows it to be 'mounted' up high in the dash. A firm tug on the box will release the magnets and it can be pulled down to the floor for easy access to fuses.

I decided to stick the box on the underside of the wiper cowl area. The magnets hold very well and I'll be able to leave enough slack in the wiring to drop it down to the floor as needed.

You can also see the hot and ground bus bars I have mounted under the fuse box. These will let me run taps out to any accessories inside the car without having to go into the fender to get to the 12V post. Makes life a little easier.

Here's a shot of car as she sits now during this whole wiring operation.

Time to start connecting all these wires, one wire at a time.

Last edited:

David Pepiton

Active Member

stangboy

Founding Member

I've been following this build since the beginning of the thread and all I can say is WOW! This build brings "TOP NOTCH" to a whole new level. I can only dream of building a car of this caliber. I don't think you can even pay a shop to do work this good. I'm not a fan of hatchbacks anymore but this car is my new "Dream Mustang". The attention to detail is mind-blowing. Maybe I've been sheltered all my life but I have NEVER seen a car built to this level of quality and detail. You need to win some kind of award for this car when you're finished @RacEoHolic330 .

Thanks a lot @stangboy. The kind words of encouragement make it all worth it and definitely help to keep me motivated. Just doing my darndest to build a car to the best of my ability.

@bird_dog0347, you can see the lift posts tucked behind the car in the last picture. I unbolted one of them and rolled it out of the way. I don't need the lift right now, and I wanted to be able to get my daily driver in the garage over the winter. Not really much of a need to get under the car for any of the wiring. It sits up high enough right now to get under it with my creeper and have plenty of room to work.

@bird_dog0347, you can see the lift posts tucked behind the car in the last picture. I unbolted one of them and rolled it out of the way. I don't need the lift right now, and I wanted to be able to get my daily driver in the garage over the winter. Not really much of a need to get under the car for any of the wiring. It sits up high enough right now to get under it with my creeper and have plenty of room to work.

Last edited:

So then,... what is the box that you have mounted in the rear seat area if that wasn't the fuse box?

#1.Pressurized fuel system check.

#2. Magnets to hold fuse panel.

Two more ideas I steal from you.

#1.Pressurized fuel system check.

#2. Magnets to hold fuse panel.

Two more ideas I steal from you.

That is a landing panel for the ECU wiring. It also houses the fuses for the computer, as opposed to using fuseable links like Ford originally used. Has nothing to do with the chassis wiring though. It's somewhat of an isolated system. It just needs battery power, ignition power, and ground. The landing panel makes troubleshooting any ECU problems very easy.

youve probably said it already and i just cant find it, but what ecu are you using?

ive been thinking on all this wiring stuff when i do mine, hopefully in a couple years, and i really dont look forward to the pita it looks like it is to get rid of the 20+ year old, underbuilt, problematic stock stuff. looks like you got a good handle on it though, i just hope for you that it all works when its done and you dont have to tear the whole thing back apart just because some stupid little thing didnt happen right (my luck, i'd get it all done and some connector would get uncrimped)

ive been thinking on all this wiring stuff when i do mine, hopefully in a couple years, and i really dont look forward to the pita it looks like it is to get rid of the 20+ year old, underbuilt, problematic stock stuff. looks like you got a good handle on it though, i just hope for you that it all works when its done and you dont have to tear the whole thing back apart just because some stupid little thing didnt happen right (my luck, i'd get it all done and some connector would get uncrimped)

Stock ECU with Anderson PMS.

It's a little intimidating when you are ripping out all the stock stuff. There are TONS of wires, but then you realize how much of it you won't need anymore. You won't believe how many wires there are for the 'dummy light' system. I'm also getting rid of things like the door chime module, anti-slosh module, in addition to some other things not needed. The power doors and windows will be the biggest pain to do. I need to merge some stock wiring with the aftermarket kit to make those work. If you have a good working knowledge of wiring, an EVTM, and patience, it's very doable. One wire at a time is the key. Get one thing working and then move onto the next. I'm also making up all of my own wiring diagrams. Just about all of my crimps are soldered in addition to being crimped, especially the larger cables. Everything is wrapped in heat shrink tubing. Luckily, the ECU wiring has absolutely no crimps with the exception of the MAF wiring. Everything else is a direct run from sensor to landing panel.

It's a little intimidating when you are ripping out all the stock stuff. There are TONS of wires, but then you realize how much of it you won't need anymore. You won't believe how many wires there are for the 'dummy light' system. I'm also getting rid of things like the door chime module, anti-slosh module, in addition to some other things not needed. The power doors and windows will be the biggest pain to do. I need to merge some stock wiring with the aftermarket kit to make those work. If you have a good working knowledge of wiring, an EVTM, and patience, it's very doable. One wire at a time is the key. Get one thing working and then move onto the next. I'm also making up all of my own wiring diagrams. Just about all of my crimps are soldered in addition to being crimped, especially the larger cables. Everything is wrapped in heat shrink tubing. Luckily, the ECU wiring has absolutely no crimps with the exception of the MAF wiring. Everything else is a direct run from sensor to landing panel.

are you just cutting off stock body connectors and re-using them, or does that kit come with a lot of em? i realize its not a pre-terminated thing, just kinda doing some window shopping and seeing what kind of headaches i'll be running into, and half the reason ive thought of doing this is that half the harness connectors in the car now have broken tabs.

The EFI kit came with all new pre-wired connectors for all the engine sensors. The chassis kit came with the connectors for the steering column, which includes the turn signal stalk connector. Any other connectors I need are coming from LRS or from NAPA. I won't be reusing any of the stock ones, as most of mine have broken tabs as well.

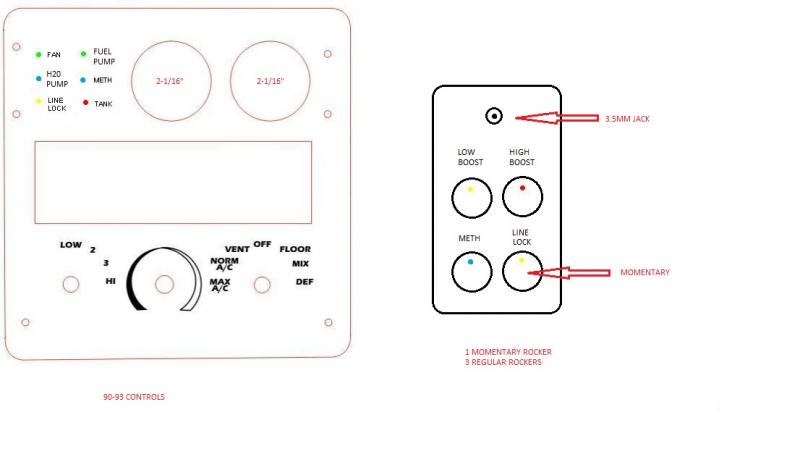

So, I'm getting ready to order some custom HVAC and ash tray plates from Gaugeplates.com. They make some really cool stuff over there. I proposed a layout, and I'm just curious what you guys think and how you would do things differently. Here's what I proposed...

The HVAC plate will have my 'dummy' lights on the left side, a PLX wideband in the middle, and a PLX boost gauge on the right. The cool thing about the boost gauge is that the gauge itself is a multi-gauge, so it will also display the oil pressure and I can toggle between the two displays. The head unit will be in the middle, and the HVAC controls on the bottom. For what it's worth, I'm doing Auto-meter gauges in the stock cluster with voltage, water temp, fuel pressure (electric), and fuel level.

The ash tray will have the two stages for the boost controller, the momentary switch for the line lock, and the on/off switch for the possible future methanol injection. There will also be a 3.5mm jack for the option of hooking up an ipod or phone to the stereo. I will probably never use it because I plan to get a head unit with SD card capability, but I figured it would be a good thing to have just incase.

Any suggestions on things to change or rearrange?

The HVAC plate will have my 'dummy' lights on the left side, a PLX wideband in the middle, and a PLX boost gauge on the right. The cool thing about the boost gauge is that the gauge itself is a multi-gauge, so it will also display the oil pressure and I can toggle between the two displays. The head unit will be in the middle, and the HVAC controls on the bottom. For what it's worth, I'm doing Auto-meter gauges in the stock cluster with voltage, water temp, fuel pressure (electric), and fuel level.

The ash tray will have the two stages for the boost controller, the momentary switch for the line lock, and the on/off switch for the possible future methanol injection. There will also be a 3.5mm jack for the option of hooking up an ipod or phone to the stereo. I will probably never use it because I plan to get a head unit with SD card capability, but I figured it would be a good thing to have just incase.

Any suggestions on things to change or rearrange?

Last edited:

I like that layout you've designedSo, I'm getting ready to order some custom HVAC and ash tray plates from Gaugeplates.com. They make some really cool stuff over there. I proposed a layout, and I'm just curious what you guys think and how you would do things differently. Here's what I proposed...

The HVAC plate will have my 'dummy' lights on the left side, a PLX wideband in the middle, and a PLX boost gauge on the right. The cool thing about the boost gauge is that the gauge itself is a multi-gauge, so it will also display the oil pressure and I can toggle between the two displays. The head unit will be in the middle, and the HVAC controls on the bottom. For what it's worth, I'm doing Auto-meter gauges in the stock cluster with voltage, water temp, fuel pressure (electric), and fuel level.

The ash tray will have the two stages for the boost controller, the momentary switch for the line lock, and the on/off switch for the possible future methanol injection. There will also be a 3.5mm jack for the option of hooking up an ipod or phone to the stereo. I will probably never use it because I plan to get a head unit with SD card capability, but I figured it would be a good thing to have just incase.

Any suggestions on things to change or rearrange?

How about a bulkhead connection for the PMS? This is assuming it uses a serial or other type interface.

I want to do something similar and I wanted to add a serial connection for the BS3 on the plate.

I want to do something similar and I wanted to add a serial connection for the BS3 on the plate.

That's a good idea. They do offer both serial and USB connectors. The PMS does connect via serial cable, but I may go with a USB and then use a serial-USB adapter for the handheld controller. I would be able to plug the laptop right into the USB. That can probably take the place of the audio jack. I'll just ask them to squeeze that in wherever it will fit, if possbible. It's not a must-have.

Similar threads

- Replies

- 32

- Views

- 40K

Progress Thread

'67 Mustang 351C > C4 trans > Clueless 21 year old

- Replies

- 5

- Views

- 2K

- Replies

- 3

- Views

- 10K

- Replies

- 1

- Views

- 7K

- Replies

- 2

- Views

- 3K