So guys I bought a cheap Frankenstein 89 carbed 5sp hatch with a little cam, flows and dumps. Car runs good overall and looks decent. Lots of little things that need to be done, but I wanted something to tinker with...

I thought that someone hacked up a belt system but finally realized that this setup comes out of a 80's LTD. Belt alignment is good, cooling is good, charging is bad (alternator is failing), but the belt squeals constantly at any rpm. If I dump the clutch between gears, it chirps and its quite annoying.

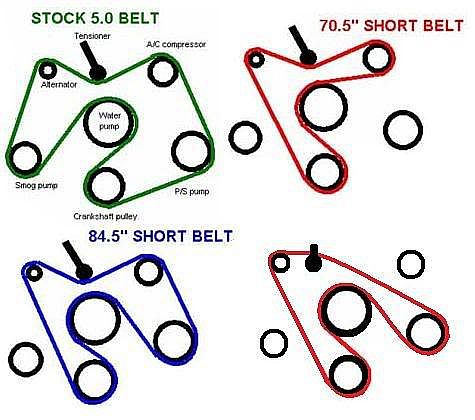

Here is an example of the setup (not mine) with the exception that I have a direct drive fan with a spacer (no clutch). The guy said that he just put a new belt and it still squeals.

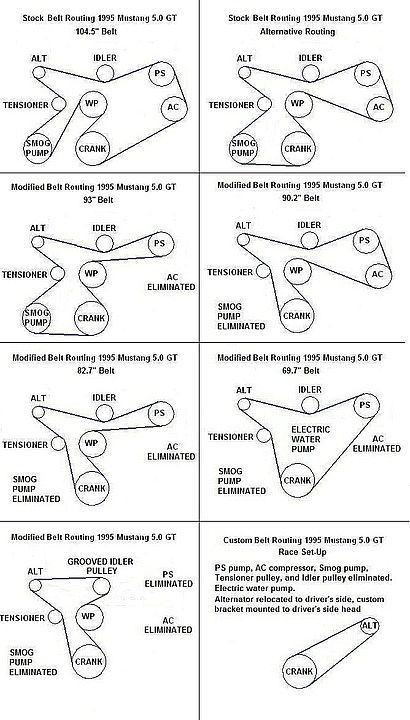

The crank pulley is huge and looks to overdrive the WP and the alternator quite a bit. I haven't bought a gatorback for the car yet, but any options? Anyone know of an old school trick to drive the WP slower and give more belt contact? A nice big WP pulley would most probably solve the issue. I may have to bite the bullet by going with an electric fan setup to reduce the load on the belt.

I thought that someone hacked up a belt system but finally realized that this setup comes out of a 80's LTD. Belt alignment is good, cooling is good, charging is bad (alternator is failing), but the belt squeals constantly at any rpm. If I dump the clutch between gears, it chirps and its quite annoying.

Here is an example of the setup (not mine) with the exception that I have a direct drive fan with a spacer (no clutch). The guy said that he just put a new belt and it still squeals.

The crank pulley is huge and looks to overdrive the WP and the alternator quite a bit. I haven't bought a gatorback for the car yet, but any options? Anyone know of an old school trick to drive the WP slower and give more belt contact? A nice big WP pulley would most probably solve the issue. I may have to bite the bullet by going with an electric fan setup to reduce the load on the belt.