Really? You think he's gonna change the existing structure out for "better tubing"? Have you seen the welds he's used to "tack" the mock up stuff? Looks pretty permanent to me.The 90 degree bends are tough without the right size dies and a bender like the jd2. I have seen guys bend tubing with a harbor freight bender but there are a few tricks to doing it without kinking the tubing. I remember a while back seeing a few videos on YouTube of guys getting the harbor freight bender to work. I'm not sure which type you have. What type of welder? 110 or 240 volts? I'm sure you have a grinder and I know harbor freight sells a tubing notcher for making the fish mouths pretty cheap, I used one for a long time and still have it somewhere, I have since upgraded though. I know aed motorsports ships all over the country but ill look to see tomorrow if I can find any place in Houston that has it. It will be much cheaper if you can pick it up somewhere.

The design you have looks to be good I like the bars the kick off the strut tower to the frame rail. Once we get you the right tubing you'll be in awesome shape!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Slow Boat To China

- Thread starter hoopty5.0

- Start date

-

Sponsors (?)

I don't know about you but I have a few grinders that would be up to the task, lolReally? You think he's gonna change the existing structure out for "better tubing"? Have you seen the welds he's used to "tack" the mock up stuff? Looks pretty permanent to me.

An unfortunate part of fabrication and especially when you first start is cutting stuff out when it's not quite right..

The 90 degree bends are tough without the right size dies and a bender like the jd2. I have seen guys bend tubing with a harbor freight bender but there are a few tricks to doing it without kinking the tubing. I remember a while back seeing a few videos on YouTube of guys getting the harbor freight bender to work. I'm not sure which type you have. What type of welder? 110 or 240 volts? I'm sure you have a grinder and I know harbor freight sells a tubing notcher for making the fish mouths pretty cheap, I used one for a long time and still have it somewhere, I have since upgraded though. I know aed motorsports ships all over the country but ill look to see tomorrow if I can find any place in Houston that has it. It will be much cheaper if you can pick it up somewhere. The design you have looks to be good I like the bars the kick off the strut tower to the frame rail. Once we get you the right tubing you'll be in awesome shape!

Found some tubing in Houston. There's .065, .095, and .120. Would the thicker wall be more inclined to bend on my HF bender? I have a 240v welder also.

I guess that all depends on your tubing bender. If you have one of those benders that uses a bottle jack and came w/ various dies as a whole unit, then you'll probably experience kinking as the mandrel will not be a tight enough tolerance wise to hold the bend tightly enough. The whole "What happens when you hit a wall at 100 MPH?" is a dumb argument anyway, as I'm pretty sure the stock stuff would wad up like chewing gum as well. I still scratch my head and wonder what you think you're gaining by doing this, citing "extra clearance benefits", especially since you intend to use a smallish LS engine under the hood in the first place. We all know there is enough room in the stock configuration to fit a 460 oinker in there, w/ room for 3 little pigs too.

I guess my new question is how are you intending to mock up mount points for the front sheet metal w/o stock reference points?

Not trying to gain anything really, other than "look what I did." I just enjoy building stuff, even though it may be the long way home.

As for the mounts, I'll cross that bridge as I come to it. I have an idea, but we'll see...

After this evening, I'd feel like an idiot for not re-doing it. I can't quite claim ignorance anymore...Really? You think he's gonna change the existing structure out for "better tubing"? Have you seen the welds he's used to "tack" the mock up stuff? Looks pretty permanent to me.

If its mild steel then I would certainly go .120 wall. Like I said look for a few YouTube videos on using that bender and not kinking the tubing. You will be amazed at how much more ridged it is. 240v welder is good. If you have a little propane/mapp gas torch just pre heat the metal before you weld it and you will find much better penetration than starting on it cold.

If you have a little propane/mapp gas torch just pre heat the metal before you weld it and you will find much better penetration than starting on it cold.

Never heard that before either. Learn something new every day.

gearheadboy

15 Year Member

I was simply stating a "what if?"Who said he's gonna hit the wall doing 100mph?

gearheadboy

15 Year Member

After looking at the pictures of other tube front ends I see they all look like they would smear should something out of the ordinary happen. Was simply making conversation including my opinion. Me with my dumb arguments. I'll refrain from here on in.I guess that all depends on your tubing bender. If you have one of those benders that uses a bottle jack and came w/ various dies as a whole unit, then you'll probably experience kinking as the mandrel will not be a tight enough tolerance wise to hold the bend tightly enough. The whole "What happens when you hit a wall at 100 MPH?" is a dumb argument anyway, as I'm pretty sure the stock stuff would wad up like chewing gum as well. I still scratch my head and wonder what you think you're gaining by doing this, citing "extra clearance benefits", especially since you intend to use a smallish LS engine under the hood in the first place. We all know there is enough room in the stock configuration to fit a 460 oinker in there, w/ room for 3 little pigs too.

I guess my new question is how are you intending to mock up mount points for the front sheet metal w/o stock reference points?

Going this morning to look at a complete 6.0l for a grand. Also going to stop by a metal place to see if they have the tubing I need...

Today was a pretty decent day.

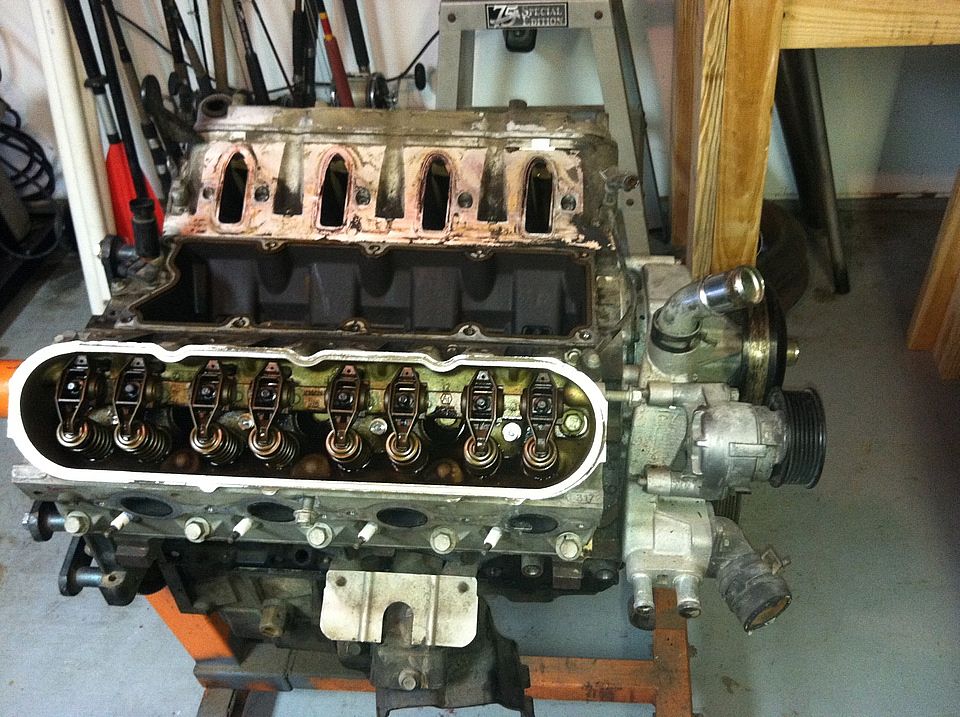

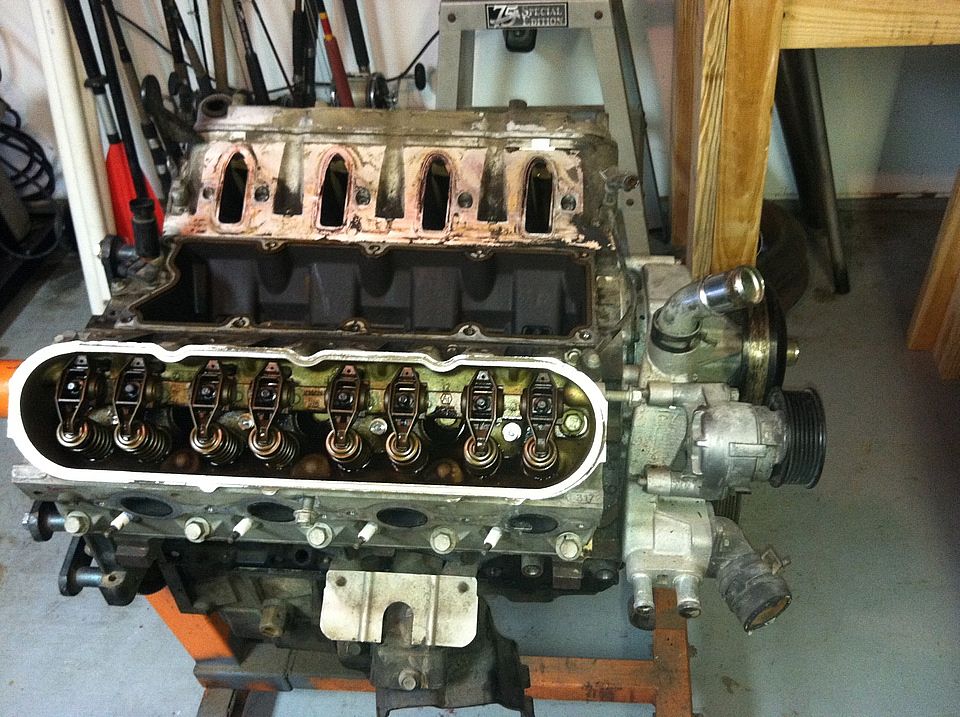

I got this:

It's a 2005 LQ4 - which is the lower compression (9.0:1) 6.0l LS motor. Scored it for a cool $950. It's clean on the inside too and the oil has good color.

From there, I went to a steel supplier in the 'hood of north Houston (almost got capped, seriously) and got some .095 1 1/2" mild steel DOM tubing ($$$$$$$$). Almost had to trade a kidney for it. 84Ttop

And was offered access to mandrel bender, so it should work out well.

Finally, after getting back home and taking the engine apart, the mail man delivered my struts, so I put the front end together so I could push the car out and clean my disgusting garage. I like to keep it raceoholic-type-clean so it's been eating at me slowly the past couple of weeks...

Finally, everything back to normal:

I got this:

It's a 2005 LQ4 - which is the lower compression (9.0:1) 6.0l LS motor. Scored it for a cool $950. It's clean on the inside too and the oil has good color.

From there, I went to a steel supplier in the 'hood of north Houston (almost got capped, seriously) and got some .095 1 1/2" mild steel DOM tubing ($$$$$$$$). Almost had to trade a kidney for it. 84Ttop

And was offered access to mandrel bender, so it should work out well.

Finally, after getting back home and taking the engine apart, the mail man delivered my struts, so I put the front end together so I could push the car out and clean my disgusting garage. I like to keep it raceoholic-type-clean so it's been eating at me slowly the past couple of weeks...

Finally, everything back to normal:

Attachments

Sharad

ALWAYS choose the V over the P!!! Wait... what?

Thanks guys.

The past few days have been spent at the office and putting a sprinkler system in my front yard. Might finish the teardown of the engine, but don't expect much from this thread for a while. Headed offshore next week. Gotta go make some monies $$$$...

The past few days have been spent at the office and putting a sprinkler system in my front yard. Might finish the teardown of the engine, but don't expect much from this thread for a while. Headed offshore next week. Gotta go make some monies $$$$...

Engine is now a short block. Could use some cam bearings and I'm sure te main bearings aren't too far behind. Gonna try and find a mild turbo cam now I guess...

Went to a swap meet this morning and scored a th400 from an rv for $100. I think my sub-10k budget is entirely feasible. 90% of the expensive stuff is bought already.

Also, this guy is running a stock bottom end with a cam and intake. Turbo is an s500

http://www.theturboforums.com/showthread.php?t=367847

Went to a swap meet this morning and scored a th400 from an rv for $100. I think my sub-10k budget is entirely feasible. 90% of the expensive stuff is bought already.

Also, this guy is running a stock bottom end with a cam and intake. Turbo is an s500

http://www.theturboforums.com/showthread.php?t=367847

I should also add I'm getting an ls6 intake for cheap and a wiring harness too for cheaper.

Remember the ARB issue I was having? Well it went down hill today. I narrowed the ARB 3.5" (With MUCH difficulty) to fit between the coil overs. The problem now is that the coil over crossmember is too far forward for the ARB to articulate up and down. I now have to cut out the crossmember, move it back a couple inches, and re-weld it up. After having a crap day with other issues, I left it alone. I'll deal with it later.

I've found that the race car world is as close to rocket science precision and accuracy as anything else. As this is my first real build, everything is having to be done and re-done, just like the front end of the car. Anything worth doing is worth doing right though. Going to make it Grade A so this thing doesnt crumble under the power.

The good news is the adapter to put a TH400 on the LSx is only $155.

I've found that the race car world is as close to rocket science precision and accuracy as anything else. As this is my first real build, everything is having to be done and re-done, just like the front end of the car. Anything worth doing is worth doing right though. Going to make it Grade A so this thing doesnt crumble under the power.

The good news is the adapter to put a TH400 on the LSx is only $155.

Love race cars yet? It gets easier the longer you do it, I promise. One thing about the crossmember/arb issue. The shocks must be plumb front to back and left to right which only leaves one spot for them to be. Moving the back may screw up the geometry of the shocks so check this carefully. As far as the arb goes you can trim the arm length equally on both sides, mount it above the floor with longer strut rods, or mount it on the rear end housing. You have a lot more options in mounting the arb than the shocks. Worse comes to it you can mount the shocks to tabs on the frame rail instead of the cross member. Also the anti roll bar tabs can be mounted on the front or back of the housing or if you mount the arb directly to the housing you can mount the tabs to the frame rail. Do look at it like rocket science, you are smarter than the metal!Remember the ARB issue I was having? Well it went down hill today. I narrowed the ARB 3.5" (With MUCH difficulty) to fit between the coil overs. The problem now is that the coil over crossmember is too far forward for the ARB to articulate up and down. I now have to cut out the crossmember, move it back a couple inches, and re-weld it up. After having a crap day with other issues, I left it alone. I'll deal with it later.

I've found that the race car world is as close to rocket science precision and accuracy as anything else. As this is my first real build, everything is having to be done and re-done, just like the front end of the car. Anything worth doing is worth doing right though. Going to make it Grade A so this thing doesnt crumble under the power.

The good news is the adapter to put a TH400 on the LSx is only $155.

Similar threads

Progress Thread

2004 Comp Orange GT

- Replies

- 9

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 23

- Views

- 3K

- Replies

- 0

- Views

- 1K