- Dec 19, 2010

- 5,719

- 4,238

- 224

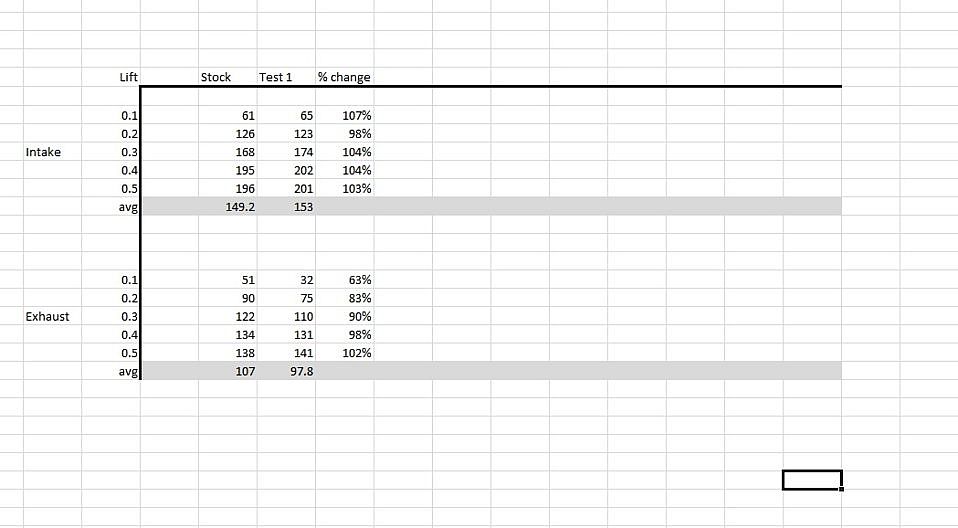

haha yeah, about 40 more hours of labor

*edit - not on that one runner, but my point is I have not spent any time on the intake runners yet to get a ton more flow. I have only done the most basic items which is why I am not expecting more.

Oh, I see.. So do you plan on spending that time, or just keeping it simple? Forgive me if you've mentioned it already and I overlooked it. Been busy busy..