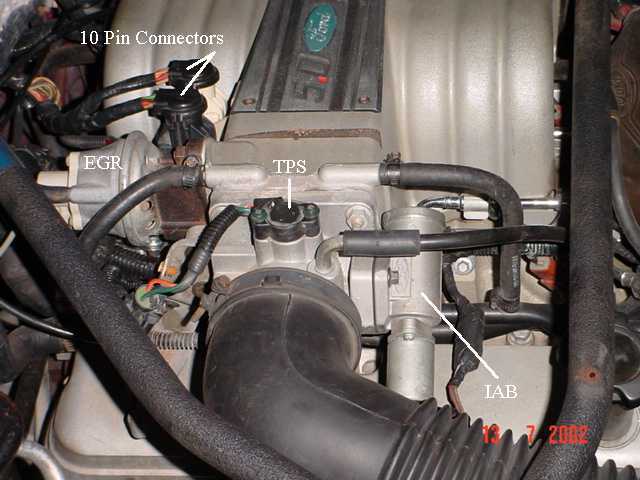

Here's the problem, the tps voltage was set at .98v, and it rises smoothly and normally to 4.8v at wot, all done with key on engine off. while the car is running though, voltage keeps jumping around, 1v, 3.6, 2.0, 6.5,5.0,1.9, etc.

I have already changed the tps to double check that, no change. Is the pcm the next thing? Its a whole new setup, the car ran great with a 302, no issues. now I have a 351w and a turbo. no change to the wiring harness, still an A9L computer. only mods to the electrical since the 302 was an external fuel pump.

The tuner has put a "base" program on a chip to start with. Unplugging the chip has no change. Any help would be great, trying to stick it on the dyno tomorrow.

I have already changed the tps to double check that, no change. Is the pcm the next thing? Its a whole new setup, the car ran great with a 302, no issues. now I have a 351w and a turbo. no change to the wiring harness, still an A9L computer. only mods to the electrical since the 302 was an external fuel pump.

The tuner has put a "base" program on a chip to start with. Unplugging the chip has no change. Any help would be great, trying to stick it on the dyno tomorrow.