This how-to will cover the installation of the MSD Launch Master (Part No. MSD-8734) on a 2007 Ford Mustang GT 5-Speed Manual.

Description from MSD:

Parts and Supplies Required:

MSD-8734

18 or 16 gauge primary wire

(2) crimp ring terminals

(1) magnetic reed switch

3/4" convoluted tubing (about 3 feet)

Electrical tape

Add a link fuseable link

wire zip ties

3M tape

Rocker switch and connectors (necessary for automatics only)

Epoxy suitable for metal and plastic

Tools Required:

Wire crimper

10mm socket or wrench

Phillips screw driver

Body pin puller (optional)

Drill and 1/4" drill bit

Notes:

Step 1:

Connect the 3-pin harness to the 2-step and connect the Black wire to the good engine or chassis ground. I used the existing body ground. Remove the bolt with a 10mm socket or wrench. Slide the ring terminal from the MSD harness on the bolt and re-install the bolt.

Step 2:

Disconnect the 2-pin connectors from each of the eight ignition coils. Each connector has a small tab that needs to be pushed in to release the clip.

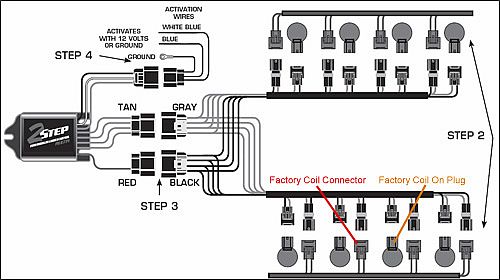

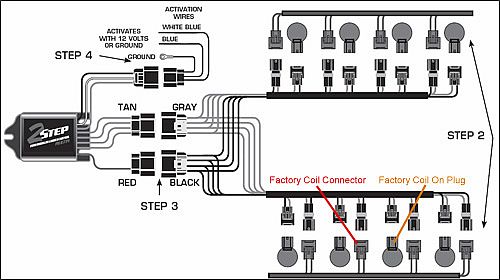

Step 3:

Connect all eight of the 2-pin male connectors from the MSD harness into the factory coil connectors. Only connect to the factory coil harness, and not the coils at this time.

Step 4:

Plug the 8-pin connector with the single Red wire from the 2-Step to the connector with Black wires.

Step 5:

Turn the key to the On position – do NOT start the engine. Look at the LED on the 2-Step:

Step 6:

Connect the 8-pin harness with the tan wires to the remaining connector on the harness. Once you've done this, go ahead and mount the unit. I held off on mounting to make sure the harness would reach and LED lit. You will need a drill to mount it, or optionally use 3M tape. If you use 3M tape, make sure you scuff the mounting surfaces well. I used a screw on the left, and 2 strips of 3M tape on the back.

Step 7:

Connect all eight of the female 2-pin connectors from the MSD harness into the factory coils. At this point, the connections to the coil on plugs are done. You can begin cleaning up the wiring now, or wait until you're done.

Step 8:

Choose whether you're going to use the ground activation wire or powered activation wire. Since I already had a switched wire run to the driver's side for my line locks, I tapped into that and went for the powered method. The powered activation wire is white with a blue stripe. The ground activation wire is blue. Clip the wire short that you do not intend on using. Otherwise, you'll just need to add an add-a-fuse link, which you'll see pictured below. I ran the activation wire through a hole below that battery and out into the wheel well. I pulled the passenger wheel off and pulled the rear fender liner out. I poked a hole through the large grommet and ran the wire in. Replace the fender liner and wheel.

Step 9:

Run the activation wire behind the center stack of the dash to the driver's side. Run another wire along with it, and connect one end to the add-a-fuse. Do not install the fuse yet, but leave enough slack so that you can install it. As always, make sure to zip tie up the wires when you're done to avoid a mess and make for a nice, clean, factory looking installation. At this point, we need to install a crimp ring terminal connector to each wire, and connect them to the magnetic switch. The white/blue wire needs to connect to the output side of the switch. The powered wire needs to connect to the closed circuit side of the switch.

(Note: The reed switch I used has a closed terminal and an open terminal. If you use the closed side, the unit will only activate when the switch is engaged. If you accidentally use the open side, the unit will be active all the time, and deactivate when the switch is engaged.) At this point, I plugged the fuse in and turned the car on. I had a helper watch the LED light on the MSD unit to make sure it came on when the magnet came close the the terminal piece of the switch. Once you confirm that the switch is working, disconnect the fuse and continue to the next step.

Step 10:

Mount both sides of the switch. You'll want to put the wired side on the firewall, and the magnetic side on the clutch pedal. I used a few spacers I had sitting around, along with a thin piece of plastic for a base. I used 3M tape to secure the spacers to the switch. I then epoxied the plastic base to the spacer and to the clutch pedal. I taped it all up and let it sit for an hour to cure. Of course, be sure to scuff any surfaces that will be taped or epoxied, and clean well for maximum adhesion. Again, connect the fuse, turn the car to On (do not start) and confirm the switch is working. If not, you may need to reposition the switch. Remember, the maximum distance for activation is about .65". Once you confirm the switch is working, move on to the next step.

Step 11:

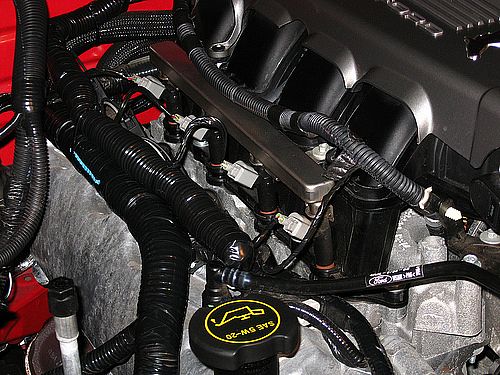

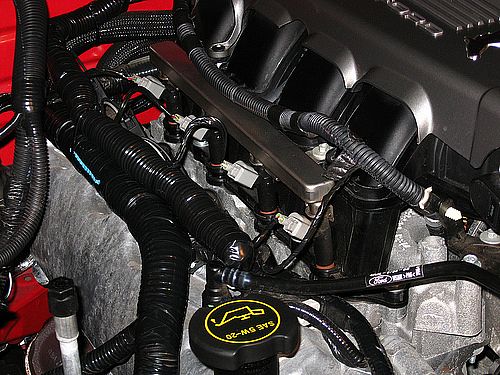

Clean up all wiring. I used some convoluted tubing and electrical tape in the engine bay, then zip tied it down to the existing tubing. Zip tie all wiring in the car, as well. Make sure that the wires are out of the way enough so that they don't interfere with the travel of the other pedals.

Step 12:

Test it out and enjoy! Use a low RPM first to ensure it's working properly. I chose 3000 RPMs. Also of note, the dial closest to the LED is for 1000's and the dial further from the LED is for 100's.

0=10,000 RPMs

1=11,000 RPMs

2=2,000 RPMs

3=3,000 RPMs

etc...

<embed src="http://videos.streetfire.net/vidiac.swf?video=c2aad1e6-2a6c-4ad7-89a1-9acf013da0ec" width="428" height="352" allowFullScreen="true" type="application/x-shockwave-flash" pluginspage="http://www.macromedia.com/go/getflashplayer"></embed><br/><a href="http://videos.streetfire.net/video/MSD-Launch-Master-2-Step_169789.htm?ref=007d7085-b6ac-4ae0-9d9b-9a7a013c92d1">MSD Launch Master 2 Step Test</a>

Trouble Shooting:

If the engine has trouble starting or running:

Description from MSD:

- Easily set a launch rpm for consistent holeshots

- Connects to the factory coils for easy installation

- The best way to launch hard

Parts and Supplies Required:

MSD-8734

18 or 16 gauge primary wire

(2) crimp ring terminals

(1) magnetic reed switch

3/4" convoluted tubing (about 3 feet)

Electrical tape

Add a link fuseable link

wire zip ties

3M tape

Rocker switch and connectors (necessary for automatics only)

Epoxy suitable for metal and plastic

Tools Required:

Wire crimper

10mm socket or wrench

Phillips screw driver

Body pin puller (optional)

Drill and 1/4" drill bit

Notes:

- For automatics, you will need to install a rocker switch on the activation wire, else the rev limiter will kick in any time you hit the brake. Of course, this is optional, but for safety, I do recommend it.

- A reed type switch is a magnetic switch that opens or closes a circuit when the magnets get in range of each other. In this case, the maximum distance for activation is approximately .65 inches. Keep this in mind when mounting your switch. I purchased my switch here.

- The unit can be mounted anywhere in your engine bay, just remember to have enough slack for all the wiring to reach, and that you can still access the adjustment dials.

- The RPMs must be a minimum of 1000 below the set limit before activation, or activation will not be allowed by the unit. (I.E. if you set the limiter at 3000 RPMs, you must be below 2000 for it to activate.)

Step 1:

Connect the 3-pin harness to the 2-step and connect the Black wire to the good engine or chassis ground. I used the existing body ground. Remove the bolt with a 10mm socket or wrench. Slide the ring terminal from the MSD harness on the bolt and re-install the bolt.

Step 2:

Disconnect the 2-pin connectors from each of the eight ignition coils. Each connector has a small tab that needs to be pushed in to release the clip.

Step 3:

Connect all eight of the 2-pin male connectors from the MSD harness into the factory coil connectors. Only connect to the factory coil harness, and not the coils at this time.

Step 4:

Plug the 8-pin connector with the single Red wire from the 2-Step to the connector with Black wires.

Step 5:

Turn the key to the On position – do NOT start the engine. Look at the LED on the 2-Step:

- LED On – This confirms that the wiring is correct and you can move to step 6.

- LED Off – The wiring is different for this application and needs to be changed. Turn the key Off, plug the 8-pin connector with the eight Gray wires into the connector with the single Red wire

Step 6:

Connect the 8-pin harness with the tan wires to the remaining connector on the harness. Once you've done this, go ahead and mount the unit. I held off on mounting to make sure the harness would reach and LED lit. You will need a drill to mount it, or optionally use 3M tape. If you use 3M tape, make sure you scuff the mounting surfaces well. I used a screw on the left, and 2 strips of 3M tape on the back.

Step 7:

Connect all eight of the female 2-pin connectors from the MSD harness into the factory coils. At this point, the connections to the coil on plugs are done. You can begin cleaning up the wiring now, or wait until you're done.

Step 8:

Choose whether you're going to use the ground activation wire or powered activation wire. Since I already had a switched wire run to the driver's side for my line locks, I tapped into that and went for the powered method. The powered activation wire is white with a blue stripe. The ground activation wire is blue. Clip the wire short that you do not intend on using. Otherwise, you'll just need to add an add-a-fuse link, which you'll see pictured below. I ran the activation wire through a hole below that battery and out into the wheel well. I pulled the passenger wheel off and pulled the rear fender liner out. I poked a hole through the large grommet and ran the wire in. Replace the fender liner and wheel.

Step 9:

Run the activation wire behind the center stack of the dash to the driver's side. Run another wire along with it, and connect one end to the add-a-fuse. Do not install the fuse yet, but leave enough slack so that you can install it. As always, make sure to zip tie up the wires when you're done to avoid a mess and make for a nice, clean, factory looking installation. At this point, we need to install a crimp ring terminal connector to each wire, and connect them to the magnetic switch. The white/blue wire needs to connect to the output side of the switch. The powered wire needs to connect to the closed circuit side of the switch.

(Note: The reed switch I used has a closed terminal and an open terminal. If you use the closed side, the unit will only activate when the switch is engaged. If you accidentally use the open side, the unit will be active all the time, and deactivate when the switch is engaged.) At this point, I plugged the fuse in and turned the car on. I had a helper watch the LED light on the MSD unit to make sure it came on when the magnet came close the the terminal piece of the switch. Once you confirm that the switch is working, disconnect the fuse and continue to the next step.

Step 10:

Mount both sides of the switch. You'll want to put the wired side on the firewall, and the magnetic side on the clutch pedal. I used a few spacers I had sitting around, along with a thin piece of plastic for a base. I used 3M tape to secure the spacers to the switch. I then epoxied the plastic base to the spacer and to the clutch pedal. I taped it all up and let it sit for an hour to cure. Of course, be sure to scuff any surfaces that will be taped or epoxied, and clean well for maximum adhesion. Again, connect the fuse, turn the car to On (do not start) and confirm the switch is working. If not, you may need to reposition the switch. Remember, the maximum distance for activation is about .65". Once you confirm the switch is working, move on to the next step.

Step 11:

Clean up all wiring. I used some convoluted tubing and electrical tape in the engine bay, then zip tied it down to the existing tubing. Zip tie all wiring in the car, as well. Make sure that the wires are out of the way enough so that they don't interfere with the travel of the other pedals.

Step 12:

Test it out and enjoy! Use a low RPM first to ensure it's working properly. I chose 3000 RPMs. Also of note, the dial closest to the LED is for 1000's and the dial further from the LED is for 100's.

0=10,000 RPMs

1=11,000 RPMs

2=2,000 RPMs

3=3,000 RPMs

etc...

<embed src="http://videos.streetfire.net/vidiac.swf?video=c2aad1e6-2a6c-4ad7-89a1-9acf013da0ec" width="428" height="352" allowFullScreen="true" type="application/x-shockwave-flash" pluginspage="http://www.macromedia.com/go/getflashplayer"></embed><br/><a href="http://videos.streetfire.net/video/MSD-Launch-Master-2-Step_169789.htm?ref=007d7085-b6ac-4ae0-9d9b-9a7a013c92d1">MSD Launch Master 2 Step Test</a>

Trouble Shooting:

If the engine has trouble starting or running:

- Check the switched 12V connection and the ground wire.

- Check all coil connections and connections to the factory coil harness.

- Try swapping the two 8 pin connectors, as outlined in Step 5.

The rev limiter does me no good if I'm still bogging.

The rev limiter does me no good if I'm still bogging. But hey... Looks like you have the 2 step dailed in. I didn't expect it to be as smooth holding the rpms as it is. Looks like that is going on my "Mod. Wishlist"

But hey... Looks like you have the 2 step dailed in. I didn't expect it to be as smooth holding the rpms as it is. Looks like that is going on my "Mod. Wishlist"