Thanks Rick. Btw, I assume you can get pricing for quicktime bellhousings. I may be needing one if I can't fit my DP between the car and my Lakewood. I hope it will work, but we will see.

I'm going to give Comp a try. Their ball bearing billet wheel turbos seem to make great power and people have had very good experiences with them. It's just taking a bit longer than I though it would for them to make the turbo and ship it out. It wasn't a big deal, but it is now delaying my progress. Oh well, it is what it is!

I'm going to give Comp a try. Their ball bearing billet wheel turbos seem to make great power and people have had very good experiences with them. It's just taking a bit longer than I though it would for them to make the turbo and ship it out. It wasn't a big deal, but it is now delaying my progress. Oh well, it is what it is!

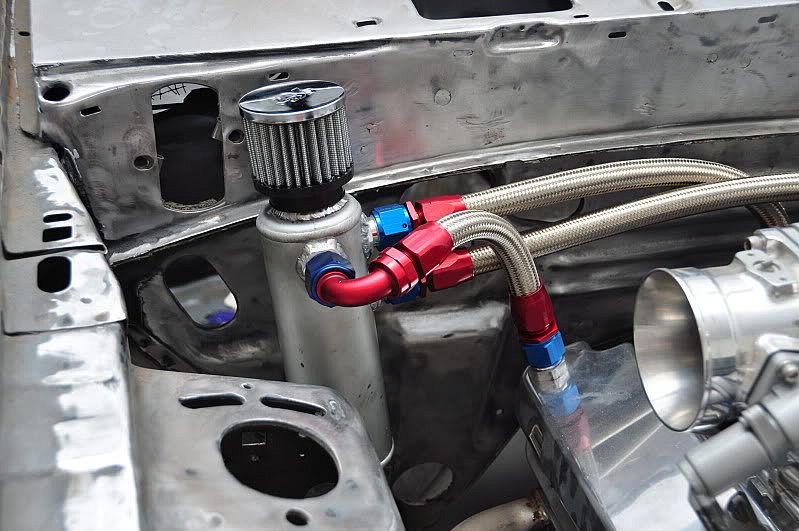

box together. FYI you can use the stock cap with this one as well.

box together. FYI you can use the stock cap with this one as well.