Damn, that is really thin. I didn't even know subwoofers came that thin. This one caught my eye:

http://www.crutchfield.com/p_130SWX251/Pioneer-TS-SWX251.html?tp=112

They're going for around $120 on ebay. Good reviews on Amazon too.

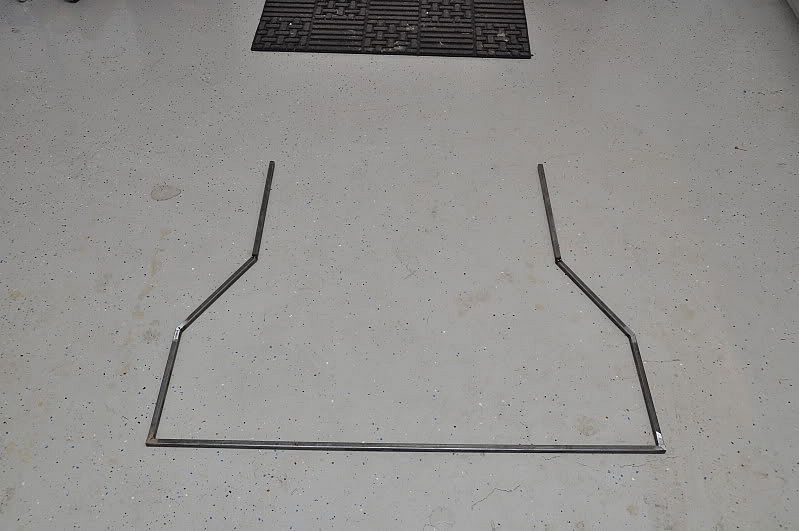

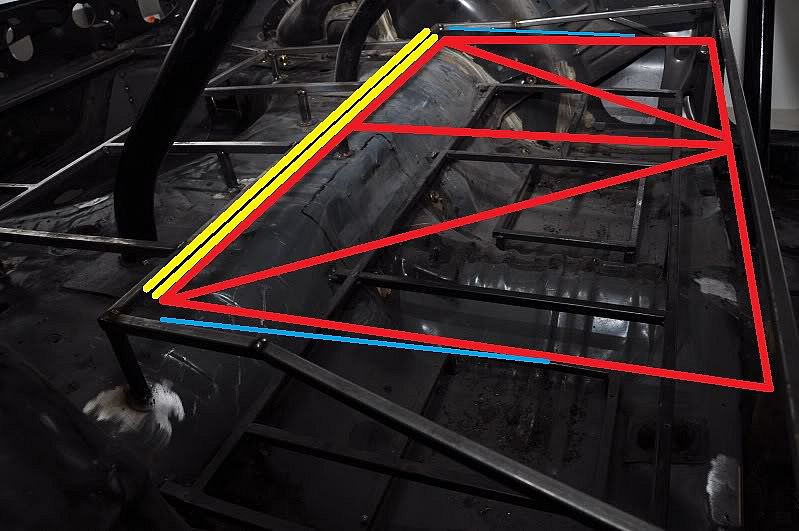

This thing is exactly the same thing, and can come in a loaded enclosure as well. I just figured that since you are trying to fit it into a round hole, the "square peg" might be a problem. I'd try my hand at building a custom box to fit the well instead.

Funny that you're moving the battery back, I just moved mine forward. All because the conventional sub/amp enclosure I have behind the seat will have to go when I start putting the rear mount A/C system back there. AND like you, I've become so accustomed to having the bass now, I don't want to lose it.

If I'd only waited until you started this build,.....The ideas I could've stole

If I'd only waited until you started this build,.....The ideas I could've stole

but read on to see you solved your own problem)

but read on to see you solved your own problem) . The guy at auto zone was at least nice enough to let me go to town pushing all their struts against the floor to see which ones would compress easily. They didn't have much to choose from, unfortunately.

. The guy at auto zone was at least nice enough to let me go to town pushing all their struts against the floor to see which ones would compress easily. They didn't have much to choose from, unfortunately.