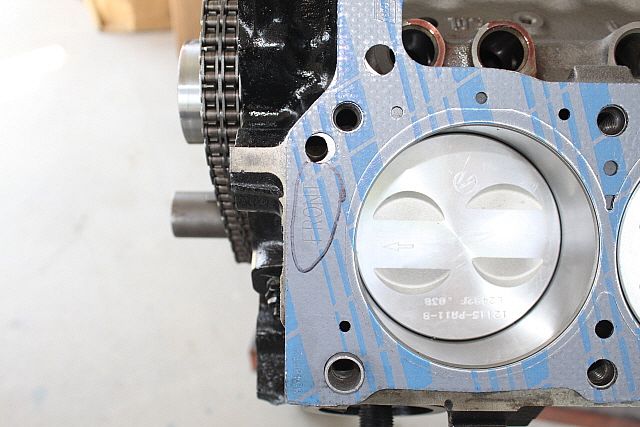

well it's going to be another one of those days i started to finnish the motor for the race car this morning and the oil pump suction tube mounting flange breaks off. i didn't even tighten the bolt on the outer edge of the flange and it falls off .its as brittle as a candy cane. this is a Melling pump ,never seen this happen before. i was threading the bolt in by hand and i heard somthing fall into the block ,it went all the way through ,i checked very well. the piece that came off is cracked in the middle also, almost as if it was hit on the corner or droped. it came off in one piece so nothing stayed in the motor .i am glad it did it now instead of later . could have been very expensive.

i started to finnish the motor for the race car this morning and the oil pump suction tube mounting flange breaks off. i didn't even tighten the bolt on the outer edge of the flange and it falls off .its as brittle as a candy cane. this is a Melling pump ,never seen this happen before. i was threading the bolt in by hand and i heard somthing fall into the block ,it went all the way through ,i checked very well. the piece that came off is cracked in the middle also, almost as if it was hit on the corner or droped. it came off in one piece so nothing stayed in the motor .i am glad it did it now instead of later . could have been very expensive.

i started to finnish the motor for the race car this morning and the oil pump suction tube mounting flange breaks off. i didn't even tighten the bolt on the outer edge of the flange and it falls off .its as brittle as a candy cane. this is a Melling pump ,never seen this happen before. i was threading the bolt in by hand and i heard somthing fall into the block ,it went all the way through ,i checked very well. the piece that came off is cracked in the middle also, almost as if it was hit on the corner or droped. it came off in one piece so nothing stayed in the motor .i am glad it did it now instead of later . could have been very expensive.

i started to finnish the motor for the race car this morning and the oil pump suction tube mounting flange breaks off. i didn't even tighten the bolt on the outer edge of the flange and it falls off .its as brittle as a candy cane. this is a Melling pump ,never seen this happen before. i was threading the bolt in by hand and i heard somthing fall into the block ,it went all the way through ,i checked very well. the piece that came off is cracked in the middle also, almost as if it was hit on the corner or droped. it came off in one piece so nothing stayed in the motor .i am glad it did it now instead of later . could have been very expensive.