- Feb 2, 2014

- 31

- 1

- 9

Hey guys heres another fun thread.

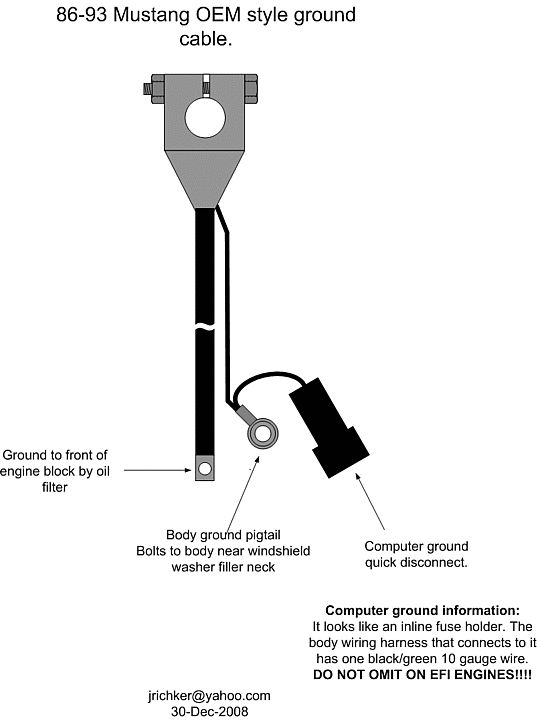

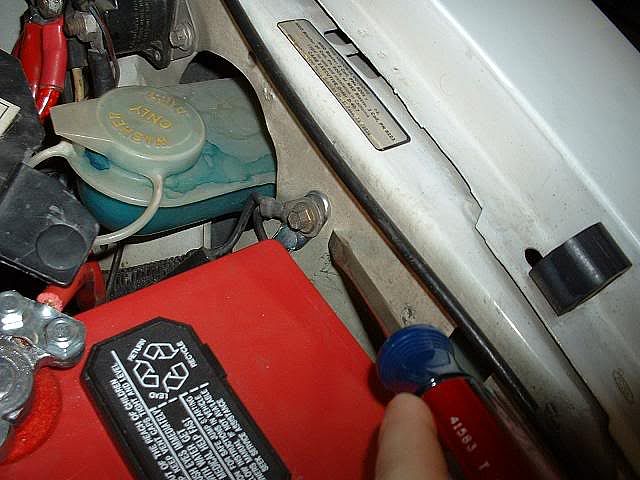

So as you all already know I currently own a 1988 mustang 5.0 lx. I bought the car back in november and I've had multiple issues. I currently have a misfiring issue so I was told to replace multiple things. I would get a misfiring/popping sound from my vehicle under a load and would feel like I am losing power until the car would catch up and speed up the misfiring ended. I replaced the fuel filter, sparkplugs (motorcraft gapped at .052), ignition wires (autolites), MSD Cap and rotor, MSD Ignition coil, Oil & filter change, Did a 3g alternator upgrade to a 130 amp alternator(kit bought from latemodelrestorations.com) with a bigger gauge wire that goes from the alternator to the ignition system, cleaned out the Iacv(looks brand new and had no carb build up in it at all so I believe that the previous owner knew about the issue), tested the TPS and it was at a .97 so it checked out good, I replaced the tfi ignition module(made no difference) so I was told I couldve been the pip sensor in the distributor. I just replaced the distributor about 2 weeks ago and when I did I made sure the #1 cylinder was top dead center and made sure the rotor was pointed toward the number 1 cylinder/sparkplug and installed the distributor. Then my neighbor(builds cars for atco raceway here in sj) used a timing light and set my timing to 12 degrees. After the new distributor (the brand is Tough One?) was installed I noticed that the car actually now bucks/jerks forward if i stay at a steady/constant speed. For example if I drive 25 mph for a while it'll buck/jerk forward a couple of times until I increase acceleration. Although this problem doesnt occur if I accelerate or am sitting at a light in neutral. After all of that work, the misfiring issue is still present, although it did seem to go away for a day or two after the distributor install. About a week ago I installed 6 new speakers and a new headunit correctly, and last night when I turned on my headlights, I noticed another problem now. The headlights were flickering and so was the lite up dashboard. The battery gauge on the dashboard itself was bouncing up and down as well(not giant bouncing but bouncing up and down as fast as the flickering). I've never had this issue before and it hasnt gone away since last night. It cant be the aftermarket headunit or speakers because this problem just began to happen and theyve been in for a week already. The negative and positive cables arent loose either so what could be the problem? The car still misfires/pops and bucks/ jerks forward at a constant speed and now I have this issue on top of it. I am really about to bash my head through a wall... I've only had the car almost 3 months now... and it didnt seem to have these issues the first few weeks i've had it... please help me...? :banghead:

Thanks guys..

So as you all already know I currently own a 1988 mustang 5.0 lx. I bought the car back in november and I've had multiple issues. I currently have a misfiring issue so I was told to replace multiple things. I would get a misfiring/popping sound from my vehicle under a load and would feel like I am losing power until the car would catch up and speed up the misfiring ended. I replaced the fuel filter, sparkplugs (motorcraft gapped at .052), ignition wires (autolites), MSD Cap and rotor, MSD Ignition coil, Oil & filter change, Did a 3g alternator upgrade to a 130 amp alternator(kit bought from latemodelrestorations.com) with a bigger gauge wire that goes from the alternator to the ignition system, cleaned out the Iacv(looks brand new and had no carb build up in it at all so I believe that the previous owner knew about the issue), tested the TPS and it was at a .97 so it checked out good, I replaced the tfi ignition module(made no difference) so I was told I couldve been the pip sensor in the distributor. I just replaced the distributor about 2 weeks ago and when I did I made sure the #1 cylinder was top dead center and made sure the rotor was pointed toward the number 1 cylinder/sparkplug and installed the distributor. Then my neighbor(builds cars for atco raceway here in sj) used a timing light and set my timing to 12 degrees. After the new distributor (the brand is Tough One?) was installed I noticed that the car actually now bucks/jerks forward if i stay at a steady/constant speed. For example if I drive 25 mph for a while it'll buck/jerk forward a couple of times until I increase acceleration. Although this problem doesnt occur if I accelerate or am sitting at a light in neutral. After all of that work, the misfiring issue is still present, although it did seem to go away for a day or two after the distributor install. About a week ago I installed 6 new speakers and a new headunit correctly, and last night when I turned on my headlights, I noticed another problem now. The headlights were flickering and so was the lite up dashboard. The battery gauge on the dashboard itself was bouncing up and down as well(not giant bouncing but bouncing up and down as fast as the flickering). I've never had this issue before and it hasnt gone away since last night. It cant be the aftermarket headunit or speakers because this problem just began to happen and theyve been in for a week already. The negative and positive cables arent loose either so what could be the problem? The car still misfires/pops and bucks/ jerks forward at a constant speed and now I have this issue on top of it. I am really about to bash my head through a wall... I've only had the car almost 3 months now... and it didnt seem to have these issues the first few weeks i've had it... please help me...? :banghead:

Thanks guys..