Proper plug gap for a 5.0 without NO2 or pressurized induction is .050.

Try spraying a fine mist of water around the plug wires with the engine running in the dark. Look for spark jumping or blue glow a round the wires.

If you are sure the spark plug wires are good, the ignition coil and TFI on the distributor are the other culprits in a high speed miss situation.

The TFI module mounted on the distributor is usually the culprit for a high speed miss on a warm engine. If the problem does not occur when the engine is cold, the TFI module is definitely suspect. You may need a special socket to remove the TFI module, but most auto parts stores will have one for $5-$7.

Be sure to use plenty of the heat sink grease on the new TFI and clean the old grease off the distributor.

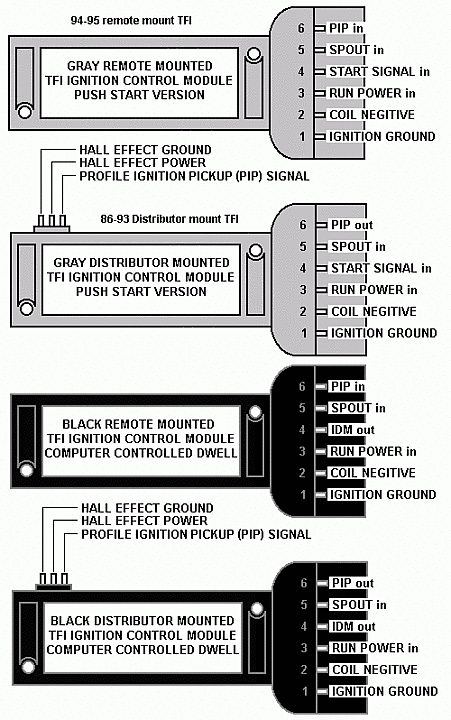

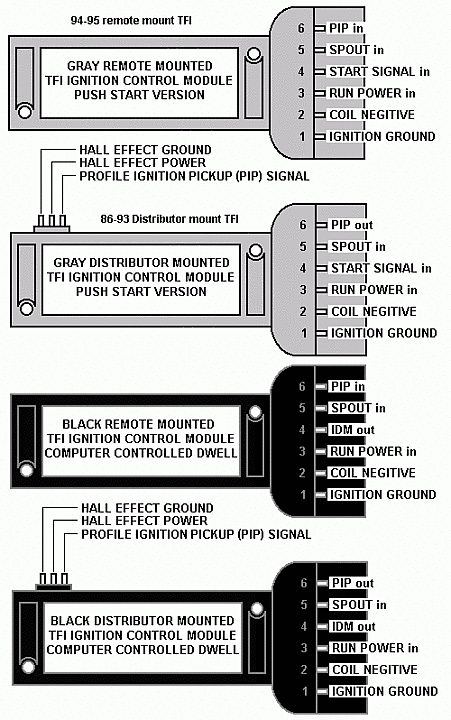

View attachment 113973

See Automotive Tools Specialty | Auto Mechanic & Technician Diagnostic, Testing Equipment | Thexton

diagram courtesy of Tmoss & Stang&2Birds

Try spraying a fine mist of water around the plug wires with the engine running in the dark. Look for spark jumping or blue glow a round the wires.

If you are sure the spark plug wires are good, the ignition coil and TFI on the distributor are the other culprits in a high speed miss situation.

The TFI module mounted on the distributor is usually the culprit for a high speed miss on a warm engine. If the problem does not occur when the engine is cold, the TFI module is definitely suspect. You may need a special socket to remove the TFI module, but most auto parts stores will have one for $5-$7.

Be sure to use plenty of the heat sink grease on the new TFI and clean the old grease off the distributor.

View attachment 113973

See Automotive Tools Specialty | Auto Mechanic & Technician Diagnostic, Testing Equipment | Thexton

diagram courtesy of Tmoss & Stang&2Birds