Thanks to jrichker on my last post I've been able to rule out my code 22 to bad wiring and my code 66 turned out to be a memory code from when I started the car without the cold air tube on. Now however the shuddering is back and a lot worse. I have ruled it out to be an issue with the tps sensor thanks to code 63. However when I check the tps voltage it seems to be normal at .88 volts with key on engine off. This is where I've had it since i got my new tps only around a month ago which fixed my violent shuddering previously. My guess is that the white 10 pin connector is causing me issues as the problem is intermittent and I'm wondering if theres any tests I can do to check the vref of the tps while wiggling the 10 pin to see if it'll lose connection? If so how would I go about doing this? Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Code 63 and more shuddering

- Thread starter sav22rem22

- Start date

-

Sponsors (?)

Code 63 - Throttle Position Sensor (TPS) signal too low.Thanks to jrichker on my last post I've been able to rule out my code 22 to bad wiring and my code 66 turned out to be a memory code from when I started the car without the cold air tube on. Now however the shuddering is back and a lot worse. I have ruled it out to be an issue with the tps sensor thanks to code 63. However when I check the tps voltage it seems to be normal at .88 volts with key on engine off. This is where I've had it since i got my new tps only around a month ago which fixed my violent shuddering previously. My guess is that the white 10 pin connector is causing me issues as the problem is intermittent and I'm wondering if theres any tests I can do to check the vref of the tps while wiggling the 10 pin to see if it'll lose connection? If so how would I go about doing this? Thanks

Revised 02-Jul-2009 to update TPS setting procedure & add 10 pin connector layout.

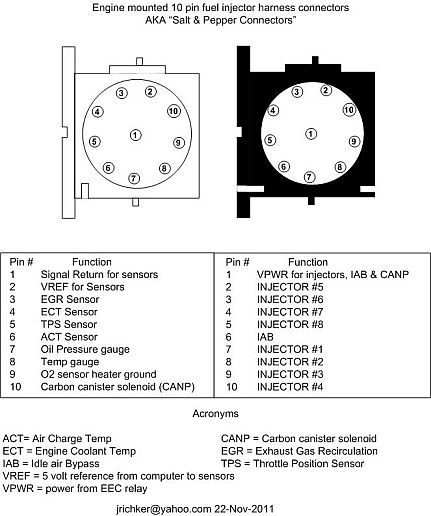

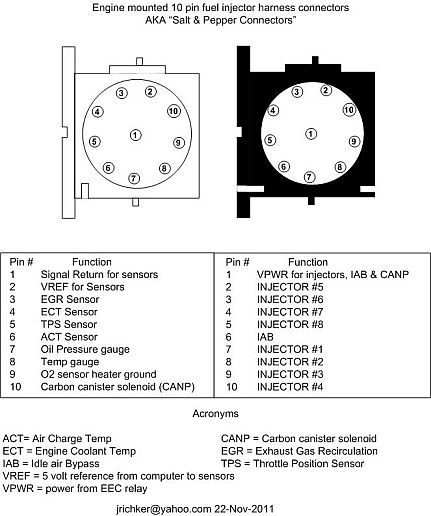

Vref missing (5 volt reference voltage supplied by the computer), bad connections or damaged wiring, TPS sensor failed, TPS sensor way out of adjustment. Use a DVM to check for 5 volts on the Orange wire. If it is missing, look for +5 volts at the Orange wire on the EGR or MAP/Baro sensor located on the firewall near the center of the car. If there is +5 volts on the MAP/Baro sensor, but not on the EGR, clean the #2 & #5 pin on the white 10 pin connector. If there is +5 volts on the EGR but not on the TPS, look for bad wiring inside the engine fuel injector harness.

See the graphic for the 10 pin connector circuit layout.

Setting the TPS voltage

You'll need a Digital Voltmeter (DVM) to do the job.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

Always use the Dark Green/lt green & Black/white wires to set the TPS base voltage.

Do the test with the ignition switch in the Run position without the engine running.

Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

Setting the TPS: you'll need a good Digital Voltmeter (DVM) to do the job. Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy.

Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems.

The Orange/White wire is the VREF 5 volts from the computer. You use the Dark Green/Lt green wire (TPS signal) and the Black/White wire (TPS ground) to set the TPS. Use a pair of safety pins to probe the TPS connector from the rear of the connector. You may find it a little difficult to make a good connection, but keep trying. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running.

Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

The TPS is a variable resistor, much like the volume control knob on a cheap radio. We have all heard them crackle and pop when the volume is adjusted. The TPS sensor has the same problem: wear on the resistor element makes places that create electrical noise. This electrical noise confuses the computer, because it expects to see a smooth increase or decrease as the throttle is opened or closed.

TPS testing: most of the time a failed TPS will set code 23 or 63, but not always. Use either an analog meter or a DVM with an analog bar graph and connect the leads as instructed above. Turn the ignition switch to the Run position, but do not start the engine. Note the voltage with the throttle closed. Slowly open the throttle and watch the voltage increase smoothly, slowly close the throttle and watch the voltage decrease smoothly. If the voltage jumps around and isn’t smooth, the TPS has some worn places in the resistor element. When the throttle is closed, make sure that the voltage is the same as what it was when you started. If it varies more than 10%, the TPS is suspect of being worn in the idle range of its travel.

Thanks jrichker. I’ve confirmed that I do have my 5 volts reference on the tps and I haven’t checked the bap or egr yet. I have noticed that my tps voltage is normal with the car off but when I start the car up the tps voltage spikes all over the place and that’s probing the green and black wire as if I were setting my tps. Any idea what could cause the jumping like that as I’m pretty sure that’s what is causing my code 63 and shuddering?Code 63 - Throttle Position Sensor (TPS) signal too low.

Revised 02-Jul-2009 to update TPS setting procedure & add 10 pin connector layout.

Vref missing (5 volt reference voltage supplied by the computer), bad connections or damaged wiring, TPS sensor failed, TPS sensor way out of adjustment. Use a DVM to check for 5 volts on the Orange wire. If it is missing, look for +5 volts at the Orange wire on the EGR or MAP/Baro sensor located on the firewall near the center of the car. If there is +5 volts on the MAP/Baro sensor, but not on the EGR, clean the #2 & #5 pin on the white 10 pin connector. If there is +5 volts on the EGR but not on the TPS, look for bad wiring inside the engine fuel injector harness.

See the graphic for the 10 pin connector circuit layout.

Setting the TPS voltage

You'll need a Digital Voltmeter (DVM) to do the job.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

Always use the Dark Green/lt green & Black/white wires to set the TPS base voltage.

Do the test with the ignition switch in the Run position without the engine running.

Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

Setting the TPS: you'll need a good Digital Voltmeter (DVM) to do the job. Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy.

Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems.

The Orange/White wire is the VREF 5 volts from the computer. You use the Dark Green/Lt green wire (TPS signal) and the Black/White wire (TPS ground) to set the TPS. Use a pair of safety pins to probe the TPS connector from the rear of the connector. You may find it a little difficult to make a good connection, but keep trying. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running.

Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

The TPS is a variable resistor, much like the volume control knob on a cheap radio. We have all heard them crackle and pop when the volume is adjusted. The TPS sensor has the same problem: wear on the resistor element makes places that create electrical noise. This electrical noise confuses the computer, because it expects to see a smooth increase or decrease as the throttle is opened or closed.

TPS testing: most of the time a failed TPS will set code 23 or 63, but not always. Use either an analog meter or a DVM with an analog bar graph and connect the leads as instructed above. Turn the ignition switch to the Run position, but do not start the engine. Note the voltage with the throttle closed. Slowly open the throttle and watch the voltage increase smoothly, slowly close the throttle and watch the voltage decrease smoothly. If the voltage jumps around and isn’t smooth, the TPS has some worn places in the resistor element. When the throttle is closed, make sure that the voltage is the same as what it was when you started. If it varies more than 10%, the TPS is suspect of being worn in the idle range of its travel.

Update: So as I've been messing with the 10 pins a little more I've noticed that the VPWR wire on top and bottom of the black 10 pin has been cut and hard wired with a wire nut. I've also been able to mess with the 10 pins and make the cars idle change and now my temp gauge actually reads in the middle like its supposed to however the shuddering is now intermittent rather than always the there. I also verified that my bap and EGR are getting 5 volts VREF so I honestly believe this is a problem with the 10 pins and in the wiring somehwere.

Keep on looking, you are on the right track.

for more 10 Pin connector help, see

or Google mustang 5.0 10 pin connector...

for more 10 Pin connector help, see

or Google mustang 5.0 10 pin connector...

Thanks jrichker. I have sourced a new used computer and injector harness and should have it in by next week. My current one has been hacked up to death already by the previous owners so I’ve decided it’s time for a better condition oneKeep on looking, you are on the right track.

for more 10 Pin connector help, see

or Google mustang 5.0 10 pin connector...

Another update: New harness is in (not done by me) and he removed some more smog stuff (all of the solenoids and what not on the passenger strut tower) so I have more codes that I’m not too worried about but so far the sputtering has completely gone away however code 22 is still here even with a new working harness and a new used working bap sensor. The car idles a whole lot better as well. If I start shuddering again I’ll probably just de pin the 10 pins and hardwire them to completely remove them from the equation

91GTstroked

15 Year Member

- Jun 14, 2007

- 429

- 236

- 63

Great information. I have a used injector harness I'll be installing. I found my current one has some injector wires pretty kinked and open wires exposed.

Removing the solenoids etc is just going to irritate the "new" computer and have no full pedal increase in power, short of what it takes to spin the air pump, and that should not be much. In my car, missing and hacked emissions ""junk" was causing a nasty rich mixture and a boatload of codes when I bought it.Another update: New harness is in (not done by me) and he removed some more smog stuff (all of the solenoids and what not on the passenger strut tower) so I have more codes that I’m not too worried about but so far the sputtering has completely gone away however code 22 is still here even with a new working harness and a new used working bap sensor. The car idles a whole lot better as well. If I start shuddering again I’ll probably just de pin the 10 pins and hardwire them to completely remove them from the equation

If that's the kind of hack work or low understanding of EECIV you paid for, you paid too much and did not get America's Best.

Now, I like 21.5 mph plus with E10 on the interstate. I like getting codes 11 after replacing or repairing the smog stuff, and I like how it did not slow my car down, at least that I can tell on the street. And I do not mind keeping the air cleaner for my family, the cows, the wild turkeys and cranes. (Snakes and spiders can choke on my exhaust and tire smoke.)

If you live where the ECU can be reprogrammed to run efficiently without the absent parts, that would be the next best deal for driveability.

Last edited:

That is ugly and obviously a potential issue. I bought a set of new injector pigtails (I have seen them at our sponsors' sites and on fleabay) to replace as the brittle connesctors that loose the clips. Soldering two good splice and two layers of heat shrink will be as good as new. It is easier than installing another used harness, and is cheaper than a new one I do not need now.

Great information. I have a used injector harness I'll be installing. I found my current one has some injector wires pretty kinked and open wires exposed.

91GTstroked

15 Year Member

- Jun 14, 2007

- 429

- 236

- 63

That is ugly and obviously a potential issue. I bought a set of new injector pigtails (I have seen them at our sponsors' sites and on fleabay) to replace as the brittle connesctors that loose the clips. Soldering two good splice and two layers of heat shrink will be as good as new. It is easier than installing another used harness, and is cheaper than a new one I do not need now.

Yeah, I can't get to that bad injector connector without removing the upper intake. I checked all wires on my spare harness, and put new wire tubing on it. I also cleaned all connections.

Probably just swap it out.

Similar threads

- Replies

- 0

- Views

- 299

- Replies

- 151

- Views

- 11K

- Replies

- 10

- Views

- 2K

- Replies

- 4

- Views

- 1K

- Replies

- 5

- Views

- 1K