I checked all the ground wires I could find and all were good...even cleaned up each and reattached...no resistance between grounds and negative battery cable. I started with Code 22 which should be the MAP/BAP sensor. In checking my connector, the wires I have are Black/White, Light Green/Black and Gray/Red. I'm assuming that the Gray/Red may actually be my Orange/White. Anyway, I checked resistance between the Black/White and the negative battery cable and came up with a repeatable 287 ohms. Sounds like I may have a ground issue as you suggested. I assume my next step is to turn on the ignition and check voltage between the Gray/Red (Orange/White) and Black/White, looking for 5 volts? I do not have an oscilloscope, but it looks like I may be heading toward the source of my problem with a digital VOM. Just thinking, can I simply add a jumper wire and ground the Black/White wire to the car to make a successful ground?

No...

Here's why....

Why do the engine control sensors have a separate ground?

The computer pin 46 signal ground is a critical component: it provides a signal ground for the Map/Baro, TPS, ECT, EGR position and ACT sensors. Every sensor has to have a reliable ground for it to provide accurate and useful information to the engine control computer.

The more current that flows through a conductor, whether it is a cable or the car body, the greater the voltage drop. The ground on the car body and ground cable for the engine block may have different voltage drops. Some of the voltage drops change depending on electrical loads such as lights, A/C, and heater blower settings.

Under high current loads, there can be large changes in the voltage drop across the ground wiring that goes back to the negative battery cable. If the engine sensors ground is combined with power ground, the computer will see these changes in the ground as a change in sensor input. This voltage change is very undesirable for reliable computer operation, so the engine sensors all have a separate shared ground.

The engine mounted sensors all have outputs of 5 volts or less. Therefore, any small changes in voltage seen by the computer analog signal inputs can have a large effect in engine performance. Signal ground is used in many circuits that have analog inputs to eliminate the voltage drop across the engine block and body grounds when current flows through them. There is very little current flowing through the signal ground and the voltage drop across the signal ground is so small that it can be ignored by the computer.

The voltage output of any sensor must always use the signal ground for the sensor under test in order to eliminate any errors or variances. That way, what the voltmeter sees is what the computer sees unless there is a problem with the sensor wiring.

Here's a repeat of the testing process for signal ground problems in case you missed something....

The 91 and later Mustangs will have a different color signal ground wire in the body side of the circuit . The wire colors for the engine mounted fuel injector harness are the same.. See the diagrams below for more help

Disconnect the positive battery cable to insure correct results when measuring the resistance of grounds. The small voltage drop that is often in a circuit can cause erroneous readings. Since the computer and several other things still draw current even with the ignition switch in the Off position, this is a necessary step.

Check the black/white wire resistance. Connect one ohmmeter lead to the black/white wire on the TPS and one lead to the negative post on the battery. You should see less than 1.5 Ω; more than that indicates a problem. Always take resistance measurements with the circuit powered off.

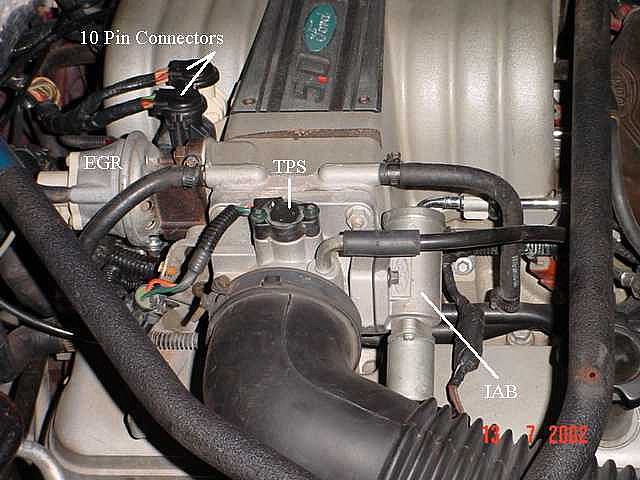

Check the resistance of the black/white signal ground on the MAP/BARO sensor on the firewall behind the upper intake manifold. The resistance should be less than 1.5 Ω If the resistance value of the black/white signal ground on the MAP/BARO is1.5 Ω and the TPS is higher or doesn't read at all, then there is a problem in the engine mounted fuel injection harness or the 10 pin connector

Clean the 10 pin salt & pepper shaker connectors.

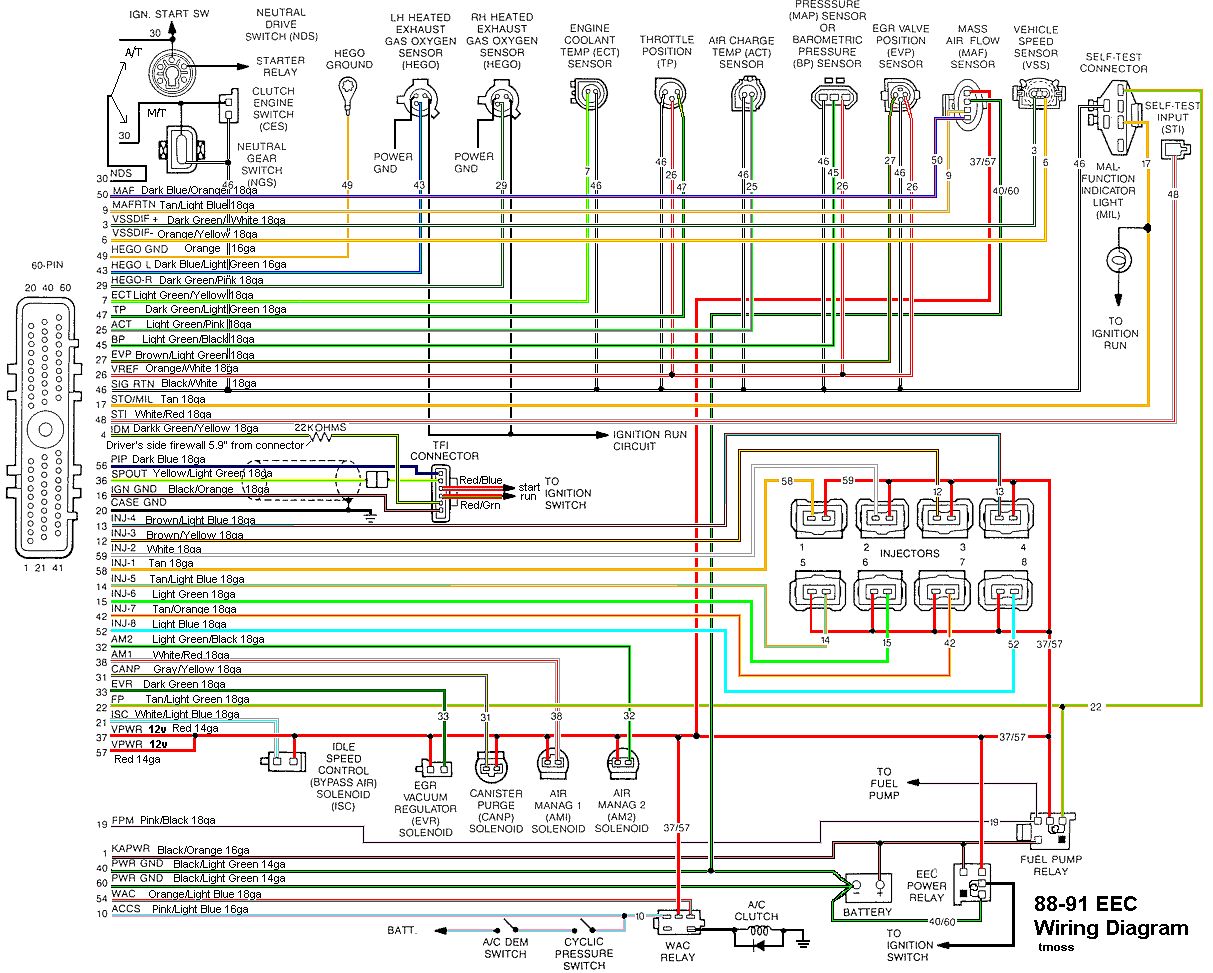

Diagram courtesy of Tmoss & Stang&2birds

See the graphic for the 10 pin connector circuit layout.

The injector power pin is the VPWR pin in the black 10 pin connector. [/b]

How it is supposed to work:

The black/white wire (computer pin 46) is signal ground for the computer. It provides a dedicated ground for the EGR, Baro, ACT, ECT, & TPS sensors as well as the ground to put the computer into self test mode. Since it is a dedicated ground, it passes through the computer on its way to the computer main power ground that terminates at the battery pigtail ground. It should read less than 1.5 Ω when measured from anyplace on the engine harness with the battery pigtail ground as the other reference point for the ohmmeter probe. What sometimes happens is that it gets jumpered to power which either burns up the wiring or burns the trace off the pc board inside the computer. That trace connects pins 46 to pins 40 & 60, which are power ground for the computer.

See the pictures below for help finding and fixing the burnt computer trace.

The fix is some careful soldering of a small jumper wire across the burnt section of copper trace.

How to test the wiring:

Disconnect the positive battery cable to insure correct results when measuring the resistance of grounds. The small voltage drop that often in a circuit can cause erroneous readings. Since the computer and several other things still draw current even with the ignition switch in the Off position, this is a necessary step.

With the power off, measure the resistance between the computer test ground (black/white wire) on the self-test connector and battery ground. You should see less than 1.5 Ω

If that check fails, remove the passenger side kick panel and disconnect the computer connector. There is a 10 MM bolt that holds it in place. Measure the resistance between the black/white wire and pin 46: it should be less than 1.5 ohms. More than 1.5 ohms is a wiring problem. If it reads 1.5 ohms or less, then the computer is suspect. On the computer, measure the resistance between pin 46 and pins 40 & 60: it should be less than 1.5 ohms. More than that and the computer’s internal ground has failed, and the computer needs to be repaired or replaced.

Measure the resistance between the black/white wire on each of the following sensors: TPS, ECT, ACT and EGR. If you find one that is greater than 1.5 Ω, measure between that sensor and pin #1 of the white 10 pin connectors. Pin #1 is the center pin and is labeled sig-rtrn on the diagram

The 91 and later Mustangs will have a different color signal ground wire in the body side of the circuit . The wire colors for the engine mounted fuel injector harness are the same..

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

I have done a little more checking this evening. I tested for resistance between the Black/White and the negative battery terminal on the BAP, TPS and EGR...and coincidentally, all are 287 ohms. I did an ignition on voltage check from the Black/White to the Gray/Red (Orange/White) and instead of 5volts, I got -460mv? Not sure how that's possible, but that's what my VOM read for each of the three locations. Seems like a number of posters are mentioning the O2 sensors. When I received the T-5 conversion kit from NEO Mustangs, it had a new harness that connected right up to my existing O2 sensors. Others are talking about jumpering leads. any thoughts on next steps...other than popping out the CEL? One other thought is that after the trans. swap, my idle was a little on the low side such that if you quickly let off the accelerator at idle while parking, it has a tendency to stall. I greatly appreciate your help to-date. Seems like I'm finding problems, but not sure of a cure...

I have done a little more checking this evening. I tested for resistance between the Black/White and the negative battery terminal on the BAP, TPS and EGR...and coincidentally, all are 287 ohms. I did an ignition on voltage check from the Black/White to the Gray/Red (Orange/White) and instead of 5volts, I got -460mv? Not sure how that's possible, but that's what my VOM read for each of the three locations. Seems like a number of posters are mentioning the O2 sensors. When I received the T-5 conversion kit from NEO Mustangs, it had a new harness that connected right up to my existing O2 sensors. Others are talking about jumpering leads. any thoughts on next steps...other than popping out the CEL? One other thought is that after the trans. swap, my idle was a little on the low side such that if you quickly let off the accelerator at idle while parking, it has a tendency to stall. I greatly appreciate your help to-date. Seems like I'm finding problems, but not sure of a cure...