The crown vic harness is the same as the ho engine just checked and pins are all in the right places my current problem is that it will start and run but won't rev past 2500 rpms or idle for long and when the iac is plugged in it dies the guy I bought the pcm from says the pcm was th fault new fault codes are 23 and 95

Do an end to end injector wring test to make sure that the injectors are properly sequenced for a HO engine and computer.

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8

HO wiring end to end continuity check. This will verify that the computer and engine wiring harnesses are correctly wired for a HO fuel injector wiring scheme.

Disconnect the main connector from the computer and pull it down so that you have good access to the computer side of the connector.

Place one voltmeter lead in pin 40 or 60 - they are both the main computer power ground. This lead does not change for any of the tests

Disconnect

all the injector connectors from the injectors.

You will re-connect them one at a time to do the testing. Once you have checked an injector lead, disconnect it before testing the next injector. Fail to do this and you will get incorrect results

Turn the ignition switch to Run

Check pins 37 & 57; you should see 12 volts.

Computer wiring harness connector, wire side

Computer wiring harness connector, computer side side

Here are the HO injector wires that are different; check to see that you have 12 volts on them one at a time.

Connect injector #3, look for 12 volts on pin 12 on the computer. Disconnect the injector connector from the injector before testing the next wire.

Connect injector #7, look for 12 volts on pin 42 on the computer. Disconnect the injector connector from the injector before testing the next wire.

Connect injector #5, look for 12 volts on pin 14 on the computer. Disconnect the injector connector from the injector before testing the next wire.

Connect injector #4. look for 12 volts on pin 13 on the computer. You are finished now and can reconnect all the injector connectors to the injectors.

Code 23 - Throttle sensor out of range or throttle set too high - TPS needs to be reset to below 1.2 volts at idle. Keep in mind that when you turn the idle screw to set the idle speed, you change the TPS setting.

You'll need a Digital Voltmeter (DVM) to do the job.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

Always use the Dark Green/lt green & Black/white wires to set the TPS base voltage.

Do the test with the ignition switch in the Run position without the engine running.

Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

When you installed the sensor make sure you place it on the peg right and then tighten it down properly. Loosen the back screw a tiny bit so the sensor can pivot and loosen the front screw enough so you can move it just a little in very small increments. I wouldn’t try to adjust it using marks. Set it at .6.v-.9 v.

1. Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

2. When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

If setting the TPS doesn’t fix the problem, then you may have wiring problems.

With the power off, measure the resistance between the black/white wire and battery ground. You should see less than 2 ohms. Check the same black /white wire on the TPS and MAP/Baro sensor. More than 1 ohm there and the wire is probably broken in the harness between the engine and the computer. The 10 pin connectors pass the black/white wire back to the computer, and can cause problems.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host)

See the graphic for the 10 pin connector circuit layout.

Code 95 Key On, Engine not Running - the following test path is for 86-90 model Mustangs.

The 95 code is because at one time or another, the fuel pump relay hiccupped and didn't provide power the pump when the computer told it to run. Sometimes this is a one time thing, other times it is a no run or runs poorly condition.

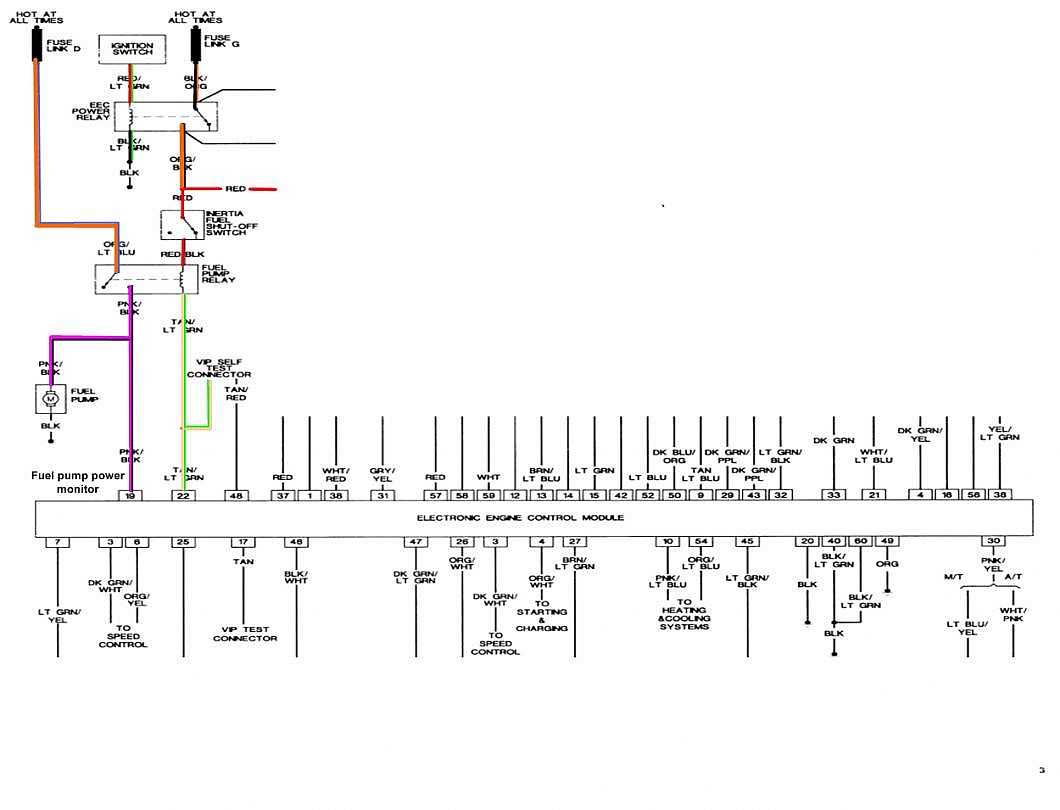

Using the diagram, check the red/black wire from the fuel pump relay: you should see 12 volts or so. If not, check the inertia switch: on a hatch it is on the driver’s side by the taillight. Look for a black rubber plug that pops out: if you don't find it, then loosen up the plastic trim. Check for voltage on both sides of the switch. If there is voltage on both sides, then check the Pink/black wire on the fuel pump relay: it is the power feed to the fuel pump. No voltage there, check the Orange/Lt blue wire, it is the power feed to the fuel pump relay & has a fuse link in it. If there is good voltage there & at the Pink/black wire, swap the relay.

Some Mass Air conversions neglect to run the extra fuel pump wire, and they always have a 95 code. See

http://www.stangnet.com/tech/maf/massairconversion.html for more information on the Mass Air wiring conversion.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/91-93_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pinout

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif