Sorry lol forgot you have a sump tank.... and yes the ms2 has provision for the e85 sensor, then yes we will need to set the e85 fuel table up. The table should have exactly the same curve, just higher numbers by about 30%

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

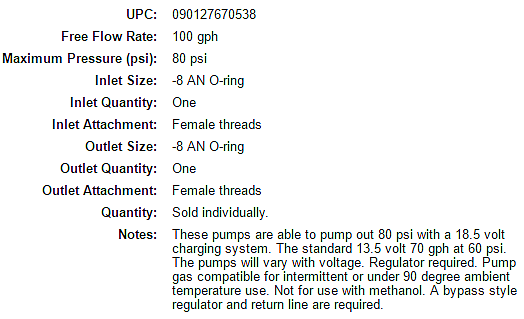

So,...WTF?......You read all of the disclaimers out there on Summit's website that fuel pumps have now, and it looks like the fuel itself is what is getting hot because of the recirculation...my 200.00 pump evidently doesn't like that. All of Holley's fuel pumps have this disclaimer..

Like this one:

Looks like it should work,....It's expensive enough..

Until you read this junk..

Pump gas compatible for intermittent use, or under 90 degree ambient temperature use? 80 p.s.i at 18.5 VOLTS!!!! What do I have to do,...carry a mini reactor to run the pump?

If your target is 600 engine HP on E85, that pump is not big enough. At 500 engine HP, that pump is not big enough. You also have to get a larger regulator and a larger return line. I assume the fuel injectors are large enough.

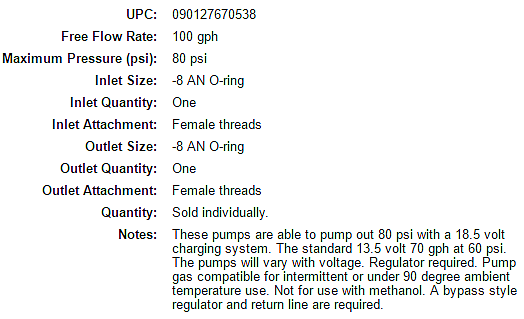

Like this one:

Looks like it should work,....It's expensive enough..

Until you read this junk..

Pump gas compatible for intermittent use, or under 90 degree ambient temperature use? 80 p.s.i at 18.5 VOLTS!!!! What do I have to do,...carry a mini reactor to run the pump?

If your target is 600 engine HP on E85, that pump is not big enough. At 500 engine HP, that pump is not big enough. You also have to get a larger regulator and a larger return line. I assume the fuel injectors are large enough.

600 hp????So,...WTF?......You read all of the disclaimers out there on Summit's website that fuel pumps have now, and it looks like the fuel itself is what is getting hot because of the recirculation...my 200.00 pump evidently doesn't like that. All of Holley's fuel pumps have this disclaimer..

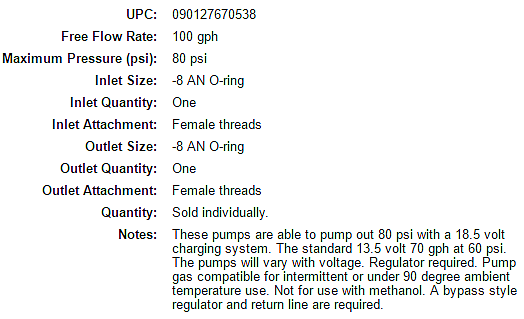

Like this one:

Looks like it should work,....It's expensive enough..

Until you read this junk..

Pump gas compatible for intermittent use, or under 90 degree ambient temperature use? 80 p.s.i at 18.5 VOLTS!!!! What do I have to do,...carry a mini reactor to run the pump?

If your target is 600 engine HP on E85, that pump is not big enough. At 500 engine HP, that pump is not big enough. You also have to get a larger regulator and a larger return line. I assume the fuel injectors are large enough.

This engine would never make 600 hp even if I rammed it full of nitromethane.

The target is whatever it'll make at 10 p.s.i.. E85 is only being considered because I probably have close to 11:1 cr., and a combustion chamber designed in 1980.

- Mar 2, 2015

- 6,811

- 5,849

- 203

Seems like the solution is simple....non ethenol fuel. Around here the marinas and some farm stores carry regular old 80s style plain gasoline...without the ethenol. That stuff wreaks havoc on everything that it touches. Especially, steal and rubber seals.

I buy mine from a farm store in VA every chance I get. The marinas fuel is about 3 bucks a gallon.

I buy mine from a farm store in VA every chance I get. The marinas fuel is about 3 bucks a gallon.

- Mar 2, 2015

- 6,811

- 5,849

- 203

http://www.pure-gas.org/index.jsp?stateprov=AL

This site has a list of all the stations near you that have good'ol gas

This site has a list of all the stations near you that have good'ol gas

Now just how is that "simple" solution? I can easily find e85, more so than straight non- E10/15 fuel. It's also easier to just plumb the thing for a water meth inj system thAn to find a marina every time I need gas.....your version of easy is much more of a pain in the ass than mine.Seems like the solution is simple....non ethenol fuel. Around here the marinas and some farm stores carry regular old 80s style plain gasoline...without the ethenol. That stuff wreaks havoc on everything that it touches. Especially, steal and rubber seals.

I buy mine from a farm store in VA every chance I get. The marinas fuel is about 3 bucks a gallon.

Why I oughtta.....

- Mar 2, 2015

- 6,811

- 5,849

- 203

Throw a couple gas cans in the Mini and go fuel huntin'. E85 isn't that common around here. There are marinas everywhere in my neck of dirty beaches.

E85 would be nice...if I could find it around here.

E85 would be nice...if I could find it around here.

I agree Mike let's water inject our cars..

I have already assembled a list.

I have already assembled a list.

The secret question is: how much water/methanol do you inject?I agree Mike let's water inject our cars..

I have already assembled a list.

How do you control the process?

Is it boost pressure, inlet air temp, throttle opening, RPM or a combination of 2 or more of these variables?

In our case I would set the parameters in tuner studio to inject based on kpa and possibly mat temps... since the megasquirt has multiple i/o I can program the output to trigger a relay.

Then the question of how much, based on manufacturer info I think the 5gph nozzles are a good starting point.

Then the question of how much, based on manufacturer info I think the 5gph nozzles are a good starting point.

The secret question is: how much water/methanol do you inject?

How do you control the process?

Is it boost pressure, inlet air temp, throttle opening, RPM or a combination of 2 or more of these variables?

In our case I would set the parameters in tuner studio to inject based on kpa and possibly mat temps... since the megasquirt has multiple i/o I can program the output to trigger a relay.

Then the question of how much, based on manufacturer info I think the 5gph nozzles are a good starting point.

Snow coolers' instruction sheets/injection references are available online, and their injection nozzles are available ala-carte. If I do this, I haven't read enough on the home made kits out there, but it's only 6 letters on the keyboard. G-O-O-G-L-E.

This one comes up immediately:http://www.turbomirage.com/water.html

I'm still between a rock and the proverbial hard place though,...I'll try and take the car out for a little bit today to see what might be going on w/ a datalog...While driving it back home Saturday, I could swear that a simple non-boosted load I was hearing it ping, As soon as I lifted that noise went away. I also think that I could also hear the BOV venting after I lifted in non-boosted situations. I don't know if I was hearing pinging, or rattles, or who knows what kinda other related harmonic crap, but if it's pinging while not in boost, and the BOV is venting as well,...I got all kinds of places to rule out.

The ONLY thing that changed after the oil hose leak that was related to cause this is that I added more length to the elbow that turned into the throttle body to give the hose clamps something to bite onto. The only possible scenario that I can even get my head around is that I was leaking boost....Now I'm not.

If that's the case,...I'm no longer at 10-11 pounds,.....I'm higher. The digital gauge sucks,.....It reads low compared to the DL, so watching it means nothing,......Just like half of the rest of the digital gauges.....They'll be changing this winter.

The other two "coincidental" changes are that my timing has changed,....I've got some bad gas,.....That sorry little boost controller is malfunctioning....

So we'll work backwards....It's easy enough to just remove the stupid little boost controller and drive the thing

If none of the other coincidentals exist, I'll have 7 p.s.i. again, and should have no perceptible rattle/ping. That will fix me for now until we get moved, (and I convince the wife to let me spend some of my paycheck)

If it does fix me, I have two things that I want.

#1. I want a new pump. I want one that doesn't howl like a dog after driving for 20 minutes....

The attraction of converting to E 85 is strong, but my lines are 3/8" and are aluminum.....Last time I looked into stuff like this I thought I heard/read that E85 is corrosive, and will leave a white residue inside the aluminum lines...Maybe that was straight meth???

#2. I want 3.31 gears,....This thing cruises really nicely w/ the converter locked up in OD,....It'd be nice to look down at the "I can't trust it tach" and see something in the 2000 RPM range at 75 MPH instead of the 3000 RPM i'm currently seeing now.

The T loc needs rebuilding as well, and that would be done at the same time..

Replacing the 3.73's w/ 3.31's will give me back my first gear. 4R70w's have a really steep 2.84 first gear as they were typically behind weanie little 3.8 l v6's....Now it's behind a not so weanie little 4.1 I6.....I could stand to scrub some gear off..

I know that the Boost addiction bug has bit me....I know that the comfortable numbness of 7 p.s.i will soon give way to the need to scratch a 10 p.s.i itch again....But then there'll be that rattle thing again...

Water Meth injection?...

I think you should pull 2-3* of timing from the curve, start at 80kpa-250kpa(or higher).

This will fix the ping/rattle issue straight off. Then assemble the water meth kit and tune it in.

Btw I found the same site to build my parts list

This will fix the ping/rattle issue straight off. Then assemble the water meth kit and tune it in.

Btw I found the same site to build my parts list

It's the freakin boost controller.......Before I left for this little trip, I actually reset the thing back almost half a turn.....

Max boost is still showing 13.3,....and the only reason that the other 12.3 boost spikes you see in this log don't go right back up there is because the engine is rattling, and I'm instantly lifting.

So,...I didn't do jack to that controller, and it has crept up from 10. something, to now over 13+!!! again,..this is AFTER I set it back a little... Again, who knows HOW much boost the engine was seeing on Saturday???

The tune goes where it's sposed to go,...AFR dips down into the high 11's, and timing is below 15 degrees....It's just too much boost for the gas, and the chamber design I'm guessing....(Although the getting sideways at 40-50 mph in second and third gear thing is a freakin kick in the ass)...

I'm really liking the fact that I think the HG is gonna hang in there, I was worried that a stock composite HG would never let me get anywhere near the pressure levels the engine has seen...

So then,...I gotta get a REAL boost controller,...One that can be trusted to stay where it's set, and not just arbitrarily creep up to where ever it decides to go.

Max boost is still showing 13.3,....and the only reason that the other 12.3 boost spikes you see in this log don't go right back up there is because the engine is rattling, and I'm instantly lifting.

So,...I didn't do jack to that controller, and it has crept up from 10. something, to now over 13+!!! again,..this is AFTER I set it back a little... Again, who knows HOW much boost the engine was seeing on Saturday???

The tune goes where it's sposed to go,...AFR dips down into the high 11's, and timing is below 15 degrees....It's just too much boost for the gas, and the chamber design I'm guessing....(Although the getting sideways at 40-50 mph in second and third gear thing is a freakin kick in the ass)...

I'm really liking the fact that I think the HG is gonna hang in there, I was worried that a stock composite HG would never let me get anywhere near the pressure levels the engine has seen...

So then,...I gotta get a REAL boost controller,...One that can be trusted to stay where it's set, and not just arbitrarily creep up to where ever it decides to go.

Attachments

I know you are using a cheapy manual boost controller-but-don't you have a boost controller in the MS not hooked up?It's the freakin boost controller.......Before I left for this little trip, I actually reset the thing back almost half a turn.....

Max boost is still showing 13.3,....and the only reason that the other 12.3 boost spikes you see in this log don't go right back up there is because the engine is rattling, and I'm instantly lifting.

So,...I didn't do jack to that controller, and it has crept up from 10. something, to now over 13+!!! again,..this is AFTER I set it back a little... Again, who knows HOW much boost the engine was seeing on Saturday???

The tune goes where it's sposed to go,...AFR dips down into the high 11's, and timing is below 15 degrees....It's just too much boost for the gas, and the chamber design I'm guessing....(Although the getting sideways at 40-50 mph in second and third gear thing is a freakin kick in the ass)...

I'm really liking the fact that I think the HG is gonna hang in there, I was worried that a stock composite HG would never let me get anywhere near the pressure levels the engine has seen...

So then,...I gotta get a REAL boost controller,...One that can be trusted to stay where it's set, and not just arbitrarily creep up to where ever it decides to go.

yeah i do,...(and it's hooked up, just no longer plumbed into the gates) It's the uncertainty of the circuit, not knowing whether or not i did it right,.. and considering that there is no dedicated circuit for the boost control mod,..you have to do what you can, choose one of a number of possible ways to hook it up, and hope it was hooked up right.

i have what i need to reimplement it,...i just wish there was a way to check it instead of just letting the circuit do what it might do, (poof) and what it might not do. (boom)

i have what i need to reimplement it,...i just wish there was a way to check it instead of just letting the circuit do what it might do, (poof) and what it might not do. (boom)

Water injection control system ideas

Some more Google using a better search definition ( ratio between water and gasoline in water injection ) yielded this gem:

http://www.autospeed.com/cms/article.html?&title=The-H2O-Way-Part-2&A=110213 .

This said that best results were achieved by using .5-.6 parts water to1 part gasoline ratio. That means at .5 for every gallon of fuel you burn that 64 fl.oz. of water is consumed.

At .6 parts water to1 part gasoline ratio means at .6 for every gallon of fuel you burn that 76.8 fl.oz. of water is consumed.

If you stay in the boost arena, you are going to consume a lot of water...

The only accurate way to meter the amount of water needed is to know how much fuel in GPM or LPM is being consumed.

That is achieved by measuring the pressure drop across an orifice with a fixed constant pressure applied to the gasoline. You'll need an electronic pressure sensor to get usable information to your flow control system.

A similar setup will be needed to measure the volume of water. The flow control system will vary the pressure of the water pump to provide the correct ratio of water to fuel and turn the water pump on and off and regulate the water pressure by using a PWM (Pulse Width Modulation) output to the pump.

Or you can simplify and let fluid mechanics do the work for you.

See http://www.tlv.com/global/TI/calculator/water-flow-rate-through-orifice.html. You'll end up with a pressure regulator that senses pressure at the input of an orifice on one side of the diaphragm or piston and pressure at the output of the orifice. That diaphragm or piston will open or close a needle valve that controls the water flow in proportion to the gasoline flow. You'll still need a pressure sensor switch to turn the water pump on and off.

For those of you not familiar with PWM, here's some help.

Some more Google using a better search definition ( ratio between water and gasoline in water injection ) yielded this gem:

http://www.autospeed.com/cms/article.html?&title=The-H2O-Way-Part-2&A=110213 .

This said that best results were achieved by using .5-.6 parts water to1 part gasoline ratio. That means at .5 for every gallon of fuel you burn that 64 fl.oz. of water is consumed.

At .6 parts water to1 part gasoline ratio means at .6 for every gallon of fuel you burn that 76.8 fl.oz. of water is consumed.

If you stay in the boost arena, you are going to consume a lot of water...

The only accurate way to meter the amount of water needed is to know how much fuel in GPM or LPM is being consumed.

That is achieved by measuring the pressure drop across an orifice with a fixed constant pressure applied to the gasoline. You'll need an electronic pressure sensor to get usable information to your flow control system.

A similar setup will be needed to measure the volume of water. The flow control system will vary the pressure of the water pump to provide the correct ratio of water to fuel and turn the water pump on and off and regulate the water pressure by using a PWM (Pulse Width Modulation) output to the pump.

Or you can simplify and let fluid mechanics do the work for you.

See http://www.tlv.com/global/TI/calculator/water-flow-rate-through-orifice.html. You'll end up with a pressure regulator that senses pressure at the input of an orifice on one side of the diaphragm or piston and pressure at the output of the orifice. That diaphragm or piston will open or close a needle valve that controls the water flow in proportion to the gasoline flow. You'll still need a pressure sensor switch to turn the water pump on and off.

For those of you not familiar with PWM, here's some help.

Last edited:

Annnnd just like that,...I'm back to square 1. Square 1 in this case is 7 p.s.i.

This is "old faithful".The T in front of that boost control solenoid shows the lower port of the gate straight line pressure and will net me 7 p.s.i.

The red line after the solenoid will add whatever pressure that the solenoid pulses to the top port of the gate to "restrict" the opening rate of the thing to net me whatever is set up in Tuner Studio....

If this sht works, and I don't fry the ECU, or blow the engine up.

This is "old faithful".The T in front of that boost control solenoid shows the lower port of the gate straight line pressure and will net me 7 p.s.i.

The red line after the solenoid will add whatever pressure that the solenoid pulses to the top port of the gate to "restrict" the opening rate of the thing to net me whatever is set up in Tuner Studio....

If this sht works, and I don't fry the ECU, or blow the engine up.

Quiet you,....Glad youre ditching the digital gauges... again.

I never liked digital gauges myself.Glad youre ditching the digital gauges... again.

I'll be quiet now too.

- Status

- Not open for further replies.