Hey Guys,

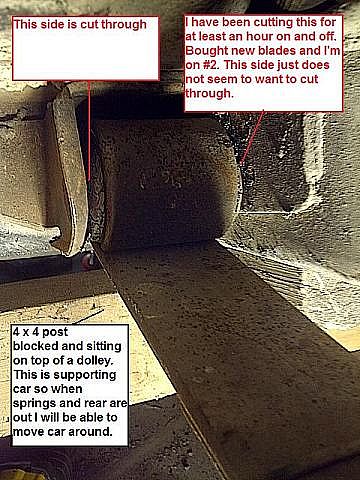

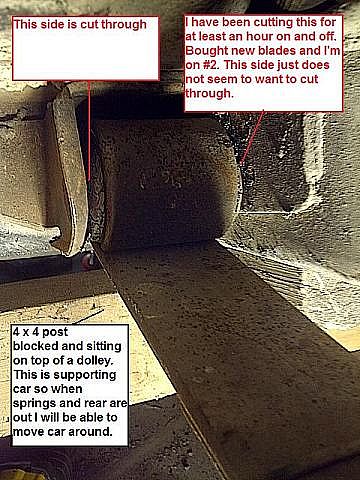

Ok I read all the comments on how frustrating it can be to remove the leaf springs. Let me just say OMG I think this is the most frustrating thing I have done yet. I'm using a recip saw with heavy duty Bosch metal cutting blades. The outboard side took a good 20 min. Been working on the inside for over an hour, on my 3rd blade and it just won't break loose. Any suggestions (besides narcotics)??

Pic below....

Ok I read all the comments on how frustrating it can be to remove the leaf springs. Let me just say OMG I think this is the most frustrating thing I have done yet. I'm using a recip saw with heavy duty Bosch metal cutting blades. The outboard side took a good 20 min. Been working on the inside for over an hour, on my 3rd blade and it just won't break loose. Any suggestions (besides narcotics)??

Pic below....

the rubber will burn and smoke badly, dont breath it.

the rubber will burn and smoke badly, dont breath it.

I'll keep you posted.

I'll keep you posted. I've certainly had less luck on other cars. A "heat wrench" (oxy/acetylene torch) gives a good level of satisfaction! Just be ready to do all the cutting quickly and have all other stuff cleared away so that you can knock the old stuff out quickly and get it done in one fell swoop! Once you're set up, its a 2 minute job per bolt.

I've certainly had less luck on other cars. A "heat wrench" (oxy/acetylene torch) gives a good level of satisfaction! Just be ready to do all the cutting quickly and have all other stuff cleared away so that you can knock the old stuff out quickly and get it done in one fell swoop! Once you're set up, its a 2 minute job per bolt. ), new u-bolts for $234.00.

), new u-bolts for $234.00.