In this build I will show the good and bad features of building a Dynacorn body.

My customer has wanted a Fastback Mustang for a long time but could not find a good body that did not require a lot of rust repair so he decided to buy a 1967 Dynacorn body. He started calling around and could not find a body back in January. He called Dynacorn and they told him they had no idea when they would get one in. He was getting discouraged and had to go back to work where he works 10 weeks and than is off 10 weeks. When he got back in town he started checking around and still nobody had one. He found a project that was never started that came with a lot of extra parts so he bought it.

Some of the good points are the shock tower braces, extra welding in the engine compartment and a lot more spot welds and the export brace

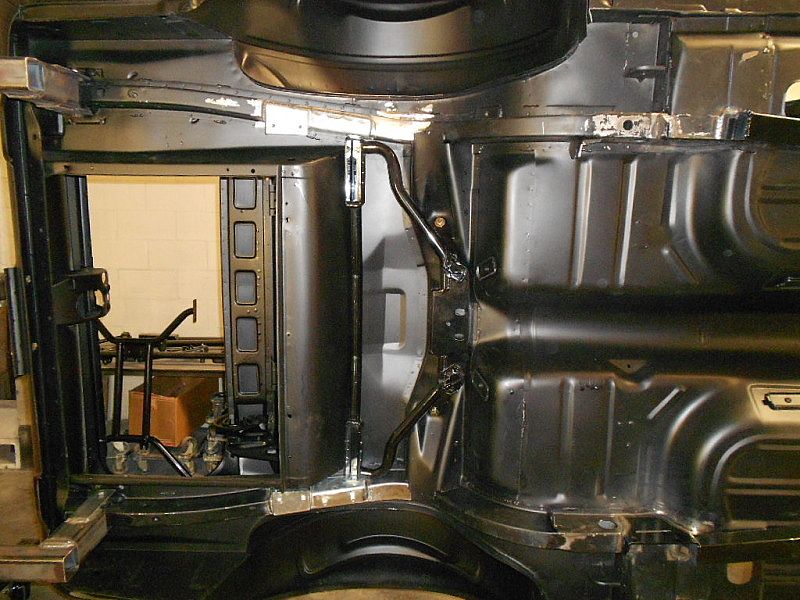

Another good feature is the one piece seat riser.

I have never seen an after market valance fit this good but it is bolted together instead of screws.

My customer has wanted a Fastback Mustang for a long time but could not find a good body that did not require a lot of rust repair so he decided to buy a 1967 Dynacorn body. He started calling around and could not find a body back in January. He called Dynacorn and they told him they had no idea when they would get one in. He was getting discouraged and had to go back to work where he works 10 weeks and than is off 10 weeks. When he got back in town he started checking around and still nobody had one. He found a project that was never started that came with a lot of extra parts so he bought it.

Some of the good points are the shock tower braces, extra welding in the engine compartment and a lot more spot welds and the export brace

Another good feature is the one piece seat riser.

I have never seen an after market valance fit this good but it is bolted together instead of screws.

Seriously though, It's nice to see you and Brian getting to work on something that isn't a rot box/rust bucket. By the way, any more pics of that gorgeous green Shelby fastback you were doing? Is it done, or in wating mode?

Seriously though, It's nice to see you and Brian getting to work on something that isn't a rot box/rust bucket. By the way, any more pics of that gorgeous green Shelby fastback you were doing? Is it done, or in wating mode?

There oughta be a F---ing law! I've experienced that kind of crap before and it just plain pisses me off. The one that got me the most was 2 seemingly identical rear wheel cylinders, both from the same company with the same part numbers, SAE threads for the bolts, standard brake line. One of them took a regular 5/16" wrench for the bleeder and the other needed a 10mm metric wrench!

There oughta be a F---ing law! I've experienced that kind of crap before and it just plain pisses me off. The one that got me the most was 2 seemingly identical rear wheel cylinders, both from the same company with the same part numbers, SAE threads for the bolts, standard brake line. One of them took a regular 5/16" wrench for the bleeder and the other needed a 10mm metric wrench!