You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Fairmont. I bet somebody back home’s thinkin’…I wonder why he don’t write..?

- Thread starter CarMichael Angelo

- Start date

-

Sponsors (?)

Im starting to think you're right.I think a 6266 or 6466 precision would’ve done exactly what you wanted and then some.

Fwiw... I have a bunch of the stickshift mafia guys running in the 6's in the 1/8 with 67mm turbos and STOCK LONG BLOCKS.... that's right e7 heads and stock cam in most cases.

Are you draggin irrelevant junk from another thread into my pristine, info laden, techno thread?Fwiw... I have a bunch of the stickshift mafia guys running in the 6's in the 1/8 with 67mm turbos and STOCK LONG BLOCKS.... that's right e7 heads and stock cam in most cases.

The locker is here, along with the bearing set. According to UPS, the axles, and housing ends will be here tomorrow.

If I had the Jig, and actually knew what I was doing, I could do the rear end on Sunday. Cutting the ends off the axles, and re welding the small bearing ford ends back on are NOT the issue for me believe it or not..I’m completely confident that I can do that...It’s the process involved with setting up the rear end that I’m conflicted about.

I’ve watched a few “ how to set up an 8.8” vids now, and it seems juussttt a little beyond my reach.

I don’t have the pinion setup bearing that’ll slide on/off the pinion to set pinion depth.

I don’t have a press to put the bearings on...

I don’t have an inch pound torque wrench to check pinion drag on the bearing.

I don’t know what people are seeing when they look at the gear tooth pattern...I just can’t get a clear understanding of what they show.

I don’t know that the ”put it together, ck it for backlash, take it apart, change the shims, put it together, ck it for backlash, take it apart,put it together, check it for backlash ” THEN put it together for real, and THEN check the contact pattern...and if that’s WRONG........take it back apart.......

Wouldn’t have me draggin the rearend to the end of my drive way, and rolling it down the hill behind my house.

Lets remember: I do sht over and over when there is no expectation that it has to be done more than one time....When it’s expected that you are doing it over, my process would go to the “ over, and over, and over.........

Yet,...if I can borrow my friends housing jig today, or tomorrow.... i’m gonna do just that.

If I had the Jig, and actually knew what I was doing, I could do the rear end on Sunday. Cutting the ends off the axles, and re welding the small bearing ford ends back on are NOT the issue for me believe it or not..I’m completely confident that I can do that...It’s the process involved with setting up the rear end that I’m conflicted about.

I’ve watched a few “ how to set up an 8.8” vids now, and it seems juussttt a little beyond my reach.

I don’t have the pinion setup bearing that’ll slide on/off the pinion to set pinion depth.

I don’t have a press to put the bearings on...

I don’t have an inch pound torque wrench to check pinion drag on the bearing.

I don’t know what people are seeing when they look at the gear tooth pattern...I just can’t get a clear understanding of what they show.

I don’t know that the ”put it together, ck it for backlash, take it apart, change the shims, put it together, ck it for backlash, take it apart,put it together, check it for backlash ” THEN put it together for real, and THEN check the contact pattern...and if that’s WRONG........take it back apart.......

Wouldn’t have me draggin the rearend to the end of my drive way, and rolling it down the hill behind my house.

Lets remember: I do sht over and over when there is no expectation that it has to be done more than one time....When it’s expected that you are doing it over, my process would go to the “ over, and over, and over.........

Yet,...if I can borrow my friends housing jig today, or tomorrow.... i’m gonna do just that.

I am about to attempt this myself as well. I’ve watched all the Eric the Car Guy vids several times. I also printed and read the Ford manual on re-doing the 8.8.

If I was at 600hp, I’m not sure I’d be doing it myself, but for my application I’m giving it a shot.

I have my rain check for $119.99 on the Harbor Freight shop press, so once its back in stock, I’ll get started.

I say you go for it Mike!!

If I was at 600hp, I’m not sure I’d be doing it myself, but for my application I’m giving it a shot.

I have my rain check for $119.99 on the Harbor Freight shop press, so once its back in stock, I’ll get started.

I say you go for it Mike!!

maybe.. not sure anymore.Are you draggin irrelevant junk from another thread into my pristine, info laden, techno thread?

The spats look really good BTW... nice job. I am considering doing something with my bumper cover so I can do turn downs I really dont want to do side exit from the bumper cover... if it rains sideways [normal occurrence in FL] the exhaust housing may fill with water..

I've done several 9" and 8.8" but you really need to have all the correct tools. Its not terrible complicated. The hardest part is looking at your coast and drive pattern and knowing what direction you need to move to correct. There are some good charts online to show if pattern is like this then move pinion back etc... I always start with the shims etc that i took out when i tore it apart and thats usually a good starting point

Last edited:

- Mar 2, 2015

- 6,811

- 5,849

- 203

Once you've done a few of them its not that bad at all. The pattern is the most important thing...it says it all. A dial indicator is a must for back lash for most people. Usually with frpp gears the original shims get you just about right where you want it.

I saddle those 8.8s on Jack stands over a drain pan. A third stand is used under the pinion area to pick the nose up for the drag check, or a jack. It's gotten to the point where I go by feel and no longer need to check backlash or pinion drag with tools.

Setting pinion depth is done on its own...this is what I have used for years. Gets rid of the crush washer.

Get the old bearings pressed off an sand the hell out of the inside until they slide on and off the pinion. Now you have bearings to set the rear up with.

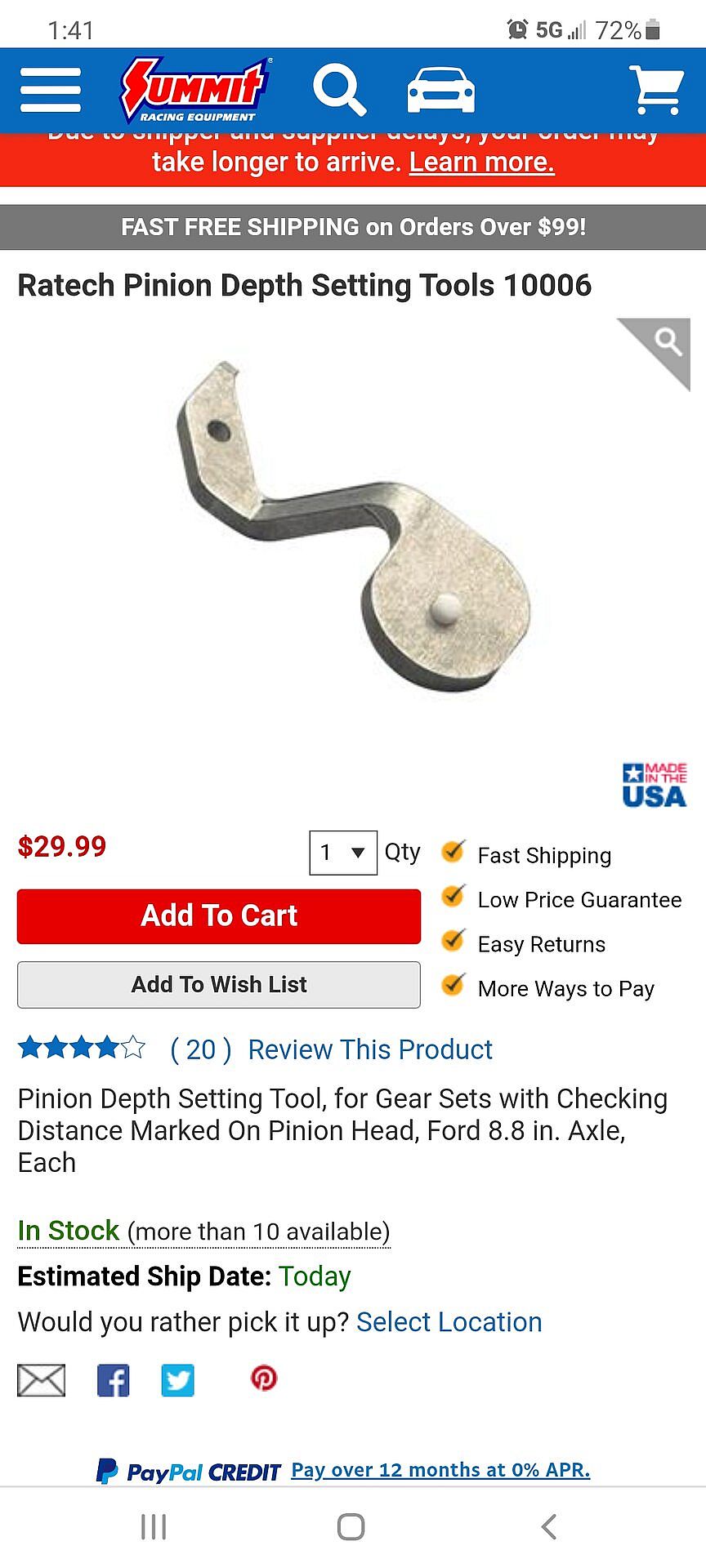

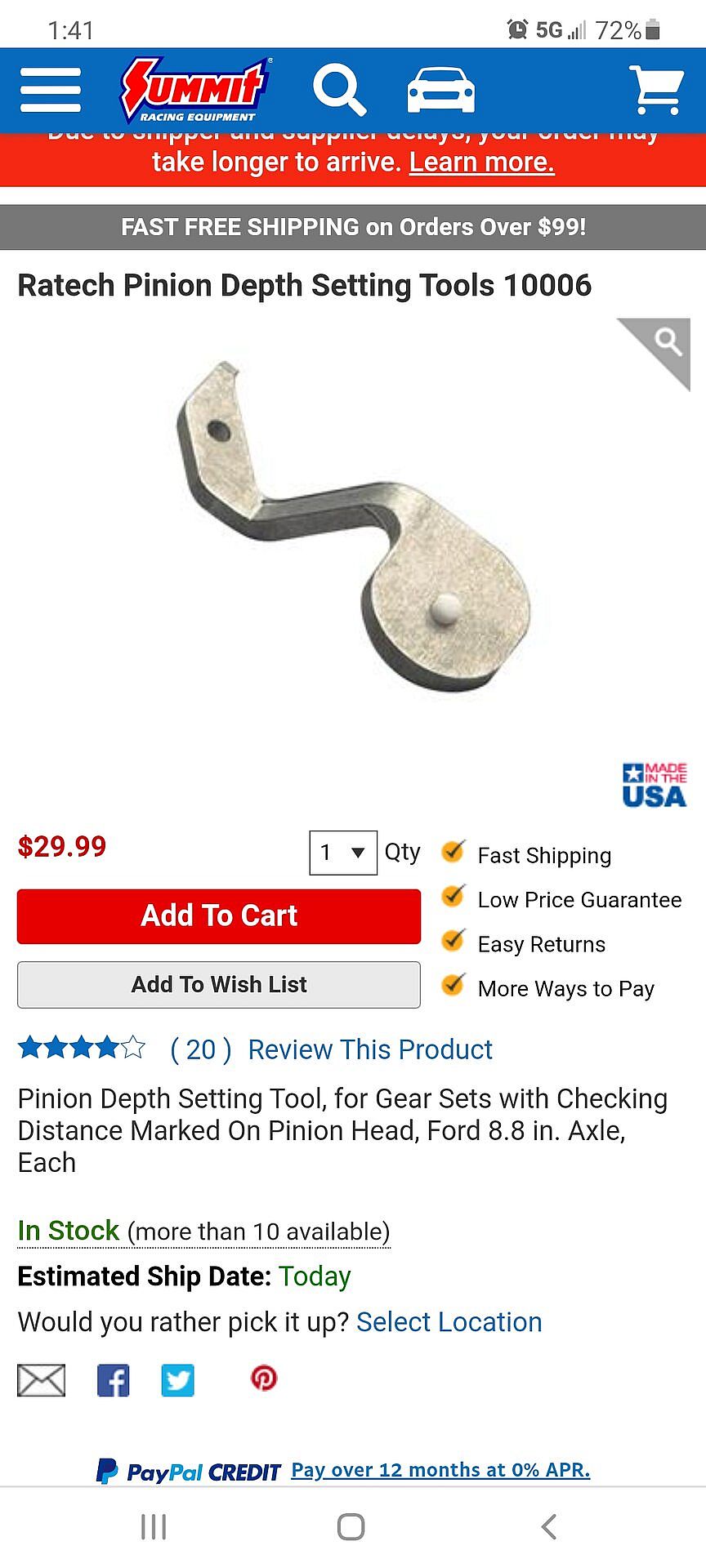

This booger comes in handy too. Is used with dial indicator to set pinion depth. I only use crush washers when the customer is street driving with around stock hp.

For anyone only doing gears one time it really isn't worth it to buy the tools and take the risk of messing up.

Mike, likes doing things over and over so this should keep him occupied for a few days.

Come on man, you just made metal spats and built an engine that wasn't supposed to work at all. You can do this.... we believe in you.

If you don't set up your gears we will always remember the one thing you could not do.

I saddle those 8.8s on Jack stands over a drain pan. A third stand is used under the pinion area to pick the nose up for the drag check, or a jack. It's gotten to the point where I go by feel and no longer need to check backlash or pinion drag with tools.

Setting pinion depth is done on its own...this is what I have used for years. Gets rid of the crush washer.

Get the old bearings pressed off an sand the hell out of the inside until they slide on and off the pinion. Now you have bearings to set the rear up with.

This booger comes in handy too. Is used with dial indicator to set pinion depth. I only use crush washers when the customer is street driving with around stock hp.

For anyone only doing gears one time it really isn't worth it to buy the tools and take the risk of messing up.

Mike, likes doing things over and over so this should keep him occupied for a few days.

Come on man, you just made metal spats and built an engine that wasn't supposed to work at all. You can do this.... we believe in you.

If you don't set up your gears we will always remember the one thing you could not do.

Last edited:

Well...just in case you’ve read how I interact with others here, and thought to yourself.....

” I’ll bet that guy’s a real fckin prick in person”...

I’m here to remind you...Don’t judge a book by its cover.

Called my TLF, and asked him if I could borrow, or rent his housing jig this morning, and he tells me straight away,..

“You cannot rent my jig, you ass......but you can borrow it”

What a guy..

Or maybe,....just maybe ...I’m not as big of a prick as I might seem.

Then again,...I do have my ”rougher edges”.

Anyway,..I digress.

I talk to him about what I’m considering..We talk about the fact these gears were newly installed when the monster was still just a little desert lizard about 6 years ago. And despite the fact that it was 6 years ago, the collective mileage that is on that gear set is a relatively easy 1500-2000 miles.

Which brought about the question, “Why would I even need to remove the pinion nut?”

While we sat there discussing that, we also talked about how likely it was that there wouldn’t be a crush sleeve in the current install, since he hasnt used a crush sleeve in his gear installs for a long time...and mine would more than likely have a solid spacer as well.

So,..even if I choose to remove the thing to install a new seal, and nut, I should be able to put it back the way It came apart.

But in case I did decide to take it apart, and found that it did have a crush sleeve...He also lets me borrow Thor..

1100 ft lbs, of steel snappin‘ cordless torque..

He tells me to “ be careful”

I wonder where the “ be careful” setting is on a 1100 ft/lb impact gun..?

I still have to get the rear out, and get it disassembled..I still have to cut the housing ends off and weld the new ends back on..Knowing me..That’ll be the entire day Sunday..I may never even get to messing with the gear setup till the next Thursday...I’ve still gotta buy a press, I have the dial indicator and mag-base..I don’t have an inch pound torque wrench, but im going to HF for the press, the torque wrench is only another 20 bucks.

No matter,..I still have no disposition on the Turbo..The exhaust manifold has been open for 2 weeks come Sunday. I’m seeing a 64/66mm .81 A/R Chinee ball bearing turbo on the horizon..

” I’ll bet that guy’s a real fckin prick in person”...

I’m here to remind you...Don’t judge a book by its cover.

Called my TLF, and asked him if I could borrow, or rent his housing jig this morning, and he tells me straight away,..

“You cannot rent my jig, you ass......but you can borrow it”

What a guy..

Or maybe,....just maybe ...I’m not as big of a prick as I might seem.

Then again,...I do have my ”rougher edges”.

Anyway,..I digress.

I talk to him about what I’m considering..We talk about the fact these gears were newly installed when the monster was still just a little desert lizard about 6 years ago. And despite the fact that it was 6 years ago, the collective mileage that is on that gear set is a relatively easy 1500-2000 miles.

Which brought about the question, “Why would I even need to remove the pinion nut?”

While we sat there discussing that, we also talked about how likely it was that there wouldn’t be a crush sleeve in the current install, since he hasnt used a crush sleeve in his gear installs for a long time...and mine would more than likely have a solid spacer as well.

So,..even if I choose to remove the thing to install a new seal, and nut, I should be able to put it back the way It came apart.

But in case I did decide to take it apart, and found that it did have a crush sleeve...He also lets me borrow Thor..

1100 ft lbs, of steel snappin‘ cordless torque..

He tells me to “ be careful”

I wonder where the “ be careful” setting is on a 1100 ft/lb impact gun..?

I still have to get the rear out, and get it disassembled..I still have to cut the housing ends off and weld the new ends back on..Knowing me..That’ll be the entire day Sunday..I may never even get to messing with the gear setup till the next Thursday...I’ve still gotta buy a press, I have the dial indicator and mag-base..I don’t have an inch pound torque wrench, but im going to HF for the press, the torque wrench is only another 20 bucks.

No matter,..I still have no disposition on the Turbo..The exhaust manifold has been open for 2 weeks come Sunday. I’m seeing a 64/66mm .81 A/R Chinee ball bearing turbo on the horizon..

I have the Harbor Freight press. It works fine. Pressed all 437 bushings in a BMW together with it.

Kurt

Kurt

Let's see it happen! Get those gears swapped onto the new carrier and the  welded up and put back

welded up and put back

welded up and put back

welded up and put backHotFox

15 Year Member

I'm waiting for the build to take turn...pull the turbo sell all the turbo stuff and go naturally aspirated! It seems like we are to that point again? Come on Mike doesn't this engine make enough steam NA? You were pretty convinced last time!

This engine has never been N/A. I’m not even happy with the current power level @22 psi...In what bizarro parallel universe would I go backwards on this engine?I'm waiting for the build to take turn...pull the turbo sell all the turbo stuff and go naturally aspirated! It seems like we are to that point again? Come on Mike doesn't this engine make enough steam NA? You were pretty convinced last time!

HotFox

15 Year Member

Last time I had 260c.i., an almost 11:1 cr, and a 4” stroke. And I wanted an engine that would look like this:But...But you did last time for no apparent reason! I found it rather entertaining!

Only not as blurry...

And then, I came to my senses...

And Ultimately..i completely became all seeing..

And almost became able to see the future ........I could see so clearly...

This time, the engine doesn’t even measure 200 c.i., Barely makes 9:1 cr, and has a a little over a 3” stroke. As slow as it is with a small turbo that spools almost instantly, it would be mind numbingly slow w/o one.

Last edited:

it’ll be the only thing i can guarantee that i won’t ever do more than once.The thing about pulling off the turbo and going N/A is…you haven’t done it twice yet.

I PM’d Noobz this morning. It was my intention to bring the old thread back, and merge it with this new rambling collection of head bumps, and mild wins..

Turns out that the old thread has gotten old, and has gotten really slow to open, which pretty much rains on my plan..

MY ORIGINAL PLAN was to lean the babble down, and do a separate tech thread, and leave the new one for all of the drunken debauchery ( mostly coming from me). I was gonna pair the original down, and take the good stuff and put it there, But for all of the stuff that was done before, none of that remains.....nothing.

It wasn’t very far in before the thought process overwhelmed me...and left me thinking “Why the hell am I talking about sht that was done, that ain’t there anymore?”

So,..the lazy side of my ass PM’s Noobz this morning..I’ve given up on cutting out small snippets of history for the sake of consolidating stuff that ain’t there no more. On top of that, The stuff I’d cut out would end up leaving a lot of the good sht on the cutting room floor, and I’m proud of the good sht.......it just didn’t make no damn sense. That’s why I asked him to bring it forward, so I could put the current one in front, and let what was, be what was...on the back.

But like I said,..The old thread has gotten dimensia. It takes forever to open the first page, and every other page after that..So I have to keep it separate until there’s some cure for the dimensia in the old thread, before I can bring him safely to the dinner table..

Turns out that the old thread has gotten old, and has gotten really slow to open, which pretty much rains on my plan..

MY ORIGINAL PLAN was to lean the babble down, and do a separate tech thread, and leave the new one for all of the drunken debauchery ( mostly coming from me). I was gonna pair the original down, and take the good stuff and put it there, But for all of the stuff that was done before, none of that remains.....nothing.

It wasn’t very far in before the thought process overwhelmed me...and left me thinking “Why the hell am I talking about sht that was done, that ain’t there anymore?”

So,..the lazy side of my ass PM’s Noobz this morning..I’ve given up on cutting out small snippets of history for the sake of consolidating stuff that ain’t there no more. On top of that, The stuff I’d cut out would end up leaving a lot of the good sht on the cutting room floor, and I’m proud of the good sht.......it just didn’t make no damn sense. That’s why I asked him to bring it forward, so I could put the current one in front, and let what was, be what was...on the back.

But like I said,..The old thread has gotten dimensia. It takes forever to open the first page, and every other page after that..So I have to keep it separate until there’s some cure for the dimensia in the old thread, before I can bring him safely to the dinner table..

Last edited:

Similar threads

- Replies

- 18

- Views

- 2K

- Replies

- 3

- Views

- 828

- Replies

- 0

- Views

- 4K

- Replies

- 12

- Views

- 2K

Progress Thread

Dirty Water Racing 89 Notch Project

- Replies

- 64

- Views

- 10K